Editors’ Picks

Found in Robotics News & Content, with a score of 5.91

…Germany, 3D Systems is showcasing its Figure 4 Standalone plastic 3D printer as a new technology to be integrated in Nokia’s “factory in a box.” The integration of additive manufacturing alongside augmented reality/virtual reality (AR/VR) and robotics, all powered by Nokia private 4G / 5G connectivity, results in a semi-automated production workflow. “After the positive feedback we received for our factory in a box concept last year, it was important to reach a new level with version 2.0,” says Grant Marshall, VP supply network & engineering, Nokia. “We did so in terms of connectivity, because factory in a box 2.0…

Found in Robotics News & Content, with a score of 13.68

…several areas such as food and consumer goods (48%), plastics and rubber (37%), life sciences (31%), and electronics (22%). Shipments to the automotive industry did slow, with 19,178 units shipped to North American automotive OEM and tier supplier customers in 2018 – a 12% decline from 2017. Overall, the automotive industry accounted for just 53% of total robot shipments in North America in 2018, its lowest percentage share since 2010. “While the automotive industry has always led the way in implementing robotics here in North America, we are quite pleased to see other industries continuing to realize the benefits of…

Found in Robotics News & Content, with a score of 2.81

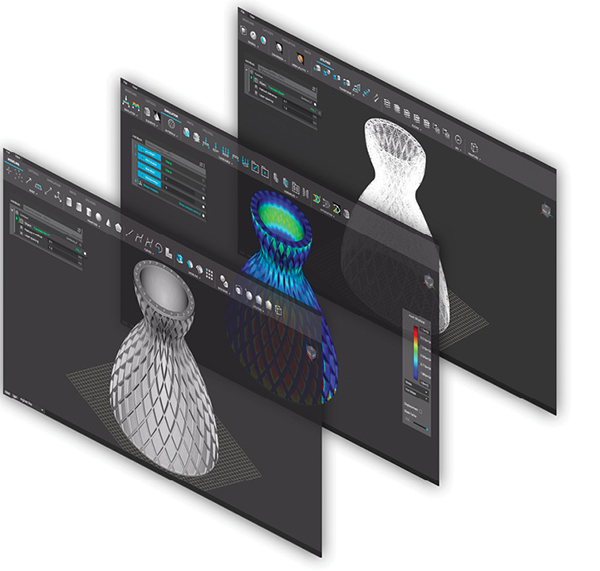

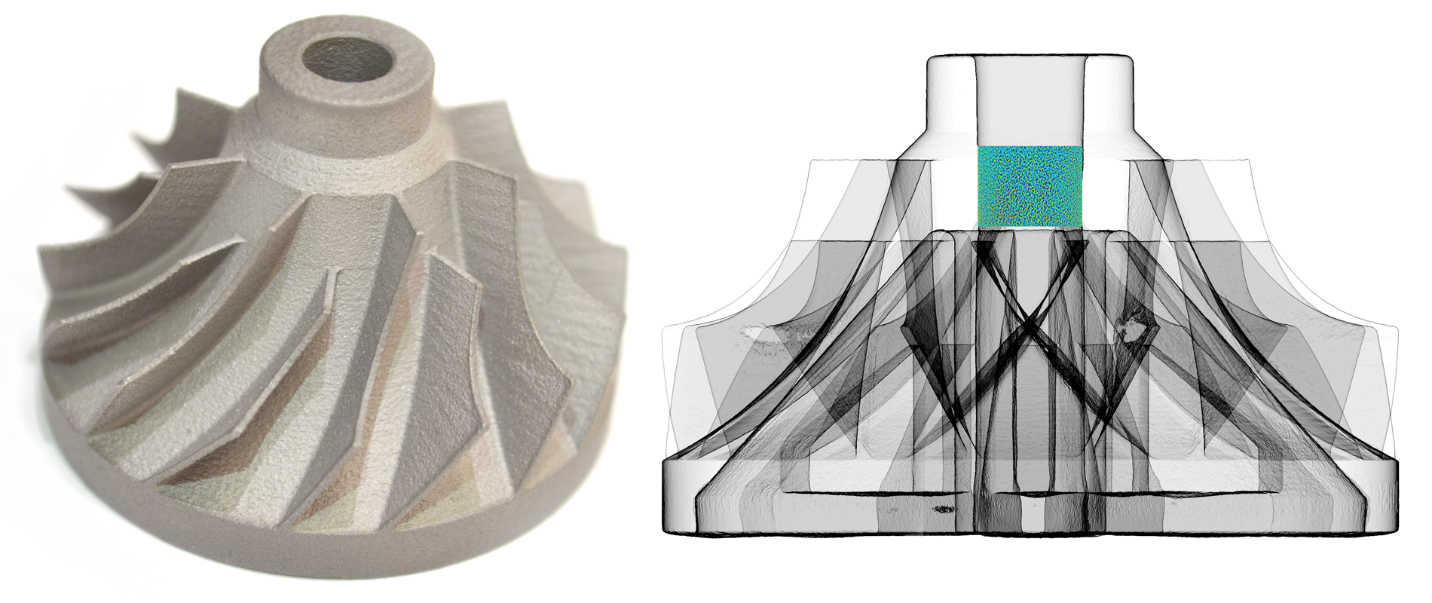

…systems at the time restricted this method to small plastic-based parts in limited quantity, better suited for prototyping than mass production. Recently, generative design has taken a big leap in maturity. With built-in manufacturing constraints, the newer generative design software programs recognize the limits of specific