Editors’ Picks

Found in Robotics News & Content, with a score of 4.36

…gained in areas such as operations, planning, labor, and inventory. Why did Dematic choose Google Cloud? “A few things led us toward Google—their vision and strategy aligned almost perfectly with ours,” replied Chris Shaver, global vice president for product management at Dematic. “Secondarily, a significant portion of our customer base sees Google as a strategic partner.” “Google has advanced AI/ML capabilities, but at the end of the day, it comes back to having a partner that wants to impact society and the world in the same way we do,” he told Robotics 24/7. “Dematic brings 200 years of warehouse automation…

Found in Robotics News & Content, with a score of 17.88

…a three-year partnership with L’Oréal to conduct the annual inventory of the cosmetics company's distribution center in Northern France. Delta Drone will be deploying its COUNTBOT system at the facility, which consists of a robot, 14 high-resolution cameras, a mast that can reach 10 m (32 ft.), and a drone. The company said it has developed and tested the system in partnership with logistics group GEODIS and “guarantees the protection of goods and people.” “A major ally in warehouse quality managment, COUNTBOT combines ground robot and aerial drone technologies to carry out fast, accurate and automated inventories,” reads an excerpt…

Found in Robotics News & Content, with a score of 2.93

…that its comprehensive offering does the following: Intelligently optimizes inventory placement through inVia Logic, enabling random access to a wide variety of SKUs being delivered directly to consumers Manages orders to leverage batching and pick-path efficiency to speed the retrieval of goods by inVia Picker robots Dynamically allocates labor resources based on productivity data to maximize throughput and minimize idle time In addition, workers used inVia PickMate productivity tools on existing handheld devices to receive intuitive, step-by-step instructions to complete fulfillment tasks. Eliminating the need for additional training time, PickMate boosted both efficiency and accuracy rates immediately, the company claimed.…

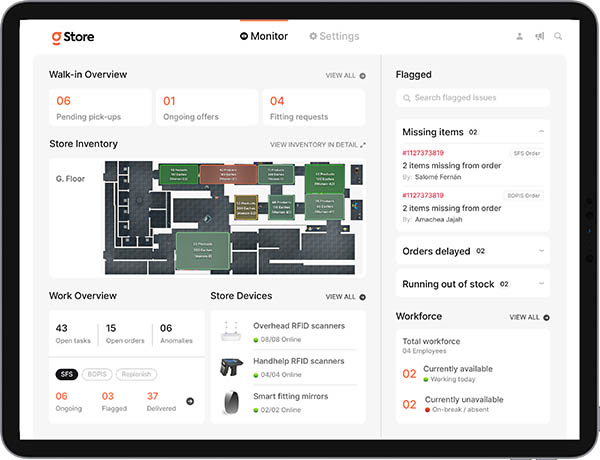

Found in Robotics News & Content, with a score of 3.28

…percent of companies are currently looking to improve their inventory control and lower costs, the company said. Lakestar leads the round, with participation from Maersk Growth, Kindred Capital, and Capnamic. “More than 80% of warehouses have no automation at all,” said Lakestar Partner Christoph Schuh. “With warehouses expected to grow by 50% by 2025 and labor shortages of over 30%, automation clearly holds the key to ensuring logistics operations are as optimized as possible. “Logistics is an industry that always faced margin pressures and little means to invest into a digital infrastructure. BotsAndUs real-time data capture abilities create this infrastructure…

Found in Robotics News & Content, with a score of 4.78

…said its systems can meet challenges including high SKU inventories, complex packaging, and fragile items. The San Francisco-based company said its machine vision and control software is designed for goods-to-robot (G2R) use cases in warehouses. At Zenni's fulfillment center, OSARO's pick-and-place robot will process online orders. Zenni has a team of workers capable of handling 10 orders per minute, noted the companies. In addition, the partners said that robots can mitigate the staff turnover and shortages that are plaguing the fast-growing e-commerce industry. OSARO's picking robot works with automated bagging machines to accurately fulfill eyeglass orders. Source: OSARO OSARO describes…

Found in Robotics News & Content, with a score of 2.61

…potential use cases, said Nielsen. They include cleaning robots, inventory scanning robots, and assistive-pick AMRs. It is inevitable customers will have AMRs from multiple vendors, with a resulting need for a layer of “interfleet management” software. Nielsen said that MIR isn’t developing this capability itself, adding that some of its customers are looking at using software from Amazon Web Services (AWS) called RoboRunner for this purpose. Other Automate exhibits of interest SVT Robotics had a sizeable booth at Automate. The vendor, which offers a software platform to speed and simplify integration of robotics solutions with host systems like a warehouse…

