Editors’ Picks

Found in Robotics News & Content, with a score of 25.61

…3D Printing Solutions (BASF 3DPS). CI’s high-temperature Small Area Additive Manufacturing (SAAM HT) machine will now offer BASF 3DPS’s ABS plastic, carbon fiber PET and recycled PET materials. Ultrafuse ABS is created from acrylonitrile, butadiene and styrene polymers. It has a strong, flexible and heat-resistant nature, according to the companies. It can be used for those looking to manufacture low-cost prototypes, or anyone who wants to create plastic products with ease. Ultrafuse PET CF15 from BASF 3DPS combines processability and low moisture uptake with strength and rigidity. With this PET material, users can 3D print new components that stay functional…

Found in Robotics News & Content, with a score of 20.87

…of industry analysis and market forecasting data to the additive manufacturing (AM) industry, has released its fourth annual market study on the polymer additive manufacturing segment. In the report the firm quantifies the global economic impact of polymer 3D printing including, for the first time, a deep analysis of revenues associated with 3D printed parts. Driven in the long term by opportunities in direct AM production, SmarTech now expects polymer 3D printing to generate $11.7 billion in revenues in 2020, grow to $24 billion in 2024 and as much as $55 billion yearly by the end of this decade. For…

Found in Robotics News & Content, with a score of 18.76

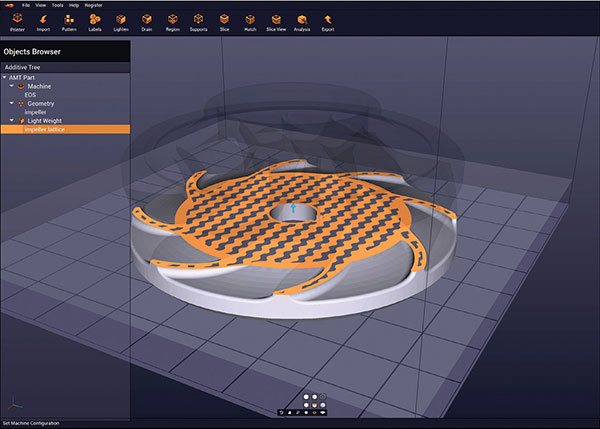

Although additive manufacturing offers clear advantages in many manufacturing applications, current design and simulation resources may be challenged by the complex computational fluid dynamics simulations and shape optimization processes required. Cloud and high-performance computing resources can help companies take better advantage of new design possibilities enabled by 3D printing without requiring a costly investment in new compute resources. 3D print designs that can be simulated and optimized in an HPC environment (on-premise or, increasingly, in the cloud) will be a key enabler of digital manufacturing applications. A number of simulation software vendors, for example, have been working to allow their…

Found in Robotics News & Content, with a score of 38.60

…CGTech and Thermwood will demonstrate simulation capabilities of large-scale additive manufacturing (LSAM) machines. CGTech will be demonstrating its VERICUT software for AM applications, including LSAM machines in booth #1507. Thermwood will be in booth #2432 featuring the capabilities of their LSAM dual gantry and moving table (MT) machines. LSAM is a new technology for large-scale 3D printing of thermoplastic polymers. Thermwood’s LSAM machines use technology to produce the highest quality thermoplastic polymer printed structures available. The machines feature both additive and subtractive heads to accommodate printing and trimming of large scale “near net shape” parts on the same machine. Thermwood’s…

Found in Robotics News & Content, with a score of 23.75

…to provide support and resources. German RepRap has been manufacturing industrial extrusion-based 3D printers since 2010 and counts Airbus Helicopters and Sika Automotive among its users. In 2016, the company expanded its offering with a new Liquid Additive Manufacturing (LAM) technology, which made its debut at Formnext 2018 in the form of the L280 series-ready machine demonstrating compatibility with high-viscosity products like Liquid Silicone Rubber. Arburg has been active in the additive manufacturing market since 2013 following the launch of its open Arburg Freeformer system. Based on the Arburg Plastic Freeforming (APF) process, the technology uses commercially available plastic granules…

Found in Robotics News & Content, with a score of 15.11

…its new training and demo center and will provide additive manufacturing electronic (AME) services locally from the United States. The new headquarters will become the company’s main sales, customer support, logistic and training center. The new facility is being established for the benefit of the company's customers and prospective industry partners. Nano Dimension is also hiring additional personnel in the United States for its AME fabrication facility, producing high-performance electronic devices (Hi-PEDs). “From here the company will launch our AME Service Bureau. There we shall convert digital electronic CAD/CAM files into sophisticated Hi-PEDs, ready to be installed in electronic assemblies…

