Editors’ Picks

Found in Robotics News & Content, with a score of 20.28

The stage is set for the reshoring of U.S. manufacturing to finally gain momentum, and the latest generation of robots represents a key element of the equation. The backdrop against which this shift will unfold reflects a new set of economic realities for the industry. Two elements stand out as drivers of change: the rise in offshore wages and the increase in transportation costs, both of which are causing manufacturers to re-evaluate the benefits of maintaining production operations overseas. “Many companies that established operations outside of the U.S. that may be tied to the offshoring wave of the 1980s and…

Found in Robotics News & Content, with a score of 7.16

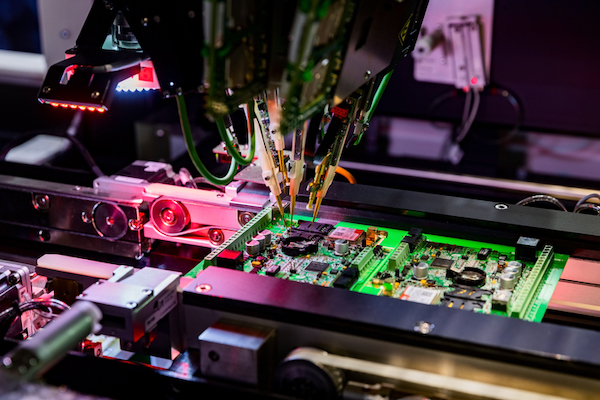

…this shortage relies on maximizing productivity and “near-shoring” or reshoring manufacturing. Robots can partially or fully automate the electronics testing process, providing an extra efficiency boost before and after manufacturing. Some manufacturers are even boosting their efficiency by running fully automated night shifts. Newark, N.J.-based ZAGO applied this exact tactic with robots from Robotiq to meet demand despite staffing shortages. The robots could run for up to 18 hours at a time, mostly unattended. 3. Improved resource utilization Once programmed properly, robots can repeat the same action innumerable times until shutdown or a mechanical failure. As a result, a robot…

Found in Robotics News & Content, with a score of 3.87

…for automation is not going away. Have trends like reshoring of manufacturing increased, and what do they mean for supply chains? Stephen Dryer, FORTNA. Source: LinkedIn Dryer: In the immediate term, customers can't follow a just-in-time model anymore. To rely on the warehouse or DC [distribution center] in a tight time frame means more storage capacity. The micro-fulfillment trend is putting capacity closer to population centers and having a fast way of processing orders to consumers. The shift from brick and mortar has changed dramatically since COVID. I recently bought a couch, and I went to a store to see…

Found in Robotics News & Content, with a score of 18.09

…automation tasks is a very motivating goal.” Povlsen predicts reshoring will help drive automation The UR President predicts an increasing need for automation in the coming years, driven by several different things: a desire to protect employees from dangerous and monotonous tasks; reshoring, where companies move production closer to home in response to an uncertain world; and above all, a shortage of labor which will only get worse in the coming years: “We have a new generation of cobots on the way, with the UR20 being the first model, and our own figures show that we have only reached approximately…

Found in Robotics News & Content, with a score of 8.64

…moving production out of China, and many are considering reshoring,” said Patrick Sobalvarro, president and CEO of Veo Robotics, at The Vision Show last week in Boston. “But total productivity growth hasn't improved. Increased use of automation and fixed capital can introduce inflexibility,” he said. “Bernstein Research noted an inverse relationship between automation levels and labor productivity.” “That's why collaborative robots have seen the success that they have,” Sobalvarro said. “Current safety approaches limit automation productivity.” Veo Robotics said its FreeMove safeguarding system for industrial robots “enables fluid, efficient, and flexible production lines.” The company works with the world’s top…

Found in Robotics News & Content, with a score of 25.65

…labor challenges, North American and European enterprises have considered reshoring or near-shoring operations to build resilience. However, a significant “education gap” exists in the skills needed for reshoring and automation to succeed, according to a global ABB survey. “The world is constantly evolving—businesses are shifting existing structures and adopting new technologies to future-proof their operations for a variety of challenges and uncertainties, with robotic automation playing a key role,” said Sami Atiya, president of ABB Robotics & Discrete Automation. “We need significant investment in continuous education to prepare our existing and future workforce to thrive in an age of robotics…

Found in Robotics News & Content, with a score of 9.44

…firm Kearney recently shared findings from its 2021 index reshoring report and found that the trend will likely continue for the next few years. “Seventy-nine percent of executives surveyed who have manufacturing operations in China have either already moved part of their operations to the U.S. or plans to do in the next three years, and another 15% are evaluating similar moves,” the report noted. Agarwal said he believes part of it has to do with U.S government incentives and grants. Another big reason is that automation is driving costs down and allowing companies to bring operations closer to home,…

