Editors’ Picks

Found in Robotics News & Content, with a score of 10.42

…the best cobot for an industrial process such as sanding or assembly. When selecting a cobot, the first question to answer is what are you trying to do with the cobot? The answer to that question will help determine what attributes are most important to you. Once you have answered this question, consider the following factors, evaluated with level of importance for your application, to narrow down your options. Force-controlled or force-limited: All cobots are force-limited, but not all cobots are force-controlled. If you are solely worried about safety, force-limited is fine. However, if you want to use force control…

Found in Robotics News & Content, with a score of 10.17

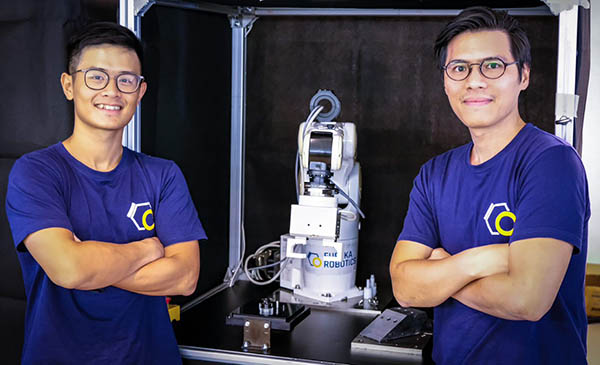

…by humans, such as assembly, fine manipulation, polishing, or sanding,” explained Pham Quang Cuong, an associate professor at NTU Singapore and co-founder of Eureka Robotics. “These tasks all share a common characteristic: the ability to maintain consistent contact with a surface.” “If our human hands are deprived of our touch sensitivity, such as when wearing a thick glove, we would find it very hard to put tiny Lego blocks together, much less assemble the tiny components of a car engine or of a camera used in our mobile phones,” said Pham, who is also the deputy director of the Robotics…

