Editors’ Picks

Found in Robotics News & Content, with a score of 7.85

…can double or triple productivity, with less labor and ergonomic strain than traditional piece-handling systems. Sessions to discuss RaaS, flexibility Locus Robotics said its Logistics Summit sessions will highlight how its AMRs and robotics-as-a-service (RaaS) model can optimize efficiency during peak periods and beyond. The company's experts will also demonstrate how its robots can work with warehouse staffers to improve productivity, consistency, and throughput. Mischa Pick, business development manager at Locus, will present in the session entitled “Scalable, Flexible, Future-Proof—The Advantages of Robots-as-a-Service for Your Intralogistics.” He will describe how the company's RaaS model enables automation deployment without major upfront…

Found in Robotics News & Content, with a score of 3.10

…are designed to enhance a worker’s productivity and improve ergonomics and workplace safety. Locus bots seamlessly work alongside human teammates; they do not replace them. With less walking, lifting, or pulling heavy carts, people can focus on what they do best – picking and putaway. Customers have repeatedly shared feedback on how our collaborative robots do more than improve productivity; they dramatically improve the work environment, which leads to higher worker satisfaction and increased retention. Heffner: HMI is really critical to successful AMR [autonomous mobile robot] deployment. Employees who work around the robots have to be aware of safety and…

Found in Robotics News & Content, with a score of 3.84

…optimize the existing workforce productivity while also improving worker ergonomics and overall workplace quality.” “By collaborating with human workers, our robots minimize unproductive walking time, pulling heavy carts and lifting to free up employees for more value-added work,” she told Robotics 24/7. While complaints about labor shortages may seem universal, location matters, noted Joe Oliaro, vice president of sales and chief real estate officer at Wagner Logistics. “It depends,” he said. “In smaller markets where the community depends on a manufacturer – whether it’s Fortune 100 or local – companies are more willing to collaborate with labor because there’s a…

Found in Robotics News & Content, with a score of 5.43

…has involved employees who “want to evolve” in the ergonomics of the order-picking workstation. G2P system designed to maximize performance, wellness Ultimately, SCALLOC’s 300 sq. m (3229.1 sq. ft.) automated surface area will be fully screened and located on a concrete mezzanine above the loading docks. It will store and manage over 1,500 SKUs, from spirits to point-of-purchase (POP) items of various sizes and B and C rotation. The mezzanine will feature 130 mobile shelves, transported by five robots to two picking and replenishment stations. SCALLOG said its G2P system will guarantee V and B optimum security across its entire…

Found in Robotics News & Content, with a score of 9.48

…and efficiency, robots also help create safer and more ergonomic workplaces. As a result, employees can avoid tedious and risky tasks, focus on more value-added activities, and enjoy a more collaborative and satisfying work environment, asserted Geek+ and Körber in a release. Partnership produces results for customers Geek+ entered its first global partnership with Körber in 2020 and has rapidly expanded its offerings since then. The companies cited the deployment of 30,000 robots they said saved 140,000 tons of carbon emissions and 16 million KwH in energy in 2022. Together with Geek+’s growing robotics portfolio, Körber said its systems can…

Found in Robotics News & Content, with a score of 6.26

…and productivity, accurate fulfillment, reduced labor costs, safety and ergonomics, and space optimization.” “With a robust data collection and analytics process, all these benefits equip Newegg with a competitive advantage and a better customer experience,” he added. By taking on tedious or hazardous tasks, the robots allow associates to be reassigned to more complex and value-added activities that require greater problem-solving, decision-making and cognitive skills, Geek+ said. The robots also reduce physical strain and risk of injuries common among manual picking processes. In addition, employees have acquired new skills to supervise and maintain the robots while evaluating how they operate…

Found in Robotics News & Content, with a score of 9.87

…committee to guide their designs, covering topics like wear, ergonomics, environmental conditions, and load handling. The overall competition saw the University of Central Lancashire (UCLan) take first place, followed by the Vrije Universiteit Brussel in second and Clemson University in third. UCLan previously won an engineering award for an exoskeleton project in 2021. Several other special awards were also given to the following teams: Teams’ Choice Award: Federal University of Technology—Parana and Pontifícia Universidade Católica do Paraná Poster Competition Award: UCLan Presentation Competition Award: Clemson University Design Competition Award: Vrije Universiteit Brussel About the ASTM ET CoE Established in 2019,…

