Editors’ Picks

Found in Robotics News & Content, with a score of 20.53

…with Pellet and Filament Extrusion capabilities at this year’s Additive Manufacturing Users Group conference. To demonstrate printing of production parts using materials on the Atlas 3D printer platform, Titan is partnering with three chemical companies serving the additive manufacturing industry: Arkema Inc., DuPont and NatureWorks. Titan will be printing with three materials on the Atlas 3D Printer during the 2019 AMUG Expo, March 31 and April 1. AMUG Expo attendees can view high-speed printing of these materials from Arkema, DuPont and NatureWorks. Representatives from Titan and the material companies will be at the Titan booth to discuss printer capabilities, material…

Found in Robotics News & Content, with a score of 20.45

…NIST (National Institute of Standards and Technology) video, Rethinking Manufacturing, that aired on Monday, August 19 at 4:30 p.m. at YBI’s “Tech Block Building Five.” The Rethinking Manufacturing video features two Youngstown natives and promising engineers, America Makes Project Engineer Ashley Totin and JuggerBot 3D co-founder and president Zac Divencenzo, and their journey to find their career paths in the wake of the economic decline of their hometown. Once a thriving steel town, the collapse of the industry in the 1970s hit Youngstown particularly hard. During the following decades, Youngstown experienced harsh economic times due to significant job losses that…

Found in Robotics News & Content, with a score of 20.26

America Makes and Air Force Research Laboratory, Materials & Manufacturing Directorate Structural Materials, Metals Branch (AFRL/RXCM), announce an additive manufacturing (AM) Modeling Challenge Series, comprised of four individual Challenges, with $150K to be divided among awardees. The AFRL AM Modeling Challenge Series represents another approach America Makes, the National Additive Manufacturing Innovation Institute, and AFRL are taking to advance the AM industry. By challenging the brightest minds from industry and academia, the AFRL AM Modeling Challenge Series will be influential in the development of solutions focused on validating/improving the accuracy of model predictions for metal AM, according to America Makes.…

Found in Robotics News & Content, with a score of 20.24

…says sintering is a critical step in powder metallurgy-based manufacturing processes, including binder jetting. It involves heating parts to near melting to impart strength and integrity, and typically causes parts to shrink by as much as 20% from their original printed or molded dimensions. During the process, improperly supported parts also face significant risk of deformation, resulting in parts that emerge from the furnace cracked, distorted or requiring costly post-processing to achieve dimensional accuracy. Traditionally the solution for shrinkage and distortion was to rely on the experience of industry veterans who, based on repeated trial and error, combine adjustments to…

Found in Robotics News & Content, with a score of 20.19

…for Multi-Laser Machines” awarded through the National Center for Manufacturing Sciences’ (NCMS) Advanced Manufacturing, Materials, and Processes (AMMP) program. Working in conjunction with Raytheon Technologies, the Penn State Applied Research Lab, Johns Hopkins University and Identify3D, the goal is to optimize a component relative to an Army modernization product to maximize cooling and improve overall system performance. Using additive manufacturing (AM) to address this need is a novel approach to the project that covers the entire part lifecycle including determining performance requirements, topologically optimizing the design, manufacturing the part with attention to process monitoring for quality control, component performance validation,…