Found in Robotics News & Content, with a score of 9.87

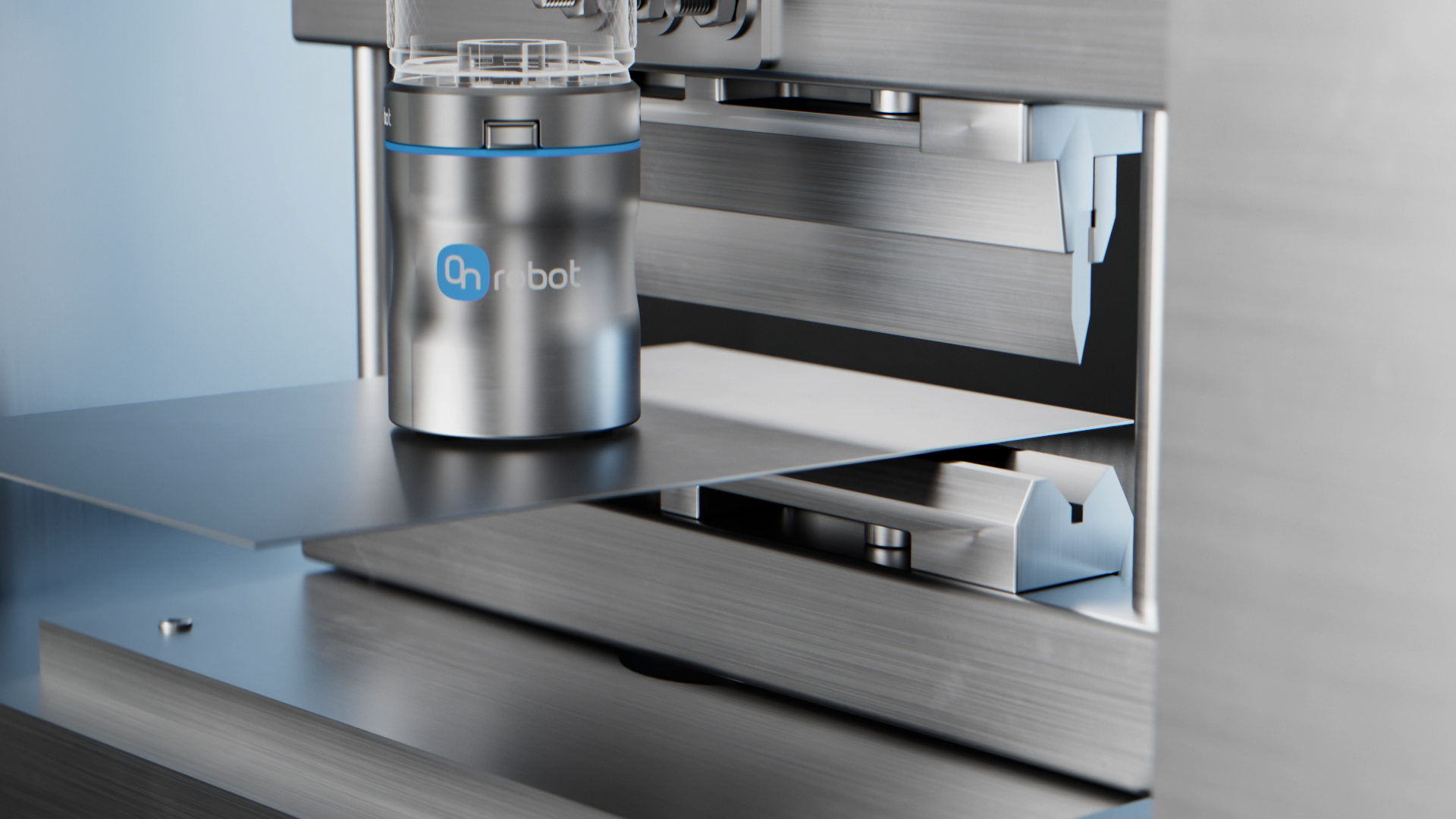

…Gecko gripping technology, force/torque sensors, “2.5D” vision, robotic screwdrivers, sanding kits, and tool changers. The company said it serves applications such as packaging, quality control, and materials handling, as well as machine tending, assembly, and surface finishing. WebLytics uses OEE standard Not only can WebLytics eliminate manual data collection for cobot end users and integrators, but it can also provide actionable insights into how well a collaborative application is performing, claimed OnRobot. The software is also designed to offer live device diagnostics, alerts, and preventive-maintenance measures to minimize costly robot cell downtime, it said. Integrating the globally recognized Overall Equipment…

Found in Robotics News & Content, with a score of 9.87

…of tasks that have previously been manual, such as sanding, polishing, palletizing, and delicate assembly, said the partners. “Merging Flexiv’s robotic expertise with Cardinal’s extensive experience will deliver customers unmatched automation solutions while increasing the productivity, efficiency, flexibility, and competitiveness of businesses within the Great Lake State,” Flexiv said. Dajun Tao, an application engineer at Flexiv (left), meets the Cardinal Machine team. Source: Business Wire Cardinal Machine to integrate Rizon, Moonlight robots “We are excited and look forward to a successful, long-term partnership with Flexiv,” said Brian Pennington, president of Cardinal Machine. “Having Flexiv’s adaptive force-control technology available to us…

Found in Robotics News & Content, with a score of 9.60

…of strategic partnerships at READY Robotics, showed a Yaskawa sanding cell and a visual inspection cell at READY's solutions center in Austin, Texas. Kel Guerin, co-founder and CIO, showed how the Unity game engine works in READY ForgeSim to simulate and program different robots and processes, such as pick-and-place and machine tending operations. This can also help with planning and training, he said. “By unlocking access to robot programming and enabling out-of-the-box control of robotics and hardware, Forge/OS 5 enables hardware OEMs like Schunk to accelerate product development and adoption, and enhance robotic applications far beyond what was possible yesterday,”…

Found in Robotics News & Content, with a score of 9.27

…of a part for deburring or its surface for sanding and grinding, the possibilities are available to all, said the company. Users can add an unlimited number of waypoints to these trajectories, it said. “This functionality offers order of magnitude time savings to users, as the generation of trajectories frees them from dependence on robotic experts,” said Fuzzy Logic. With Fuzzy Studio, the basic specifications of a project can be validated in just a few minutes instead of several weeks, and at a lower cost. Information on the sizing of the robotic cell is displayed for easy decision-making before moving…

