Editors’ Picks

Found in Robotics News & Content, with a score of 0.50

…and elevators and can work with other AMRs and AGVs. The launch of uLink marks United Robotics Group’s expansion of robotics offerings in logistics and warehouse management and industrial production. The robot will be deployed in retail and logistics settings including department stores, supermarkets, warehouses and fulfillment centers, factories and manufacturing settings as well as airports and healthcare facilities. The uLink is connected to an online dashboard that facilitates workflow management and decision making between front and back of house teams. It has a battery life of up to 14 hours of operations on one charge and features a smart,…

Found in Robotics News & Content, with a score of 0.50

…The company's systems include goods-to-person technology, autonomous guided vehicles (AGVs) for material handling, intelligent information systems, robotic picking systems, and tote-to-pallet automation. PANGQI said it enables conveyor lines and large warehouses to be intelligent, providing customized services for customers. P800 goods-to-person picking robots transport goods. Source: Geek+ Geek+ provides mobile platforms The joint project features multi-floor robot collaboration, as well as fully integrated digital operations for the first time, setting a new benchmark in terms of scale and complexity, claimed the trio. More than 100 Geek+ robots are handling nearly 30 different LED production operations over 10 floors and an…

Found in Robotics News & Content, with a score of 0.49

…exploding. By 2026, The market for automated guided vehicles (AGVs) and AMRs is expected to reach $13.2 billion, with a growth rate of about 35%, according to Research and Markets. In the forklift market, automated vehicles are expected to rise from 1% to 33% in 2030, according to ABI Research. Similarly, Fortune Business Insights predicted that AMR demand will experience a compound annual growth rate (CAGR) of 23.7% between 2021 and 2028. Despite growing demand, logistics vehicle manufacturers and new players find it hard to develop AMRs and automated logistics vehicles that meet customer expectations. There has been a lack…

Found in Robotics News & Content, with a score of 0.49

…depalletizing. The survey also asked about automated guided vehicles (AGVs), a more established category in which the vehicles typically use guidance infrastructure like tape to navigate. AGV interest also climbed, from 7% using in 2018 to 11% in 2019, and 18% evaluating vs. 14% last year. In another bright spot for AGVs, their applications range is expanding into areas beyond materials transport. For instance, this year 29% are using or evaluating AGVs for bin picking, up from just 17% last year. When it comes to devices and mobile solutions, there were some mixed results. Overall, those using or with plans…

Found in Robotics News & Content, with a score of 0.47

…was the first AMR vendor to support the well-known AGV standard, VDA5050, empowering customers to manage dissimilar types of material handling solutions from a third-party master controller interface. New pallet types: OTTO Lifter now supports BulkPak 4845 HDMP series bins, enabling customers to move more pallets of their choice. Since its inception, OTTO Motors said it has helped customers achieve throughput improvements as high as 600% and return on investment in as little as 11 months in different industry verticals. OTTO Motors noted the launch of OTTO 600 and its new software enables it to help manufacturers automate a larger…

Found in Robotics News & Content, with a score of 0.47

…it,” says Saenz, who also sees automated guided vehicles (AGVs) as a good “current” example of robotics on the dock, where they’ll play a more prominent role in the near future. Companies like Fetch Robotics, for example, make autonomous mobile robots that can handle “pretty good-sized payloads,” according to Santagate, and that help shippers move pallets (i.e., into the warehouse, or cross-dock to another vehicle) once they’re unloaded from the truck itself. “Shippers can already use AGVs to load and unload full, palletized truckloads or less-than-truckloads at this point,” Saenz adds, “so that’s the real deal.” Managing complexities, overcoming challenges…

Found in Robotics News & Content, with a score of 0.46

…use of what Gartner calls smart automated guided vehicles [AGVs], that are also known as autonomous mobile robots, within DCs,” says Klappich. “They’re going to have a dramatic effect on how you can operate a warehouse, and how you design and build warehouses.” Mobile robotics, contends Klappich, are more flexible than traditional automated materials handling systems that require extensive fixed infrastructure. Mobile robotics/smart AGVs that can carry or pull inventory to workstations—or function as smart, driverless lift trucks—would alleviate the labor needs at the DC level, and allow for DC automation that’s quicker to install and reconfigure. “There has always…