Found in Robotics News & Content, with a score of 26.68

In late, February 2020, Additive Industries announced the finalists of the Additive World Design for Additive Manufacturing Challenge 2020. From a record number of 151 contestants, professionals and students, three finalists were selected per category. “We are pleased to notice that amount of contestants from all around the world increased, compared to last year, by 25%,” says Daan Kersten, CEO of Additive Industries. “The designs are submitted from all over the world and across different applications fields including automotive, aerospace, medical, tooling and high tech. They all demonstrated how product designs can be improved when the freedom of additive manufacturing…

Found in Robotics News & Content, with a score of 13.05

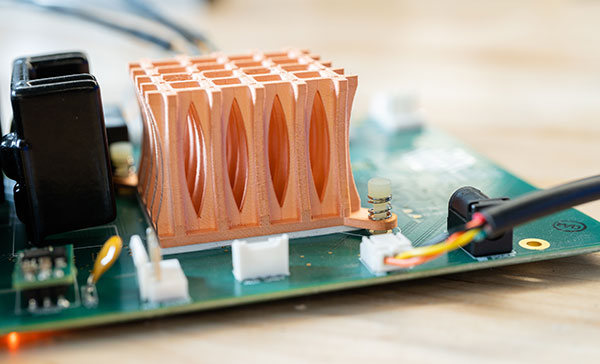

…3D printing copper parts on demand will drive new manufacturing and supply chain efficiencies for customers, leading to reduced lead times and part costs, as well as eliminating the need for costly inventory. Available today, Markforged provides an easy and fast way to produce geometrically complex copper with high electrical and thermal conductivity. “Copper powers our world. It’s everywhere. It builds our cars, enables phones, and keeps electrical equipment running,” says Greg Mark, Markforged CEO and founder. “Copper has traditionally been an expensive and challenging material to machine and incompatible for 3D printing in a pure form with other techniques.…

Found in Robotics News & Content, with a score of 17.75

…U.S. government agencies. Markforged 3D printers are used in manufacturing everything from automobiles to aircraft engines. The company offers metal printers with the entire range of metals—from high-conductivity copper to industrial tool steel to superalloys like Inconel—all in a safe, fast and easy-to-use platform. Its industrial composite platform can print in continuous carbon fiber, Kevlar and more, creating functional parts. Markforged has a strong history of technology involvement in the government and defense sectors, as branches of the U.S. military have hundreds of machines in operation today. The company implemented a forward-deployed metal system to support combat operations and now…

Found in Robotics News & Content, with a score of 44.91

…announces a strategic alliance with Auburn University to accelerate additive manufacturing research and test development. Auburn University is home to the National Center for Additive Manufacturing Excellence (NCAME), which is a founding partner of the ASTM International Additive Manufacturing Center of Excellence (AM CoE). As part of the alliance agreement with the university, MTS will supply test equipment to Auburn's NCAME mechanical testing lab and share expertise to advance mechanical testing methods for additively manufactured materials and components. Auburn University's NCAME and MTS are working together to identify the mechanical testing advancements necessary for further adoption of additive technology. “MTS'…

Found in Robotics News & Content, with a score of 47.22

…Aerospace CTO Russ Dunn will officially open the latest Additive Industries Process and Application Centre close to Bristol in the UK on March 12, 2020. This center is part of the global network of Additive Industries Competence Centres, also located in Eindhoven, Los Angeles and Singapore, each having their own specialty in different aspects of industrial additive manufacturing. The UK & Ireland Process and Application Centre’s core competence will be new materials and process development. The center is located on the historic Filton Aerospace Park, directly in the middle of the growing additive manufacturing hub that is there. Filton has…

Found in Robotics News & Content, with a score of 26.38

…new FFF solution, ROBOZE One+400 Xtreme. CIMP-3D includes several additive manufacturing (AM) systems as well as a design studio and prototyping laboratory. Current research activity within the center is directed at the development of technologies that will enable greater use of additive manufacturing in industry. The ROBOZE One+400 Xtreme will be located within Penn State’s Department of Chemical Engineering. The new 3D printer is specifically designed to produce functional finished parts with high performance and easily prints advanced composite materials suitable for extreme operating conditions. It is equipped to enable new, significant innovations in the FFF 3D printing technology sector.…