Found in Robotics News & Content, with a score of 9.10

…ARM Institute. “Projects have ranged from robots for sewing, sanding and grinding metals, and sorting fish to PCR testing for COVID-19.” “We typically see three types of project teams,” he told Robotics 24/7 during a recent visit to ARM's headquarters in Pittsburgh. “There are the standard vertical teams, involving robotics vendors. Then there are the horizontal ones, such as aerospace manufacturers working on wire harnesses. Finally, there are the non-standard, pre-competitive ones, such as small startups or groups within universities and larger companies.” ARM project call includes new features The ARM Institute's latest project call is different from its predecessors,…

Found in Robotics News & Content, with a score of 8.58

…industrial applications including assembly, inspection, material handling, packaging, palletizing, sanding, and welding. “Our collaborative robots are easy to use and flexible solutions for companies looking to enhance productivity and solve labor issues,” said Eric Potter, general manager of the General Industry and Automotive Segment at FANUC America. “We’ve seen substantial growth in the cobot space, particularly from companies who are new to robotic automation,” he said. “We’re excited to introduce the CRX-25iA cobot with a 30 kg [66.1 lb.] payload capacity, and the CR-35iB cobot with a 50 kg payload capacity. Now, customers can easily handle heavier products with these…

Found in Robotics News & Content, with a score of 8.15

…gripper, the OnRobot Eyes vision system, and screwdriver and sanding tools. It also launched the 2FG7 cleanroom-ready parallel gripper. OnRobot builds MG10 magnetic gripper for smoother handling Today, OnRobot announced the MG10, a new electric magnetic gripper with programmable force features and built-in grip and part-detection features. The company said the MG10 is designed for materials handling, assembly, and machine-tending applications in manufacturing, automotive, and aerospace applications. “Standard magnetic grippers only provide simple on/off functionality,” stated OnRobot. “To adjust the force applied, users have to add rubber ‘feet’ to create space between the magnet and the part. This is a…

Found in Robotics News & Content, with a score of 7.82

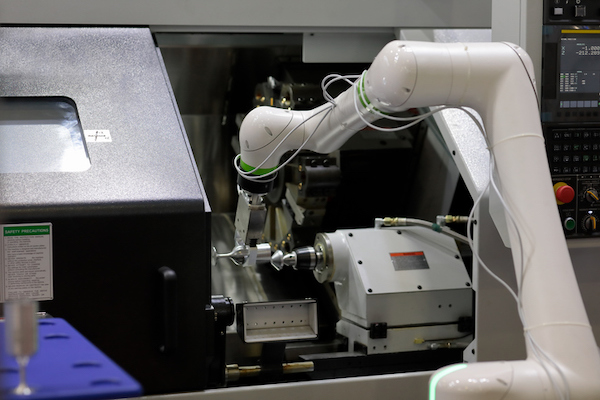

…a welder, a palletizing robot becomes a palletizer, a sanding robot becomes a sander, and so on, working with the respective OEMs in each case. For example, a robot vendor would work directly with a CNC equipment manufacturer to define and develop a custom configuration. This would include the number of degrees of freedom, the payload, reach, mechanical interface, communications, software, etc. Delivering a functional system that is integrated “out of the box” not only automates the machine-tending task, but it also improves total productivity, which is what the end user ultimately values. For reference, the global CNC market was…

Found in Robotics News & Content, with a score of 7.58

…can be deployed on any number of applications, from sanding to assembly to material handling and inspection,” he said. “This allows companies to respond quickly to changing requirements. Furthermore, user-friendly software interfaces have replaced the overly complex interfaces associated with traditional automation.” Collaborative robots start in manufacturing Tomenson Machine Works Inc. is an example of a manufacturer working with collaborative robots. The Chicago-based company looked for a machine-tending system to tend its pin stamper, a very repetitive process in the production of precision hydraulic manifolds. One of the chief challengeswas that the pin stamper had to be able to handle…

Found in Robotics News & Content, with a score of 6.91

…to allow for the handling of delicate objects for sanding and polishing. The robot can be installed at any angle, the company said. Kawasaki Robotics shows automated bin picking At IME West, Kawasaki Robotics displayed two robots. The MC004V, guided by Apera AI’s Vue robotic vision software, demonstrated a random bin-picking application of clear test tubes. Kawasaki said this capability could be useful for pharmaceutical and medical device manufacturing, as well as consumer packaged goods (CPG), injection molding, and plastics. The robot arm meets the healthcare industry’s strict guidelines for accuracy, consistency, and cleanliness, according to Kawasaki. It also has…