Found in Robotics News & Content, with a score of 20.07

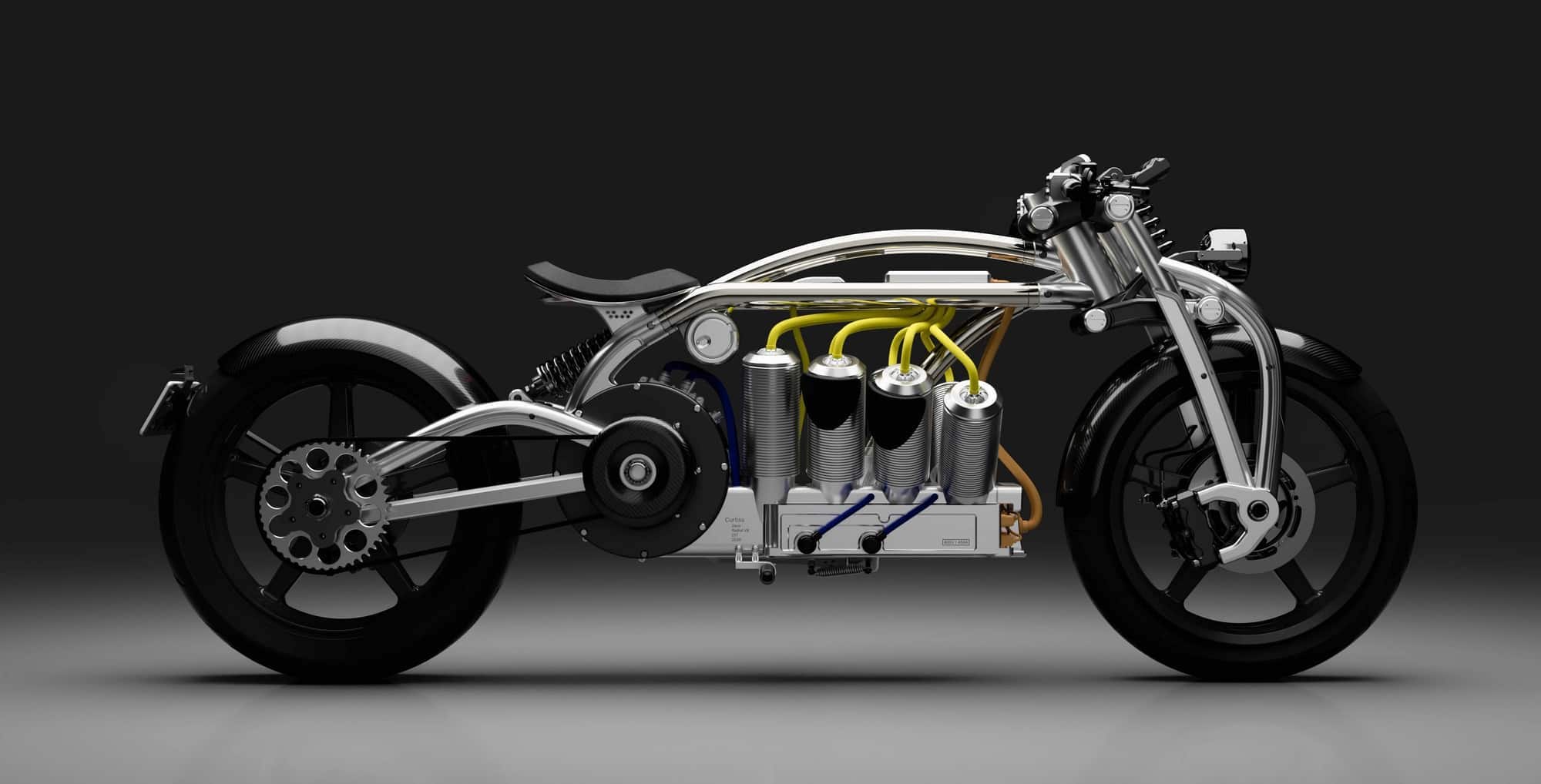

…Curtiss turned to Fast Radius, a provider of hybrid manufacturing services, to get the unique bike into production quickly so it could make its planned launch date. “We had three weeks to make it to the show—there was no chance a traditional approach to manufacturing would make that possible,” says Matt Chambers, CEO of Curtiss Motorcycles. Working with Fast Radius, the partners came up with a hybrid manufacturing approach that leveraged CNC milling, hot tube bending and additive manufacturing. Instead of trying to force a single manufacturing process for Zeus, the team leveraged the strengths of the different methods when…

Found in Robotics News & Content, with a score of 19.97

…check out the latest technologies and network at the Additive Manufacturing Users Group (AMUG) 2019 conference. Like the 3D printing/additive manufacturing sector itself, the AMUG conference continues to grow. Now in its 31st year, the volunteer team of conference organizers say this was the largest conference yet. AMUG Advisor Todd Grimm enters the Twilight Zone at AMUG 2019. “You are in an alternate reality right now, at this minute, and you're poised to be in a very significantly different alternate reality,” Todd Grimm, president of T.A. Grimm & Associates, told the AMUG audience after doing his best Rod Sterling Twilight…

Found in Robotics News & Content, with a score of 19.94

Nano Dimension Ltd. has introduced its DragonFly Lights-Out Digital Manufacturing (LDM) printing technology, a comprehensive additive manufacturing platform for round-the-clock 3D printing of electronic circuitry. The DragonFly LDM system is designed for Industry 4.0 and manufacturing for the Internet of Things and is the extension of the successful DragonFly Pro precision system, which is dedicated to printing electronic components such as multilayer printed circuit boards (PCBs), antennas, capacitors and sensors. The DragonFly LDM is already available through Nano Dimension’s global sales channel. In Germany, the launch of the DragonFly LDM was already initiated by Nano Dimension’s reseller, Phytec New Dimension.…