Found in Robotics News & Content, with a score of 5.62

…are looking to improve productivity and increase efficiency. In addition, robotics is key to national competitiveness. With onshoring and reshoring of manufacturing back to the U.S., robots can help address supply chain issues. We want to build robots that are indispensable. Developers have to build robots that improve the ways people live so it's hard for them to imagine doing their jobs without robots. The promise of technology has largely been about the idea of time. There were thinkers who predicted a four-hour workweek by the turn of the century. No other technology can deliver that besides automation as a…

Found in Robotics News & Content, with a score of 9.81

…to other industries.” Other industries to benefit from cobots, reshoring “Healthcare, pharmaceuticals, and e-commerce demand went up because consumers couldn't go out like normal [during the COVID-19 pandemic], said Finazzo. “We're seeing new customer activity at record highs.” “In addition, collaborative robots subsidize labor rather than replace it,” he said. “You can take one skilled person, add three robots, and still come out ahead. When cobots came out, there were a lot of false starts around safety, which depends on the end-of-arm [tooling and payloads]. But their ease of programming has been tremendous for processes like welding and assembly, where…

Found in Robotics News & Content, with a score of 5.05

…all jobs lost during the pandemic. Some companies are reshoring manufacturing activities, reducing reliance on overseas partnerships. Manufacturers should also accept new ideas for securing and strengthening supply chains to avoid future challenges, should a similar pandemic or political tension occur. Enhanced factory digitization Digitization increases autonomy and efficiency on the factory floor. Industry 4.0 is all about the smart factory. Companies are focusing on on enhancing equipment connectivity through IoT sensors, customizing production and predicting market trends in advance. The use of robots for diverse production activities enhances modular production, warehouse management, quality inspection, and prototyping initiatives. The digital…

Found in Robotics News & Content, with a score of 19.29

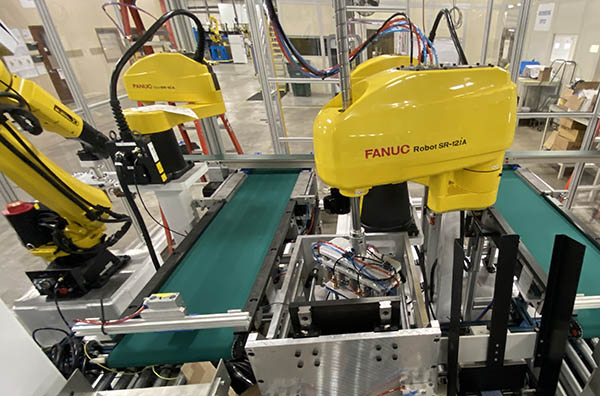

…and resilience in production is driving the interest in reshoring/nearshoring and, as a result, the demand for more automation. He underscored the role of robotics in facilitating reshoring or nearshoring efforts, addressing supply chain concerns, and maintaining global competitiveness for U.S. businesses. Once confined to the automotive industry, automation and robotics have significantly expanded across multiple industries and sectors across the United States, including logistics, food and beverage, retail, and healthcare. American companies are increasingly turning to automation and robotics driven by the need for greater flexibility in operations, widespread labor shortages, and an aging workforce. Source: ABB 43% of…

Found in Robotics News & Content, with a score of 6.63

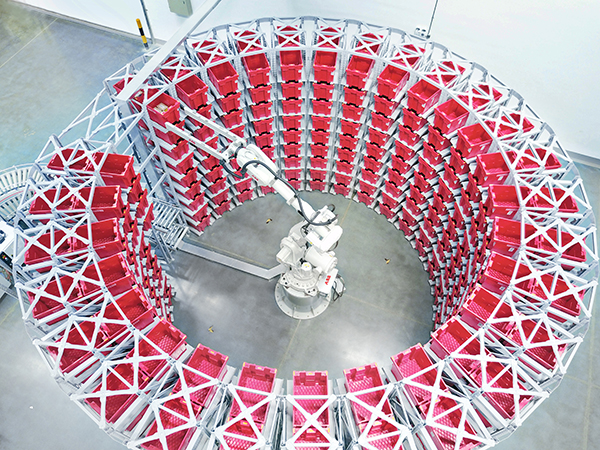

…to satisfy their customer’s most pressing needs, especially as reshoring becomes a prominent means to address ongoing supply chain backlogs,” he added. ABB to show AMRs from ASTI acquisition At Booth 1832, ABB will provide full-motion demonstrations of automated guided vehicles (AGVs) and autonomous mobile robots (AMRs) it acquired with ASTI Mobile Robotics last year. The Auburn Hills, Mich.-based company claimed that it is the only vendor “to offer a complete portfolio of flexible automation.” The exhibit will include two EBOT 350 AMRs for goods-to-person processes in e-commerce, logistics, automotive, or manufacturing sectors. It can also perform hundreds of applications…