Editors’ Picks

Found in Robotics News & Content, with a score of 23.79

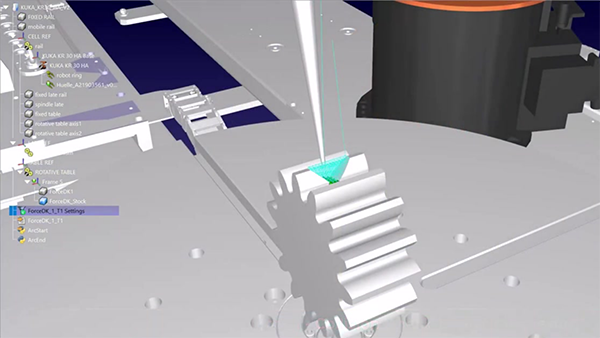

…a recent collaborative effort with FORCE Technology and Hexagon Manufacturing Intelligence using ESPRIT additive toolpath programming, an industrial robot was programmed using RoboDK’s simulation software. ESPRIT and RoboDK, a powerful combination of toolpath programming and robot digital twin with post-processing and analysis capabilities, were used to create the final part. The system included a 6-axis KUKA robot arm mounted on a rail (linear axis), a tilting table for rotary operation, and a spindle. Additionally, a GTV cladding head (powder+laser) enabled additive functions resulting in an overall cycle time of 5 minutes when reloading Steel 4140 parts. This project examined the…

Found in Robotics News & Content, with a score of 23.78

At the Additive Manufacturing Users Group (AMUG) conference in Chicago last month, a lunchtime conversation summed up the state of additive manufacturing/3D printing technology, and many other technologies. A large supplier to the aerospace industry was voicing a minor complaint about his company’s 3D printers to a representative from a competing 3D printer company. That representative, as you might expect, said his company’s 3D printers did not suffer from that particular malady. “Where were you five years ago when we did all this?” asked the aerospace supplier. “We weren’t a company yet,” replied the 3D printer manufacturer. It was a…

Found in Robotics News & Content, with a score of 23.75

…to provide support and resources. German RepRap has been manufacturing industrial extrusion-based 3D printers since 2010 and counts Airbus Helicopters and Sika Automotive among its users. In 2016, the company expanded its offering with a new Liquid Additive Manufacturing (LAM) technology, which made its debut at Formnext 2018 in the form of the L280 series-ready machine demonstrating compatibility with high-viscosity products like Liquid Silicone Rubber. Arburg has been active in the additive manufacturing market since 2013 following the launch of its open Arburg Freeformer system. Based on the Arburg Plastic Freeforming (APF) process, the technology uses commercially available plastic granules…

Found in Robotics News & Content, with a score of 23.73

…“We are pleased to partner with VELO3D to help manufacturing companies across the U.S. produce mission-critical parts for industrial use,” states Ken Clayton, CEO of GoEngineer. “VELO3D delivers breakthrough SupportFree technology for the design and manufacturing of metal parts that are not hindered by geometric constraints nor compromised by part quality. Metal additive manufacturing is an important piece to GoEngineer’s portfolio and we are excited to help our customers differentiate themselves even more.” “GoEngineer has gained the trust of thousands of customers with their rich expertise in additive design solutions. I see them as a strategic and invaluable partner in…

Found in Robotics News & Content, with a score of 23.68

With LulzBot 3D printers at the starting line, Nelson Racing Engines burns rubber, not cash. Watch as they unleash “race car power with street car manners” while saving thousands of dollars on prototyping via additive manufacturing. “Obviously in a shop like this you need a lot of tools…one of the tools we have that’s been amazing for us lately is the 3D printer we have from LulzBot.” —Tom Nelson, Builder and Fabricator at Nelson Racing Engines LulzBot hardware is made in the USA using domestic and imported parts.