manufacturing methods and can eliminate impractical topological features beforehand. Now, seemingly at a crossroads, generative design is also forced to confront some of the same questions its older CAD and finite element analysis (FEA) siblings have had to wrestle with in their own timelines of maturity. Who is generative design for, the novices or…

Found in Robotics News & Content, with a score of 12.62

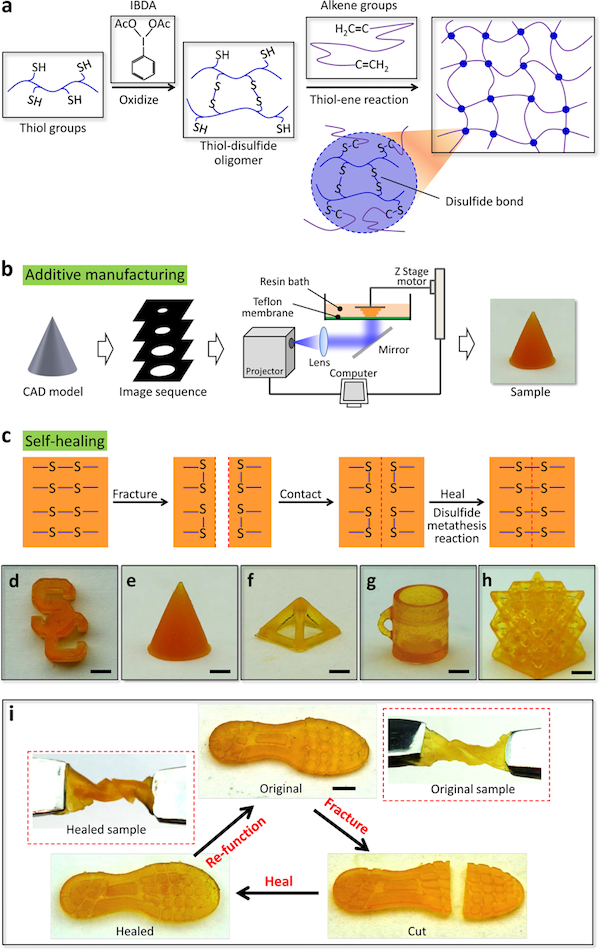

…self-heal” The researchers plan to develop different self-healable materials along a range of stiffnesses, including soft rubber and rigid hard-plastics. Source: USC

Found in Robotics News & Content, with a score of 8.83

…with speed and agility.” Availability Jabil Engineered Materials will be available starting this month through distribution partners, including Chase Plastics and Channel Prime Alliance. Print profiles for Jabil Engineered Materials also will be available through Ultimaker Cura software with links to Jabil’s distribution partners. More Info Jabil Sources: Press materials received from the company and additional information gleaned from the company’s website.

Found in Robotics News & Content, with a score of 9.90

…rise in polymer materials for 3D printing It’s the plastic materials for 3D printing that have been preparing for substantial growth in 2019. Major material manufacturers are playing a big role in this movement. The rise of the application-driven approach towards innovation in 3D printing is a contributing factor. As industries identify relevant applications for 3D printing, material manufacturers will be driven to develop and certify new materials to suit those applications. The rise of manufacturing applications, as opposed to prototyping ones, is fueling a growth in materials development. The same rise is also likely to bring a new challenge:…

