Editors’ Picks

Found in Robotics News & Content, with a score of 5.03

…can provide challenges, which can typically be solved by cleaning the chargers.” “LilBuddy AMRs are remarkable, streamlined robots. Despite their compact size, they’re capable of moving loads in excess of 220 lb.,” stated Ben Waters, CEO of WiBotic. “They are perfect for navigating smaller spaces and – when integrated with our wireless charging capabilities – offer a compelling, low-maintenance solution for organizations looking to introduce autonomous mobile robots into their operations.” “We're excited about this collaboration and that ResGreen can use wireless power for LilBuddy,” he told Robotics 24/7. “Its value proposition resonates with wireless charging.” WiBotic adds resilience to…

Found in Robotics News & Content, with a score of 4.97

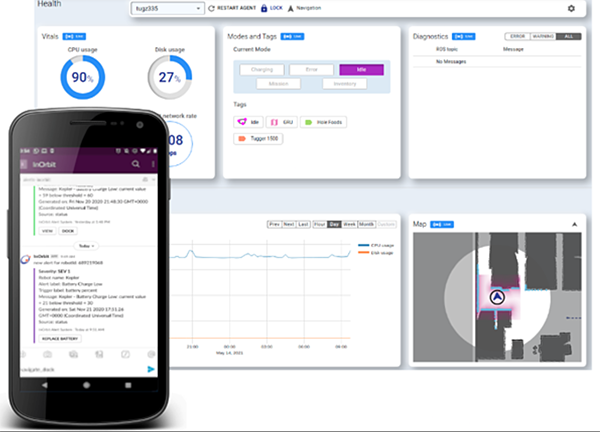

…path than flexibly following goals. A lift truck or cleaning robot can navigate around people.” The MassRobotics standard uses the WebSocket API (application programming interface). In yesterday's demonstration, the display consisted of a Vecna map with Waypoint and WiBotic information published to it. Shared map created from Vecna, Waypoint, and WiBotic data using the MassRobotics interoperability protocol. More status reports to come “The MassRobotics standard makes it easier for the ecosystem to adopt multifleet plug-and-play operations,” said Theobald. “The most common feedback we've had is that it takes a couple of hours [in comparison with the time it would take…

Found in Robotics News & Content, with a score of 4.95

…intrusion, a 13% height reduction, and fewer surfaces requiring cleaning. Software and customization “While most of our enhancements were focused on Flippy’s hardware and design, we also introduced additional software updates to operate the AutoBin system and allow Flippy to perform additional cooking tasks,” Bell said. “And since Flippy is essentially built on an AI platform, it is constantly learning how to recognize and cook new food items, making it easy to install and customize, depending on each kitchen’s menu and needs.” “Not only are we able to customize and program Flippy to meet the specific needs of each kitchen…

Found in Robotics News & Content, with a score of 4.66

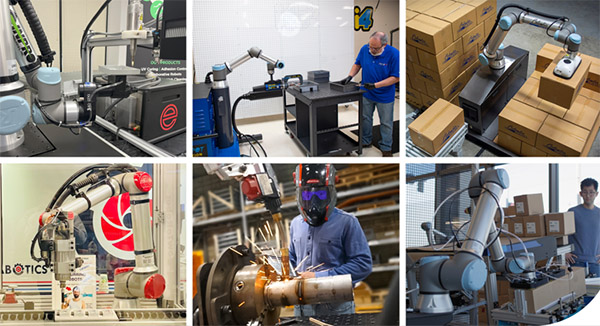

…using ATI tools and its own proprietary, recycled CO2 surface-cleaning technology. The new Operator Interface from Robot27 allows operators to easily access and run pre-programmed functions without touching the UR teach pendant. Machine operators can execute these tasks with just a few clicks and with no possibility of altering any programming. “Attendees visiting our Automate booth will quickly realize how our ecosystem continues to innovate on our platform,” stated Joe Campbell, senior manager of applications development at Universal Robots. “We’re constantly collaborating with partners on addressing new automation frontiers, with Automate being the perfect discovery pad for our rapidly expanding…