Found in Robotics News & Content, with a score of 23.66

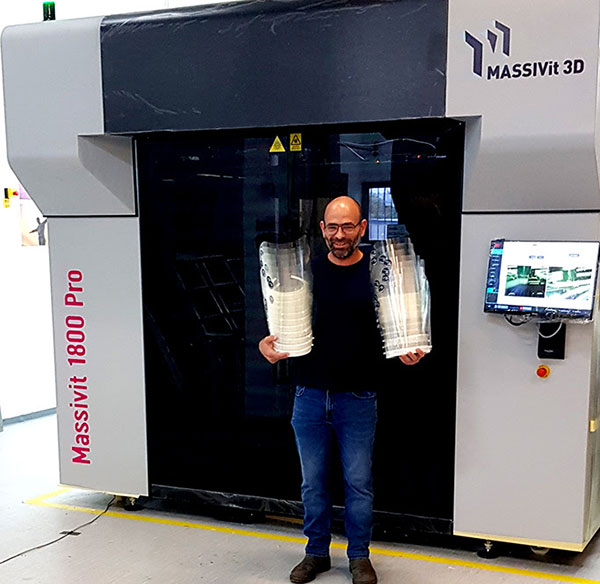

…for the victims of the pandemic. Massivit 3D’s high-speed additive manufacturing technology allows for the supply of hundreds of face shields off each machine every day. In addition to devoting all of its manufacturing resources to producing and donating thousands of face shields to medical teams at local hospitals with a less than one-day turnaround, the company has also made available to all, the optimized 3D print files of the newly developed face shields. The Massivit 3D global network of customers and distributors are also making Massivit 3D printers available for this effort, supplying face shields to health workers in…

Found in Robotics News & Content, with a score of 23.55

…recently selected its VELO3D Sapphire system. Chromalloy will use additive manufacturing for maintenance, repair, and operations (MRO) projects in the aviation and energy markets. Palm Beach Gardens, Fla.-based Chromalloy develops systems to reduce operating expenses and extend the life of gas turbine engines. The company, a subsidiary of Sequa Corp., is authorized by the U.S. Federal Aviation Administration, the European Union Aviation Safety Agency, and other national aviation authorities. It is also qualified under ISO (International Organization for Standardization) and National Aerospace and Defense Contractors Accreditation Program. Chromalloy to use AM to extend engine life Industries are increasingly adopting additive…

Found in Robotics News & Content, with a score of 23.54

…V650 Flex 3D printer. Available from Stratasys, Stratasys Direct Manufacturing, DSM Somos-verified resins enable customers to produce durable parts that meet requirements of a wide range of applications. “While stereolithography is one of the original 3D printing processes—mainly used to create master patterns or large concept models quickly and accurately – customers have been challenged by restricted systems that can’t be configured and materials at a high cost-per-part,” says Omer Krieger, EVP Products, Stratasys. “The V650 Flex is the result of customer demand around the world wanting a better solution—fully configurable to match the specific application and use-case.” With a…

Found in Robotics News & Content, with a score of 23.53

Structur3d—a company in the advanced additive manufacturing market space for soft materials—makes available the Inj3ctor Platform, a new desktop solution for injection molding rubber parts. The company is advancing and solidifying 3D printing’s role within industrial manufacturing by expanding its material capabilities to create new products with factory-grade rubber materials, like silicones and polyurethanes, the company reports. The Inj3ctor is a solution to combine the principles of injection molding with 3D printing. Using 3D-printed molds, the Inj3ctor uses curated material cartridges to mix and inject 2-component (2K) flexible materials into any customizable shape, enabling turnkey, small-batch manufacturing of rubber materials.…

Found in Robotics News & Content, with a score of 23.25

…Radel polyphenylsulfone (PPSU) to e-Xstream’s latest release (2019.0) of Digimat-Additive Manufacturing (AM) software. These products complement the neat KetaSpire PEEK AM filament already available for simulation on e-Xstream engineering’s Digimat-AM platform. “Our growing range of AM filaments underscores Solvay’s determination to establish itself as an industry leader in this rapidly evolving market,” says Christophe Schramm, Additive Manufacturing business manager in the company’s Specialty Polymers global business unit. “DigimatAM allows customers to simulate the printing process and successfully predict the thermomechanical behaviour of 3D-printed designs in order to ‘print right the first time’.” These new materials will benefit from e-Xstream engineering’s…

Found in Robotics News & Content, with a score of 23.11

Adding a new page to its high-performance, additive manufacturing playbook, Stratasys today inked an agreement with Arrow Schmidt Peterson Motorsports, which competes in the NTT IndyCar Series. The team is leveraging Stratasys’ Fortus 450mc 3D Printer—capable of printing carbon fiber-reinforced FDM Nylon 12—and F370 3D Printer as part of its manufacturing process. The Fortus 450mc 3D Printer offers FDM Nylon 12 Carbon Fiber and ASA materials. This technology is aimed at creating functional prototypes, product components, and rugged tooling that match demands for strength and stiffness of carbon-filled composite material. “Competitive racing is the ideal test track to demonstrate the…

Found in Robotics News & Content, with a score of 23.03

Renishaw will return to the Additive Manufacturing Users Group (AMUG) conference to be held at the Hilton Chicago March 31 to April 4. Renishaw will exhibit components from the aerospace, automotive, medical and marine industries, as well as consumer technology, in booth D14. “We’re exhibiting parts from a range of industries to showcase what is possible with AM,” says Marc Saunders, director of Additive Manufacturing Applications at Renishaw. “We are even exhibiting the galvanometer mounting, which is a core component of the optical system on our latest machine, the RenAM 500Q.” Advanced automotive technology on display will include LED heat…