Editors’ Picks

Found in Robotics News & Content, with a score of 5.25

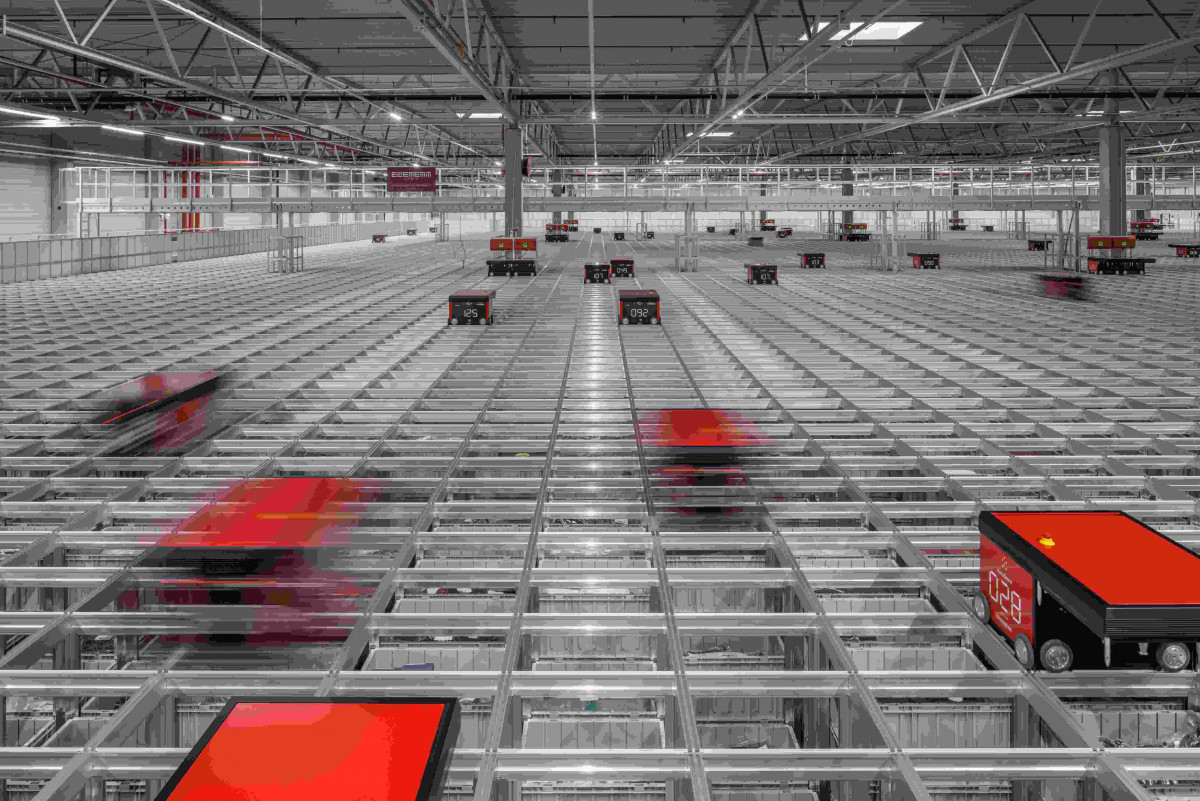

…will also use robots for locating, tracking, and moving inventory as part of Geek+'s goods-to-person system. This method allows orders to be delivered directly to pick-and-pack stations, eliminating any movement time needed by operators to search for items, said the partners. In addition to improved real estate utilization, AMRs can minimize manual labor and reduce the risk of human error while also improving picking accuracy and reducing inventory count errors, said Geek+. Robots can also mitigate some of the challenges brought on by COVID-19, such as social distancing protocols in warehouses. GEODIS said that the Geek+ system advances its digital-first…

Found in Robotics News & Content, with a score of 5.25

…look for ways to optimize warehouse space, intelligently manage inventory and increase the productivity of the existing labor pool. One of the best routes for warehouses and fulfillment centers to be more productive is through automation and robotics that can be tailored to a company’s unique workflows and service needs. inVia Robotics' “The New Way to Warehouse” white paper describes four productivity-boosting strategies for e-commerce distribution centers to realize favorable results and quickly capture a measurable return on their investment. 1. Intelligent inventory placement and management Before the recent surge in e-commerce, warehouse automation involved managing bulk pallets with as…

Found in Robotics News & Content, with a score of 5.25

…picking stations to increase throughput, said Romaine. This optimizes inventory without the need for manager intervention, he noted. The Go-Fer Bot can increase pick rates, ranging from more than 300 lines and up to 1,000 items per operator, per hour, said Conveyco. Romaine said the company's AMRs, software, and modular shelving allow for a wider variety of inventory than ASRS, including loose pieces, cases, totes, hanging garments, and different pallet positions. Conveyco claimed that its system can save up to 75% of floor space and provide 99.9% accuracy. It can also be increased or decreased in size depending on need,…

