Editors’ Picks

Found in Robotics News & Content, with a score of 4.58

…can be used for developing solutions for perception, navigation, manipulation and control in robotics systems. Developers can train and test robotics software using realistic virtual simulation environments. MathWorks added more deep learning enhancements to its latest releases of MATLAB and Simulink for designing and implementing deep neural networks and AI development. The Deep Learning Toolbox can be used to train deep learning networks for computer vision, signal processing and other applications. A Deep Network Designer app uses a drag-and-drop interface to help engineers build, visualize and edit deep learning networks. “If an engineer or data scientist wants to detect specific…

Found in Robotics News & Content, with a score of 15.80

…advanced projects in computer vision, embedded systems and autonomous manipulation, they were drawn into the industry by a customer who asked if they could develop a robot that picked items from warehouse shelving. Like many companies, this customer faced high labor turnover and hiring issues. The result was the first autonomous mobile manipulation robot worker that performed fundamental picking tasks in human environments. “We’re expanding what is possible to accomplish with autonomous robots,” said Galluzzo, CTO. “There is a great deal of buzz around autonomous cars, but we see shorter term opportunities to put autonomous robots to work performing tasks…

Found in Robotics News & Content, with a score of 9.74

…two organizations are collaborating on the deployment of mobile manipulation solutions, or the type of robots that can both pick up and transport goods. “This is the goal that the entire logistics industry is working toward, fully flexible distribution solutions and models – the kind of capability that allows organizations to be responsive to the accelerated pace of change,” said Reed, “To achieve this vision, we’re having open dialogues about customers’ needs, a roadmap for the future, and where those two intersect.” “In the warehouse, fully-automated applications will be the key to sustainability and competitiveness in the new marketplace,” Stikes…

Found in Robotics News & Content, with a score of 9.69

…station pilot study, including the computer vision, sensors, robotic manipulation of the fueling nozzle, and remote controlling mechanisms. “Today, the technology can retrofit existing GenFuel sites supporting the more than 20,000 GenDrive fuel cells in the field,” said Dustan Skidmore, Vice President of Engineering for Plug Power. “In the future, the technology can be used in on-road fleet vehicles, autonomous guided vehicles (AGVs), and self-driving passenger cars.” “The Plug Power partnership is a great success story for RPI CATS, as we look to develop projects that will become an important part of the business’ long-term strategy,” said Stephen Rock, PhD,…

Found in Robotics News & Content, with a score of 8.27

…a vice president with IAM Robotics, calls a “mobile manipulation robot” approach. “We have a mobile platform that travels autonomously into the warehouse storage, finds the inventory locations, individually identifies objects, and picks the objects.” IAM’s units have been deployed at companies including Rochester Drug Cooperative. A recent twist on IAM Robotics’ technology is the Swift Picking Module, which functions like a flexible automated storage and retrieval system (AS/RS), but rather than being an enclosed storage infrastructure with an enclosed crane or other movement mechanism, it uses IAM’s mobile manipulation robots and an open shelf environment. The major advantage of…

Found in Robotics News & Content, with a score of 9.98

…and method for piece-picking or put-away with a mobile manipulation robot. The patent focuses on the underlying system and methods for the Swift Solution Suite, which powers IAM Robotics’ world’s-first mobile picking robot. This technology enables their robots to autonomously navigate human-friendly environments, identify the location of objects, and pick individual items or bins. It has already been deployed at a Rochester Drug Cooperative facility in Rochester, New York. This comes at a time when the US is facing a nationwide labor shortage of workers to fill material handling jobs. Logistics and manufacturing companies are also facing increasing pressures on…

Found in Robotics News & Content, with a score of 9.57

…solutions combining object recognition, pose recognition, grasp planning, compliant manipulation, motion planning, task planning, task execution, and error detection and recovery to successfully pick and stow unique items. Teams were judged based on how many items were successfully picked and stowed by their robots in a fixed amount of time. A total of $270,000 in prizes were awarded to contestants throughout the four-day competition. “This year we made some changes to the challenge to make it even more difficult and to encourage broader participation from multiple robotics fields – and the response was exciting,” said Joey Durham, contest chairperson and…

Found in Robotics News & Content, with a score of 6.63

…can start operating. Robotic Materials—Integrated tactile sensing and robotic manipulation. The patent-pending sensors and control system is the first and only effective tactile sensing solution designed to improve and expand collaborative robot applications. The combination of proximity, contact, and force sensing enables robots to accurately identify, grasp, and manipulate previously unknown parts, such as changing CNC parts in a manufacturing environment without expensive reprogramming. SAKE Robotics—Robotic grippers that are inexpensive, durable, light weight and very capable for use on service robotics. The core technologies include a tendon-based architecture that is low wear, super strong, and very scalable. Vention—A machine-design platform,…

Found in Robotics News & Content, with a score of 7.92

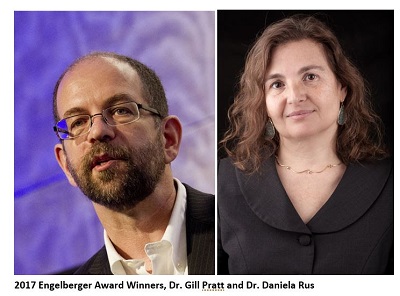

…fundamental programs in neuromorphic computing and robotic mobility and manipulation, and initiated and led the international DARPA Robotics Challenge. The Challenge led to significant innovation in controlling robots from a distance despite degraded communications. Dr. Pratt currently serves as the Chief Executive Officer of the Toyota Research Institute (TRI), a research and development enterprise endeavoring to create a car that is incapable of causing a crash. It also seeks to provide expanded access to cars for those who otherwise cannot drive, including seniors and those with special needs, and to develop home robots for aging society. Few people have had…

Found in Robotics News & Content, with a score of 24.24

…partner with Yaskawa to develop the future of mobile manipulation and collaborative robots,” said Matt Rendall, chief executive officer at Clearpath. “Combining our cutting-edge self-driving industrial vehicles with Yaskawa’s industry-leading robot arms will enable a new category of automation for machine tending.” The solution will provide natural feature navigation, so there is no need to add fiducials or reflectors to the operating environment. The system is reconfigurable to accommodate changing operational preferences and/or changing facility infrastructure. It is also easily redeployable between various processes due to increase or decrease in production volume. This solution will be introduced at AUTOMATICA 2016…

Found in Robotics News & Content, with a score of 15.33

…perspective on emerging technologies like self-driving vehicles and mobile manipulation, as well as start-ups and venture capital.” The Director At-Large positions were announced at RIA’s Annual General Meeting on February 2, 2016 in Orlando, Fla. The RIA board is comprised of 22 directors who meet four times per year to plan the strategic direction of the association. “We’re thrilled to welcome Matt Rendall to the RIA Board of Directors,” said Jeff Burnstein, president of RIA. “Matt has the experience, insight and expertise to represent the mobile robotics community on our board.” Robotic Industries Association drives innovation, growth, and safety in…

Found in Robotics News & Content, with a score of 4.49

…piece picking, humans have the advantage of highly dexterous manipulation, versatile product identification and intuitive decision-making. Robots offer consistency and predictability, but they will need greater speed and flexibility to keep up with the inconsistent and unpredictable world of e-commerce fulfillment. Researchers, solution providers and end-users are still in the very early stages of identifying the opportunities, developing highly customized solutions and quantifying the results. However, because the optimal piece-picking robotic system will depend on efficient and connected processes, many operations will build comfortable homes for robots long before they are ready to move in. “In the past, there were…