Found in Robotics News & Content, with a score of 4.62

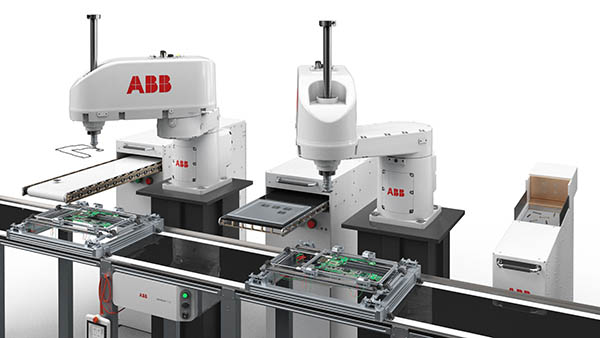

…semiconductor manufacturing ranges from edge grinding, surface polishing, and cleaning to loading finished chips for testing, final packaging, and palletizing. Midstream electronics manufacturing encompasses electronic components manufacturing and assembly onto printed circuit boards. Here, robots are used to handle the placing of components onto circuit boards prior to soldering. “Circuit-board handling using collaborative robots for transporting between stations, as well as to automate circuit testing, is a key area for automation in this space,” added Alphonse. The downstream use of robotics in electronics manufacturing focuses on the assembly of final goods, such as consumer electronics. Robotic automation at this stage…

Found in Robotics News & Content, with a score of 4.61

…and cost savings using the cobot and motion control system. Previously, 80 percent of the plasma-cutting time was spent cleaning up the waste from the manual cuts. On a single large truck body contract over the subsequent three years, Levesque determined that the trimming process on that project alone would be more than 50 hours for every truck. Moving to a cobot application reduced that time to 12 hours per truck, ultimately saving 1,000 hours and realizing a significant cost savings on this project.

Found in Robotics News & Content, with a score of 4.55

…“Next Generation Robotics provides algorithms for routing tugs and cleaning robots, all in the same warehouse,” Pestoni said. “We can connect and control them, and now these robots need to know how to optimize routes second by second.” “Just as public restrooms used to have clipboards with sheets to say when they were last cleaned; now, we can do that for every square foot of an airport,” he explained. “If you combine that rich data from the robot's operation with secondary data, people and robots can do smarter things.” “We've worked with IoT companies in warehouses. In addition to autonomous…

Found in Robotics News & Content, with a score of 4.53

…systems for advanced fueling options, 360-degree perception, and onboard sensor-cleaning systems. It also highlighted patents for systems to reduce energy consumption, sharing information about road closures between autonomous vehicles (AVs) and updating Autonomous Freight Network routing plans, and a Mobile Launchpad for AVs to reduce the need for driver interventions during the loading and landing process. “TuSimple’s patent portfolio reflects our best-in-class technology development and strong progress in bringing autonomy to the market,” stated Paul Liu, global head of intellectual property at TuSimple. He spoke with Robotics 24/7 about TuSimple's patent portfolio and technology strategy. TuSimple builds portfolio with the…

Found in Robotics News & Content, with a score of 4.45

…machine learning models using a variety of classifiers, providing initial results that were between 75% and 80% accurate. After cleaning and reducing the raw data, the process was repeated and classifier accuracy improved significantly, to over 95%, according to the article.

Found in Robotics News & Content, with a score of 4.33

…returned to storage or the empty is sent for cleaning and reuse. At that point, the target bins are sent to a shuttle system that serves as temporary buffer storage until all the items for an order have been picked and are ready for consolidation at a packing station. Packing Full pack orders that ship in their original packaging go directly to packing; or, if they are part of a multi-line order, go to buffer storage to be consolidated later. At packing, the system prints out any required delivery instructions followed by a handling label that informs the shipping sorter…

Found in Robotics News & Content, with a score of 4.27

…just in Paris. I saw robots in malls and cleaning hotels, and I expect to start seeing more in the U.S. This frees up people to do more high-value work. Indxx also has a Global Robotics & Artificial Intelligence index. What challenges does that focus on? Sharma: It focuses on industrial automation, non-industrial robotics, and on AI and unmanned vehicles and drones. Last-mile problems are tough for autonomous vehicles. There are a few core issues that will take time and effort to solve. From an AI perspective, people don't really understand how they do what they're doing. You have to…

Found in Robotics News & Content, with a score of 4.23

…should rank higher on the list of to-dos than cleaning out the cellar or reorganizing the garage. That said, many reverse-logistics operations remain primarily manual, noted Chris Rowland, director of solutions consulting at Honeywell Intelligrated. But manual processing is in the early stages of turning to automation, according to industry experts interviewed for this article. “Automation in reverse logistics is not just a trend, it’s a reality,” explained Monty McVaugh, manager of the product management group at OPEX. He cited several factors beyond the increasing number of returns as e-commerce grows. Increased volume requires increased speed of processing returns, and…