Found in Robotics News & Content, with a score of 19.87

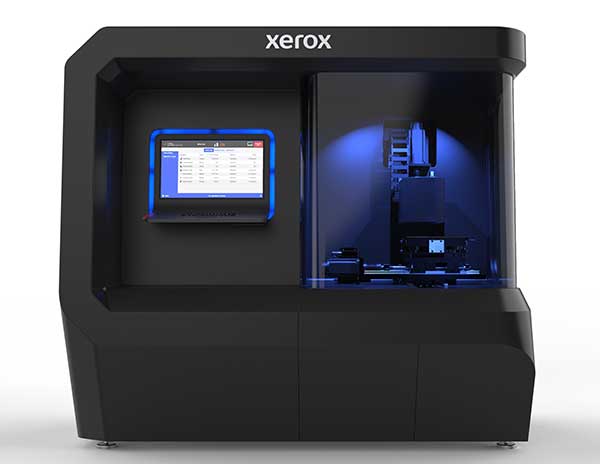

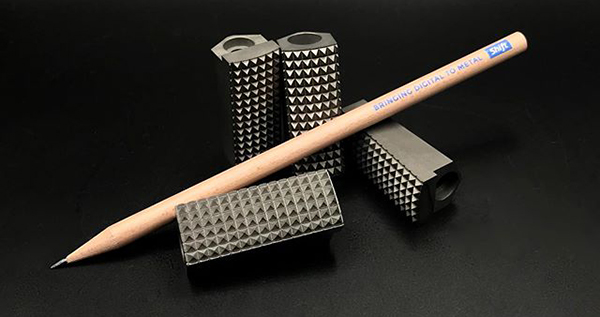

…School (NPS) announces a strategic collaboration focused on advancing additive manufacturing research, specifically 3D printing, which has the potential to transform the way the military supplies its forward-deployed forces, organizations note. As part of a Collaborative Research and Development Agreement (CRADA), NPS was the first to receive an installation of the Xerox ElemX Liquid Metal Printer on the university campus in December. The Xerox solution will provide NPS faculty and students with hands-on exploration of new ways the technology can deliver on-demand 3D printing of metal parts and equipment. “The military supply chain is among the most complex in the…

Found in Robotics News & Content, with a score of 19.83

…production, rail operators will be best positioned to leverage additive manufacturing for the production of spare parts on demand that meet strict government certification requirements for smoke, fire and toxicity. Both materials have passed the European Union’s Rail Standard, EN45545-2. The Stratasys ecosystem of customers and partners benefiting from the Rail Industry Solution currently includes Angel Trains, Bombardier Transportation, Chiltern Railways, DB ESG and Siemens Mobility. Stratasys’ additive manufacturing consultancy, Blueprint, has estimated that for one major U.S. commuter rail service, every day a train set is out of service costs €18,000, and often a single part that would ordinarily…

Found in Robotics News & Content, with a score of 19.81

…on PA6-carbon fiber composites extend Impossible Objects’ composite based additive manufacturing process (CBAM) to a range of industrial applications. “It’s been exciting to see how our customers are putting our approach to work to create high-performance parts for everything from aircraft and cars to lightweight athletic gear,” says Impossible Objects founder and chairman Bob Swartz. “We’re continuing to bring machines, materials and expertise to the market to transform the entire manufacturing process, from prototyping through to high-volume production.” CBAM-2 Speeds Production of 3D Parts at Scale The new CBAM-2 3D printing system, being shown at RAPID + TCT for the…

Found in Robotics News & Content, with a score of 19.74

Xometry, a large marketplace for on-demand manufacturing, has acquired Munich, Germany-based Shift, another large on-demand manufacturing marketplace, which is based in Europe. Through the acquisition, Xometry will accelerate its international expansion into 12 new countries, leveraging a worldwide network of over 4,000 manufacturers. “Global expansion is a key step for us,” says Xometry CEO Randy Altschuler. “Many of our customers, like BMW and Bosch, have a global presence and we can serve more of their needs with a global network. Our AI-driven algorithms and intelligent sourcing platform give us a competitive advantage as we expand across new geographies and manufacturing…