Found in Robotics News & Content, with a score of 7.18

…with human warehouse associates, enhancing fulfillment efficiency, improving workplace ergonomics, and doubling or tripling productivity. The company said its advanced algorithms and real-time data analysis enable companies to optimize their warehouse layouts, reduce travel times, and increase picking accuracy rates, ultimately resulting in faster order processing and reduced operational costs. The LocusOne platform uses AI and data science to smoothly orchestrate enterprise-scale, multi-form-factor automation within a single coordinated platform, said Locus Robotics. LocusOne is designed to optimize robotic task allocation, route planning, and resource use while delivering real-time insights into warehouse operations. Locus said that it supports more than 120…

Found in Robotics News & Content, with a score of 6.23

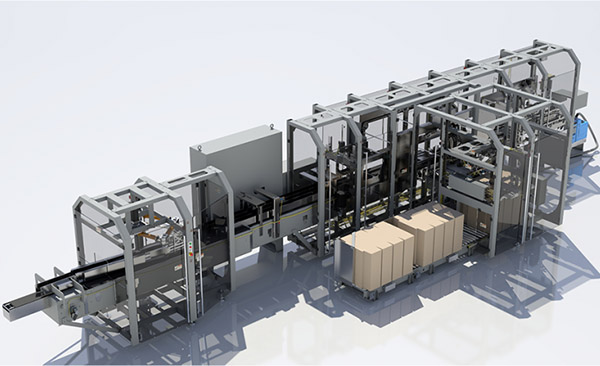

…interface features two-touch navigation to most commonly used functions. Ergonomic blank load system – The conveyor feed case blank loading system accepts three 26-in. stacks of blanks at a time. The XCP Series includes the XCP-30, XCP-40, and the XCP-C30, which are customized versions of the case packer. Brenton said the addition of the XCP Series to its case-packing portfolio “gives customers a reliable option with speeds reaching up to 70 cases per minute that is competitively priced and ready to perform.” The XCP Series is designed for easy access to all areas. Source: Brenton Brenton at PACK EXPO 2023…

Found in Robotics News & Content, with a score of 6.18

…robots to move goods between high-density storage racks and ergonomic picking stations. Skypod can increase warehouse throughput up to fivefold with two-minute or less response times for all SKUs, claimed Exotec. The goods-to-person system is fully modular, allowing customers to deploy in a matter of weeks and easily expand without interrupting production by simply adding robots, stations, or racks, it added. Exotec said that it has been rapidly expanding, with operations in 15 countries supporting more than 30 leading brands spanning the e-commerce, grocery, retail, manufacturing, and third-party logistics (3PL) industries. European expansion continues Exotec has been active in Eastern…

Found in Robotics News & Content, with a score of 12.25

…that uses robots moving goods between high-density storage and ergonomic stations. The system significantly shortens fulfillment times by automating highly manual tasks like walking and lifting heavy objects. acca international, and Exotec will collaborate to deliver a solution that meets PAL’s warehousing and shipping needs. acca international will provide fulfillment services to a warehouse that has adopted the Skypod system, aiming to effectively manage a distribution warehouse for clothing, everyday items, and other products from PAL Co., ltd. acca to support Skypod system customers Tokyo-based acca international, a third-party logistics (3PL) company, said it supports the functioning of e-commerce clothing…

Found in Robotics News & Content, with a score of 7.26

…and technology awards, the company claimed that its systems can dramatically increase productivity, lower operational costs, and improve workplace ergonomics. Supporting more than 100 of the world's top brands and deployed at over 250 sites around the world, Locus Robotics said enables retailers, third-party logistics providers (3PLs), and specialty warehouses to efficiently meet and exceed the increasingly complex and demanding requirements of today's fulfillment environments. Editor's note: For more about Automate 2023, visit Robotics 24/7's special coverage page.