Found in Robotics News & Content, with a score of 3.79

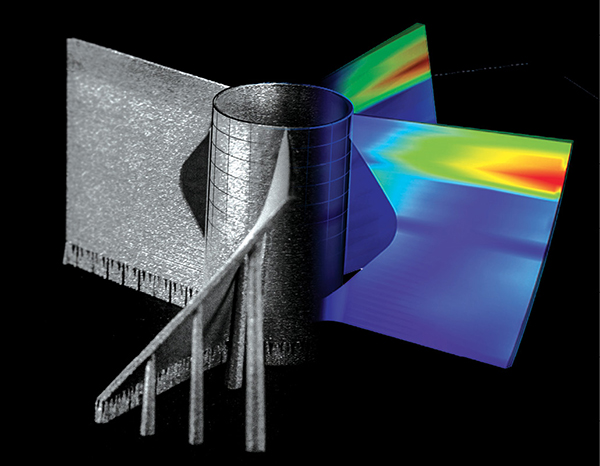

…says that Materialise worked with one customer on the plastics side that was able to decrease production time by more than 40% after simulating changes in the part orientation and machine behavior. “That shows you the power of simulation,” he says. “The machine is 40% more productive after altering the production flow. That’s something you’ll see happening more in these volume manufacturing lines.” Stucker adds that there will be a bigger push for more microstructure and property prediction capabilities. “Long term, people want to optimize performance of the component through a combination of geometries and properties and we need simulation…

Found in Robotics Companies & Businesses, with a score of 26.98

Epson Robots said it is a global leader in PC-controlled precision factory automation, with over 100,000 units sold worldwide and a product line of hundreds of models of easy-to-use SCARA, Cartesian and 6-Axis robots based on a common PC-based platform. Building on a 35-year heritage, Epson Robots delivers robots for precision assembly and material handling applications. It serves the aerospace, appliance, automotive, biotechnology, consumer product, electronics, food processing, medical device, pharmaceutical, plastics, semiconductor, and telecommunication industries.

Found in Robotics News & Content, with a score of 8.29

…units), food and consumer goods (24% to 1,747 units), plastics and rubber (16% to 470 units) and electronics (14% to 1,280 units). RIA believes that as robots have become more dexterous, safer, and available in a variety of form factors they have become more appealing to new users in a wide variety of industries. “Despite the cyclical swing in automotive orders, which we’ve seen before, interest in new robotics technologies continues to grow,” said Jeff Burnstein, president of RIA. “Today’s robotics industry offers innovative products, competitive advantages, and fulfilling employment opportunities for a wide variety of companies. We’ve been saying…

Found in Robotics News & Content, with a score of 3.40

…to expose internal details (which may be fine for plastic AM parts), non-destructive inspection is highly desirable for qualifying and verifying aerospace, automotive and medical final products. Internal components of a Zeiss Xradia 520 Versa, property of the Multi-Scale Additive Manufacturing Lab of the University of Waterloo. X-rays are emitted in a cone beam from the X-ray Source Assembly and travel through the Sample to the X-ray Detector to collect a 2D radiograph. The Sample is incrementally rotated through 180° or 360° to collect several hundred to several thousand radiographs, which are reconstructed into a 3D image. Image courtesy Expanse…

Found in Robotics News & Content, with a score of 4.68

…mixture is dried and then shredded to obtain small plastic pellets containing gold nanoparticles. After a part is printed, it is inspected by a special ultraviolet-visible spectrophotometer for defects. The scientists contend that the process can detect defects invisible to the eye. “Parts printed with the “nanofunctionalized” filament are unique in the fact that the sensing capability is embedded directly within each print layer and throughout the entirety of the part,” says Cole Brubaker, a member of the Vanderbilt research team and lead author of the paper “Nondestructive Evaluation and Detection of Defects in 3D Printed Materials Using the Optical…

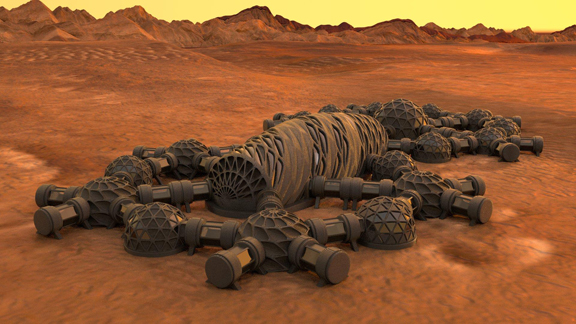

Found in Robotics News & Content, with a score of 10.90

…loose sediment (soil, dust, broken rock, etc.) and recycled plastic. The sediment, known as regolith, can be widely found on Earth, other planets, the moon, and even asteroids ... Based on NASA specifications, Autodesk’s Advanced Consulting team designed the barrier using tools such as Fusion 360 and PowerMill to comply with structural as well as robotic extrusion requirements while achieving significant weight reduction. Autodesk also developed the software to control the industrial robot arm ...” The proof of concept is a success, according to Autodesk. “The first artifact that NASA has printed using this approach is a Jersey barrier—one of…