Found in Robotics News & Content, with a score of 0.46

…36 of those spools onto an automatic guided vehicle (AGV). The AGV can then move to another area of the warehouse or plant to offload the items. “This is just one example of how we’re already seeing robotic arms integrated with vehicles,” says Longacre, “and being used to manage stationary/repetitive tasks.” Don Heelis, sales manager at Cimcorp, is also bullish on the robot’s ability to break through the barriers and start handling more distribution functions. He says Cimcorp has completed a number of installations with autonomous robots in a fleet environment, which is yet another step in the direction of…

Found in Robotics News & Content, with a score of 0.45

…floor plan changes. More flexible than automated guided vehicles (AGVs), AMRs are suitable for scaling and dynamic environments. 6. Industrial robots have evolved from machine to machine Prior to the advent of AI and modern robotics, the standard in manufacturing was called machine-to-machine or M2M. This basically had to do with either Ethernet connections or other types of wired or wireless connections that allowed individual machines to talk to one another and collaborate on tasks. Modern AMRs go beyond that by untethering machinery or equipment from one static workspace. The above use cases show how mobile robots can take on…

Found in Robotics News & Content, with a score of 0.45

…to delivering them to end customers. Automated guided vehicles (AGVs) are widely used for transportation in limited spaces. Robots and cobots can be introduced to many parts of the supply chain for faster execution of tasks. The use of automation can reduce dependence on employees to perform various tasks. With decreasing costs and improving technology, AGVs, autonomous mobile robots (AMRs), and cobots can increasingly help improve supply chain operations. In a recent Zebra Technologies survey, 62% of industry participants reported that human error from manual process management is the top reason for inventory fulfillment problems. This includes picking errors, errors…

Found in Robotics News & Content, with a score of 0.45

…manufacturers will be investing in robotics, autonomous guided vehicles (AGVs) and associated systems within their warehousing operations to drive automation into their fulfillment processes. ● By 2018, proliferation of advanced, purpose-built, analytic applications aligned to the Internet of Things (IoT) will result in 15% productivity improvements for manufacturing supply chains. ● By 2020, 50% of the operational jobs in the supply chain will have evolved into “knowledge” roles required to support new technologies like cognitive computing and modern robotics. IDC also offered the following observations: ● Customer engagement and customer service are woven into a number of manufacturer’s priorities and…

Found in Robotics News & Content, with a score of 0.45

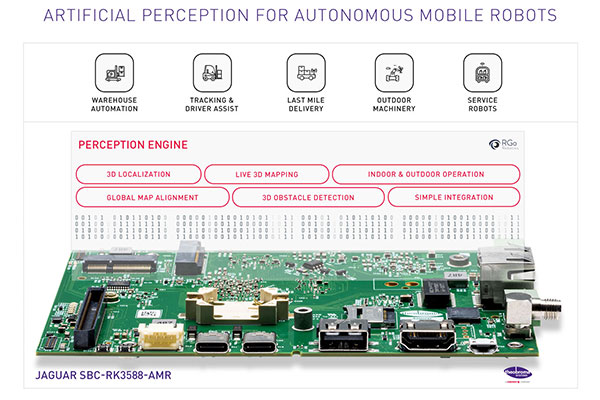

…as autonomous mobile robots (AMRs) and automated guided vehicles (AGVs), as well as professional service robots such as those used in transportation, hospitality and agriculture. “The joint solution offers a perfect balance between performance and cost, enabling manufacturers of robots and industrial automation machines to rapidly open up new business areas with innovative products,” said Stefan Roth, managing director at Theobroma Systems. Machine vision provider RGo Robotics has teamed up with Capra Robotics to develop autonomous mobile robots capable of bridging the gap between controlled warehouse environments and the unstructured outside world. Photo: Donald Halsing / PEERLESS MEDIA Intel processors…