Found in Robotics News & Content, with a score of 2.54

…for people to travel across a facility to retrieve inventory and deliver it to the packing station. In addition, inVia Pickers are mobile, unlike traditional shuttle systems, and they can be moved to work in different zones or in other locations. The company said this eliminates the need for re-engineering facilities, allowing inVia to adapt to different environments. The Frost & Sullivan Best Practices Awards recognize companies across the globe for demonstrating outstanding achievement and superior performance in leadership, technological innovation, customer service, and strategic product development. inVia said it was awarded based on its commitment to innovation, creativity, and…

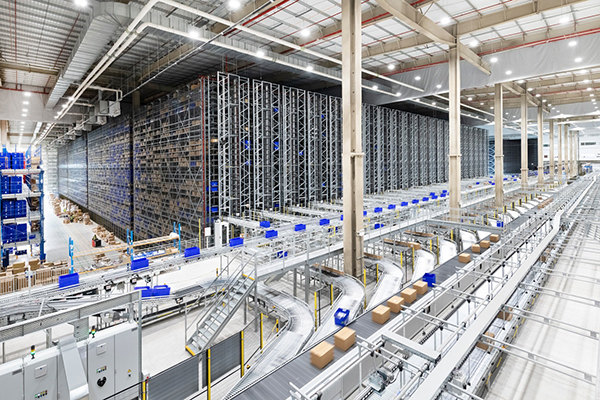

Found in Robotics News & Content, with a score of 6.76

…biggest challenges of today’s complex supply chain, such as inventory agility, transportation cost, and labor availability.” “Modernizing the warehouse allows consumers to get what they need faster and creates benefits for everyone, including workers, customers, and their local communities,” he added. Symbotic System designed for numerous SKUs Symbotic said it is “reimagining the supply chain with its end-to-end, AI-powered robotic and software platform.” The Wilmington, Mass.-based company has built a fleet of autonomous mobile robots (AMRs) powered by machine learning. Combined with a high-density physical structure, the system can improve efficiency, accuracy, and agility while reducing costs, claimed Symbotic. The…

Found in Robotics News & Content, with a score of 3.38

…around autonomously in tall, narrow aisles, with frequently changing inventory and very few fixed physical features to guide them. San Francisco-based Ouster said it is combining its high-resolution lidar data with the MOV.AI Robotics Engine Platform, advanced simultaneous localization and mapping (SLAM) navigation, obstacle avoidance, and risk-avoidance systems. The companies said they will help AMRs operate efficiently and continuously in dynamic environments, environments with little static information, and environments with repeated structures. “MOV.AI's mission is to speed up robot development and to provide AMR manufacturers and integrators with everything they need to develop and operate great robots,” said Motti Kushnir,…

Found in Robotics News & Content, with a score of 5.96

…and grow the adoption of its robotics hardware and inventory optimization software. “Our fulfillment platform revolutionizes how the largest and best-known retail brands in the world, such as Walmart and H&M, fulfill their promises to customers, employees, and shareholders,” stated Samay Kohli, co-founder and CEO of GreyOrange. “As e-commerce sales soar, brands face a stark reality: embrace automation or cede customers to the competition.” “We orchestrate fulfillment and optimize inventory in a complex global supply chain environment for more companies that ship millions of items each day than any other player in the market outside of Amazon,” he said. “This…

Found in Robotics News & Content, with a score of 2.70

…Respondents to the survey said they're expected to maintain inventory accuracy and visibilty while also delivering orders faster than ever. They said their shipping volumes have increased more than 20% over the past two years, and rising transportation costs have affected 40% of warehouse operators. Between now and 2025, over 80% of operators expect to increase the number of stock-keeping units (SKUs) they carry and the volume of shipped items. This will lead to expanded returns, value-added services, and physical footprints, said Zebra. While 61% of warehouse operators also want to increase headcount within the next year, recruitment and retention…

Found in Robotics News & Content, with a score of 5.07

…robots (AMRs) automate the picking process by bringing the inventory shelves to the warehouse operator at the picking station. The system reduces the time spent finding and moving goods around manually and improves not only picking accuracy but also employee productivity and comfort. Empowered by artificial intelligence, inventory shelves are arranged according to demand in real time, according to Geek+. The most in-demand items are close to the operator to ensure a fast and efficient picking process, it added. Geek+ claimed that its products offer valuable flexibility to companies navigating the rapid changes inherent to e-commerce. The sudden rises in…