Editors’ Picks

Found in Robotics News & Content, with a score of 15.41

…product launch plans, which remain a top priority as we lead the industry to new heights with our best-in-class additive manufacturing solutions,” Zeif adds. Stratasys expects the resizing effort, in conjunction with other cost-mitigation measures, to reduce annualized operating expenses by approximately $30 million. The company will incur a charge of approximately $6 million in severance costs, primarily in the second quarter of this year. Sources: Press materials received from the company and additional information gleaned from the company’s website.

Found in Robotics News & Content, with a score of 19.41

HP is delivering a polypropylene (PP) material for additive manufacturing. The new HP 3D High Reusability PP, enabled by BASF, is a durable and chemically resistant material that has been qualified for HP’s production-grade 3D printing systems, and is ideal for customers in the automotive, consumer, industrial and medical sectors. HP also unveiled a new partnership with Oechsler, a global design and manufacturing player, to develop applications for both the new PP and HP’s broader materials portfolio, as well as new customer Cobra Golf for its Metal Jet 3D printing technology. Door defroster vent used in the ventilation system of…

Found in Robotics News & Content, with a score of 15.93

…costs associated with operational inefficiency, by enabling decentralization of manufacturing and production on demand. The technology is also known for its ability to enable new business models such as mass production of customized products, and bring innovation to market in record time. However business leaders frequently cite one barrier against the widespread adoption of 3D printing: the lack of know-how. Materialise conducted a survey last year which illustrated nearly 50% of manufacturers expect the use of 3D printing to double in the next 5 years, but 41% see the lack of expertise as a major hurdle. Materialise says Mindware can…

Found in Robotics News & Content, with a score of 53.85

…of the leading machine manufacturers to validate their new additive cycles. The DP Technology teams announce the first commercial version of ESPRIT that includes additive direct energy deposition (DED) cycles. ESPRIT’s additive capabilities include the same intuitive user interface that users expect from the software. The product release includes three-, four- and five-axis DED support. Combined with the subtractive processes and embedded into a single software, DP Technology brings a spectrum of support to hybrid manufacturing. ESPRIT’s additive DED cycles include additive simulation and verification, as well as global support from ESPRIT’s technical teams. DP Technology validated their post-processor through…

Found in Robotics News & Content, with a score of 28.63

…a reseller partnership with 3DZ Group, southern Europe’s largest additive manufacturing value-added reseller, providing products from top-tier brands like 3D Systems, HP, Markforged, Formlabs, Artec and Materialise, along with training, maintenance and on-demand 3D printing to blue-chip clients across Europe and around the world. For several years, 3DZ has offered consultancy and services in the additive manufacturing industry. “Nexa3D empowers us to offer very compelling design agility, and a supply chain resiliency solution in a post Covid-19 period in which we believe that super-fast large-format additive manufacturing together with high performance, high temperature durable photopolymers will be highly prized by…

Found in Robotics News & Content, with a score of 36.11

…and Advanced Laser Materials (ALM), a materials developer for additive manufacturing (AM), makes available polypropylene (PP) powder for selective laser sintering (SLS) industrial 3D printing. Braskem and ALM began their partnership in 2018, focusing on the development of polyolefin-based powders for SLS. This new polypropylene powder for SLS is launched under the joint collaboration. The launch brings enhanced benefits to the SLS AM process including lightweighting, moisture resistance, living hinge capabilities, improved recyclability, chemical resistance, enhanced processing stability as well as elongation at break and flexibility is comparable to injection molding PP grades. “Looking to the future, we see exciting…

Found in Robotics News & Content, with a score of 19.01

3D Systems’ Board of Directors named manufacturing CEO veteran Dr. Jeffrey A. Graves as the new president and CEO, effective May 26. Graves brings 17 years of CEO experience and a proven track record for leading, operating and growing technically complex businesses, the company says. He replaces Vyomesh Joshi (VJ), who announced his retirement in February. “I am incredibly excited about the opportunity at 3D Systems. Digital manufacturing will play a key role in the transformation of manufacturing, and 3D Systems is uniquely positioned with its portfolio of additive manufacturing systems, material science, software and domain expertise to help companies…

