Editors’ Picks

Found in Robotics News & Content, with a score of 19.20

…manufacturing costs and improve supply chain efficiency. Automotive Spot Welding “Complex production parts are required to weld tight spots of the car body,” Mark adds. “They cost thousands of dollars to make and can have months-long lead times. But Markforged is changing all of that by enabling manufacturers to produce parts in-house so they get them faster and for significantly lower costs. With our 3D printed parts, automotive manufacturers can print the parts they need on demand instead of holding significant inventory and will be able to design new kinds of welding shanks that were never before possible.” Hundreds of…

Found in Robotics News & Content, with a score of 9.58

…its Hiroshima plant to deliver Mazda door panels to welding cells as part of a mission-critical process. The OTTO materials handling platform allowed HIROTEC to easily reconfigure its process to improve material movement efficiency and increase throughput. By installing the three OTTO self-driving vehicles, HIROTEC was able to eliminate the need for eight legacy Autonomous Guided Vehicles (AGVs). This is the second deployment of OTTOs within HIROTEC, they were first deployed at HIROTEC AMERICAS in 2017 to automate spare parts production. “Altech has a proud history of providing high-quality technology products and services to our customers,” said Hidehiko Suyama, executive…

Found in Robotics News & Content, with a score of 16.06

…simulation applications that incoperate its technology, among them a welding simulator and an automotive body painting simulator from Lincoln Electrics and Honda. Aimed at providing industrial skills training, the simulation systems incorporate not just immersive visuals but also physical props—replicas of weld guns and spray paint guns used in real operations. The appeal for the use of ARVR training comes from the expected cost savings. Generally skill training in welding or spray painting in VR costs a lot less since it doesn't require a specialized location, vehicle components to test-paint, or cleanup operations. The use of replica equipment instead of…

Found in Robotics News & Content, with a score of 8.07

…VR offerings. The company's technology is incorporated into the welding and vehicle spray painting applications deployed by Lincoln Electrics and Honda, among others. In Flaim Systems' firefighting applications as well as Sixense's training apps, the use of replica equipment plays an important role. In Flaim Trainer, users use a haptic-enabled water nozzle that can simulate water pressure. In Sixense's spray simulation application, users use an industry-standard paint gun. The incorporation of eye tracking, hand tracking, and replica equipment that help build muscle memory brings AR-VR-powered training to a new level, setting it apart from entertainment applications that focus primarily on…

Found in Robotics News & Content, with a score of 13.79

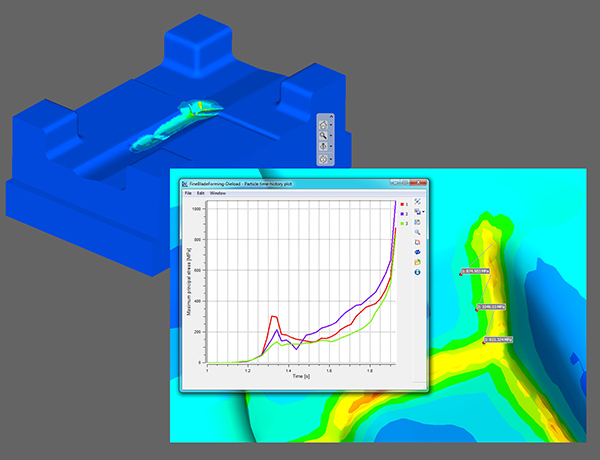

…16 offers one-click import of model data from Simufact Welding and Simufact Additive. For example, users can import two previously welded components from Simufact Welding into Forming and continue modeling a forming process. The company says this method offers minimal effort to achieve a consistent process chain simulation. Users can exchange or transfer data between different Simufact Forming processes. Users can import selected processes with all process properties intact, and use them for subsequent calculations. Version 16 also provides enhanced flexibility, allowing ability to share results with any CAE product. Exported simulation results can be used in other products, such…

Found in Robotics News & Content, with a score of 7.33

…motion control, artificial intelligence (AI) and related automation technologies. Welding, assembly and machine tending robots, mobile robots and human-robot collaborative technologies with intuitive user interfaces and software advances, machine learning and advanced computer vision technologies are just a few of the solutions that will be on display. Many companies will be introducing new technologies never before seen in North America. More than 120 Automate conference sessions explore how automation secures a company’s success in a technologically fast-paced world where AI, IIoT, smart manufacturing, cobots, machine vision and other innovations are rapidly shifting the dynamic of today’s manufacturing. Industry professionals can…