Found in Robotics News & Content, with a score of 5.23

…six different brands within the same building for existing inventory. Before GreyOrange, the brands coexisted, but their online and retail sides were handled separately. Now, it's all in the same mix of inventory. The channel gets decided when an item goes outbound, packed in a box or an individual carton. We've seen this need for nuance in the industry for a long time. For brands to effectively adopt automation, they need a common ERP [enterprise resource planning system] and operations. We developed GreyMatter around that need for orchestration. How does that compare with most retail today? Kohli: The idea of…

Found in Robotics News & Content, with a score of 5.21

…units per month, even during peak times Increased warehouse inventory capacity by 10X (Storing 4.2M units in 100k square feet) Shortened order fulfillment times from days to hours for priority shipments Reduced energy costs by up to 85% Increased inventory accuracy to 99% “At PUMA, our mantra is forever faster, and that includes getting our products in the hands of our customers. AutoStore enables us to be the fastest we’ve ever been,” said Bob Philion, PUMA North America president. “With the rise of e-commerce, we’re seeing a higher volume of orders moving through our facilities, in addition to more frequent…

Found in Robotics News & Content, with a score of 5.16

…more efficient tracking “The AutoStore system there allows merchandise inventory to be fully monitored and controlled, ensuring high efficiency in storage and retrieval,” the company said in a statement. “This enables customer orders to be processed and shipped with greater speed and reliability.” “The interplay of the flexible and modularly expandible robotics solution with the local employees reduces throughput times for individual customer orders, from order placement to dispatch from the warehouse, simplifies operational processes for employees, and increases operating efficiency,” the company added. It all starts with a 16-level high aluminum framework where inventory is stacked and stored in…

Found in Robotics News & Content, with a score of 5.14

…complement current order fulfillment practices with value-added service offerings. Inventory accuracy: Directed by advanced software, including a facility’s warehouse management system (WMS) and warehouse control system (WCS), pallet placement within the AS/RS is tracked and monitored. That level of automated control removes the chance of an operator forgetting to scan the pallet license plate number (LPN) to a location. The tracking also ensures that established inventory cycling practices, such as first-in/first-out (FIFO) or last-in/first-out (LIFO), are consistently followed - preventing waste due to expiration. Labor savings: Eliminating manual pallet load handling can reduce labor costs by 50% or more. Facilities…

Found in Robotics News & Content, with a score of 5.14

…has become more complex with increased consumer expectations for inventory and same-day deliveries,” said Andre Luecht, global strategy lead, transportation, logistics and warehousing at Zebra Technologies. “Zebra helps businesses work in new ways with technology and automation to drive the right outcomes in their operations and build an agile supply chain through better accuracy, visibility, and efficiency.” According to the study, eight in 10 decision-makers and frontline workers said using more technology and automation would help meet or exceed productivity goals. In addition, decision-makers (54%) and workers (49%) agree addressing worker comfort and ergonomics is a top workforce initiative. What…

Found in Robotics News & Content, with a score of 5.14

…operations, by empowering on-site associates with daily tasks, including inventory replenishment, picking, sorting and packing. “Shopify is taking on fulfillment the same way we’ve approached other commerce challenges, by bringing together the best technology to help everyone compete,” said Tobi Lütke, CEO of Shopify. “With 6 River Systems, we will bring technology and operational efficiencies to companies of all sizes around the world.” “By joining Shopify, we’re changing the game of fulfillment. Together, we will help thousands of businesses improve their fulfillment operations, with an easy-to-learn solution that can more than double productivity and improve accuracy,” said Jerome Dubois, co-CEO…

Found in Robotics News & Content, with a score of 5.13

…a network of automated MFCs with Fabric to house inventory on behalf of grocers so its own investments may off-set the potentially reduced number of facilities installed by grocers.” If I understand the model correctly, Instacart’s MFCs would essentially be small 3PLs located near customers to provide fast, home delivery for a variety of customers. Some inventory could be evergreen and used for all customers – Cheerios, after all, is Cheerios regardless of what grocer or convenience store you buy it from – and private-label or chain-specific inventory could be managed like inventory in any other 3PL. “When we did…

Found in Robotics News & Content, with a score of 5.11

…to the next location and guiding them through the required tasks or steps to complete processes, such as picking, inventory replenishment, maintenance and repairs.

Found in Robotics News & Content, with a score of 5.10

…capacity. If your order volume increases, so must your inventory. As orders continue to come in, you’ve got to carry more and more stock. After a certain point, you’re carrying too much inventory and it’s time for a new building, right? Maybe. Mike Myers of ODW Logistics extended the life of his building by increasing his team’s efficiency: more orders, same space. Joanne Hoberg, VP of Solutions and Engineering, NFI: “We reduced time to achieve performance objectives by 90% by minimizing time spent learning processes and the warehouse floor.” We’ve said it before, we’ll say it again: training time matters…