Found in Robotics News & Content, with a score of 9.81

Additive manufacturing companies have been active during the worldwide pandemic and shutdown, helping health care providers and other companies address supply chain shortages. Digital Engineering spoke to Jonah Myerberg, co-founder and CTO at Desktop Metal, about the company’s activities and experiences during the COVID-19 shutdown. DE: Desktop Metal has been involved in rapidly developing and producing a new COVID-19 nasal test swab. Can you tell me about that project? Jonah Myerberg: Although swabs are not made of metal, this was an initiative we identified right away where we could help. This wasn’t something we could print out metal or even…

Found in Robotics News & Content, with a score of 38.12

…exchanger. The part is being developed using a metal additive manufacturing process for possible integration onto GA-ASI's line of remotely piloted aircraft systems (RPAS). “GA-ASI and Conflux are developing novel and state-of-the-art thermal solutions for application to our existing and next generation RPAS. This will allow enhanced endurance and lower manufacturing cost, as well as more flexibility in our product design and integration,” says Linden Blue, GA-ASI CEO. Conflux Technology is an additive manufacturing applications company based in Geelong, Victoria, Australia, that specializes in thermal and fluid engineering. Conflux is providing design expertise in the optimization of Additive Manufacturing heat…

Found in Robotics News & Content, with a score of 50.55

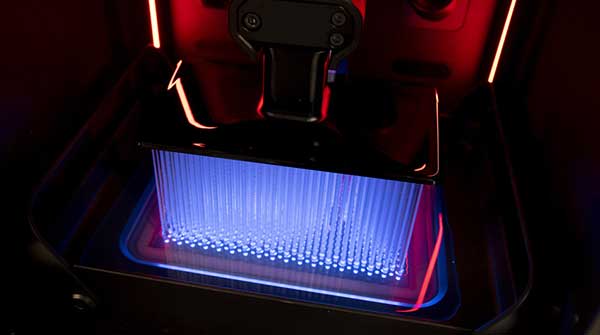

…the ESPRIT CAM system, is enhancing its support of additive manufacturing processes with a new software specifically for the powder bed fusion market. Called ESPRIT Additive for Powder Bed, the program comes as an add-in application for SolidWorks, a computer-aided design (CAD) program. ESPRIT Additive for Powder Bed Fusion is compatible with any file supported by SolidWorks. One standout feature of the new software is the patented Part-to-Build When preparing a part for manufacturing, the program automatically assigns exposure strategies based on simple inputs from the user. ESPRIT Additive for Powder Bed Fusion also introduces a slicer that offers accuracy…

Found in Robotics News & Content, with a score of 10.47

Origin, developer of an open platform for additive mass manufacturing, is collaborating with Beth Israel Deaconess Medical Center (BIDMC) to find a solution for manufacturing COVID-19 test swabs. Over the last 2 weeks, Origin has quickly shifted its resources from being a 3D printer manufacturer to become a medical device manufacturer and has started production to address the shortage of COVID-19 test kit supplies. BIDMC, an academic medical center affiliated with Harvard Medical School, selected Origin's 3D-printed test swab to be part of a clinical trial to evaluate it for efficacy and safety. Origin's 3D-printed swab passed a rigorous initial…

Found in Robotics News & Content, with a score of 18.00

…face.” Five critical geometries and dimensions used in the manufacturing of N95 masks will be made available to challenge participants for them to develop up to three masks. Submissions will be accepted until 11:59 p.m. on Sunday, April 26, with five designs going to the VA for fast track review and testing, and the top design(s) being announced on May 11, 2020. Interested participants can find more information here. Challenge America and VHA Innovation Ecosystem COVID-19 Makers Challenge: April 25 - May 3, 2020 America Makes is proud to promote the COVID-19 Makers Challenge, an event being hosted jointly by…