Found in Robotics News & Content, with a score of 12.45

…delved into uncharted territory to create a positive disruption in our industry in much the same way the modern welding processes supplanted rivets, revolutionizing the way ships are built,” said Charles Southall, Newport News’ vice president of engineering and design. “We’re proud to be leading the way.” The Navy hopes to cut lead times on important parts and find a way to produce spare parts at less cost. Source: NavyTimes

Found in Robotics News & Content, with a score of 9.67

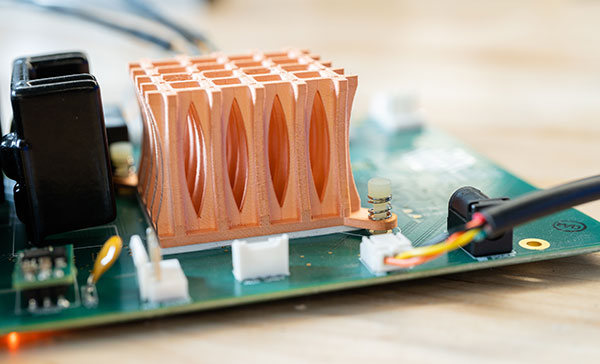

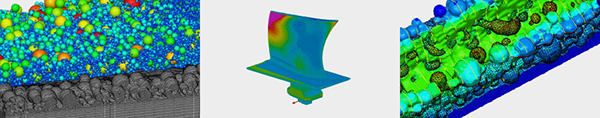

…long history with process simulation for metal manufacturing, including welding, casting and sheet metal forming. ESI Group adds that its AM solution is intended for process and manufacturing engineering departments as well as 3D printing bureaus seeking “first-time-right” prints, shortened time frames and fewer associated costs. ESI Additive Manufacturing supports manufacturers of 3D printed metallic parts in achieving greater productivity, while providing key information on final part quality. Image supplied by ESI Group and courtesy of Volum-e. As detailed on the ESI Group website, the ESI Additive Manufacturing suite offers computational modules for: process window pre-scanning tool; powder coating; melt…

Found in Robotics Companies & Businesses, with a score of 32.06

…AGVs, robotics, and other automated equipment, adding custom components or designing and manufacturing a completely new system. Our automated welding solutions include arc, resistance spot, laser, and stud/nut welding. Heartland’s experienced team is ready to help with start-to-finish service from design through installation and providing all the support that is needed to deliver maximum value to your material handling operation.

Found in Robotics News & Content, with a score of 7.10

…plant. The facility also offers training in materials handling, welding, PLCs and controls, and safety. Phase two, opened in a separate 43,000-square-foot space in 2012, provides space for companies researching and developing autonomous vehicles. Then, a 52,000-square-foot facility opened in 2016 to provide space for startup incubation, and it also houses a training space for manual and automated paint systems used in manufacturing. It is also used by companies to install a new line to train associates before the line goes live in the plant. About 50% of the equipment in the technology center is owned by the vendors whose…

Found in Robotics News & Content, with a score of 7.38

…packaging, quality testing, material handling, machine tending, assembly and welding, currently represent 3% of global robot sales, according to the International Federation of Robotics, but the share is expected to rise to 34% of a $25 billion market by 2025. “This growth will most definitely depend on cobots being used in more applications,” Iversen added. “Their small footprint and ability to work safely alongside humans make them ideal for small and medium-sized manufacturers who need to compete globally. Cobots are also increasingly integrated into very large manufacturers such as automotive plants, where they are taking over processes that can’t be…

Found in Robotics News & Content, with a score of 19.02

…could handle different parts at different stations. For example, welding lock assemblies used to involve an operator who put both parts together manually before inserting them in the welding machine. The new collaborative robots (Universal Robots) and grippers (Robotiq) use plug-and-play components suited to high-mix/low-volume production. The solution also uses a robot-mounted camera able to locate parts in a wide field of view. “When the first robot arrived, the reaction of the people was not very good,” Iosif says. “They said the robot would not be able to produce at the same rate. And, they were right at first.” By…