Editors’ Picks

Found in Robotics News & Content, with a score of 6.84

…company added that the N-220 can automate assembly, spot welding, packaging, and materials handling operations, as well as continuous process applications such as 3D printing and gluing. Comau claimed that these characteristics “deliver significant ease of use, straightforward integration, and faster post-installation maintenance while ensuring precision, flexibility, repeatability, and minimum backlash.” Comau looks to new markets Comau said its latest robot will offer “new levels of quality and supply chain flexibility in addition to cost-effective operation, as required by today’s high-growth market segments.” Since the 1970s, the company has built robotics applications for the automotive industry. Comau said the flexible…

Found in Robotics News & Content, with a score of 26.90

…One task that robots are doing more of is welding. April is National Welding Month. In the past, welding was often thought of as a job that would be difficult to automate. However, advancements in artificial intelligence, hardware engineering, and motion control are allowing robots to take on harder tasks. Today, robotic welding reportedly accounts for accounts for 29% of all robotics applications. Innovations in industrial and collaborative robots have helped the technology grow in response to demand. Welding workforce is aging The welding industry faces an aging workforce and a persistently slow trickle of new talent. In fact, less…

Found in Robotics White Papers & Archives, with a score of 20.01

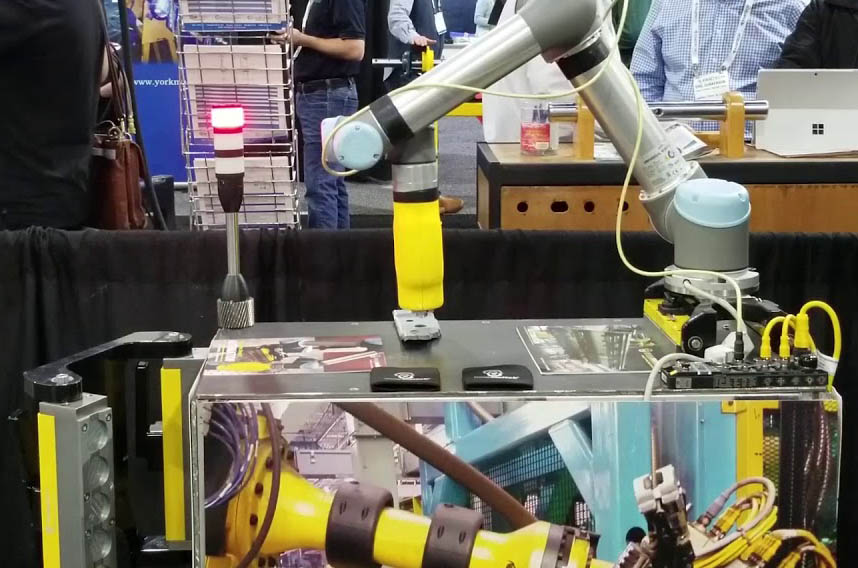

…changing how tasks such as machine tending, packaging, and welding are done. However, many small and midsize enterprises (SMEs) are reluctant to invest in systems for high-mix, low-volume applications. Integrators must evaluate the latest sensors, software, and end effectors for different use cases. In addition, researchers, integrators, and end users must consider the level of interaction with human co-workers, environmental conditions, and the safety of different payloads. In this Special Focus Issue, we consider how cobots have become a fast-growing segment of automation and how suppliers are turning their focus to specific applications. This free download covers the following: How…

Found in Robotics News & Content, with a score of 10.61

…parts for the metalworking industry or heavy lifting in the food-production sector. The seventh axis also enables continuous dispensing, welding, and material removal applications, regardless of access angle, without the need to reorient the arm, said Kassow.

Found in Robotics News & Content, with a score of 9.15

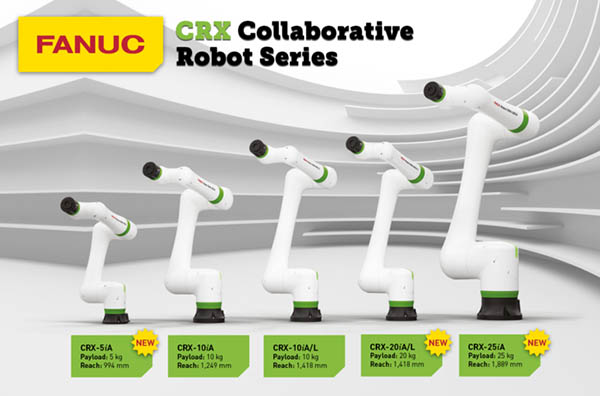

…unloading, packing, palletizing, vision-guided pick and place, sanding, and welding. The CRX robots can detect external forces in the workspace, stopping safely when making contact with a person or object. This technology allows the cobots to work safely alongside people without the need for expensive guarding. FANUC said its new CRX-5iA, CRX-20iA/L and CRX-25iA collaborative robots can handle payloads of 5, 20, and 25 kg (11, 44, and 55.1 lb.), respectively. They join its existing CRX-10iA and CRX-10iA/L models, which have 10 kg (22 lb.) payload and a reach of 1,249 and 1,418 mm (49.1 and 16.4 in.), respectively. The…

Found in Robotics News & Content, with a score of 5.75

…variation to activate appropriate responses. For product defects, a welding system with machine vision can support automated feedback and correction in real time, allowing the correction or remanufacturing of high-value parts such as those found in aerospace applications. A U.K. automotive fabric manufacturer uses such vision systems from Shelton Vision for real-time fabric inspection. Manual inspection is impossible because of the speed of fabric throughput and the different lighting required for identifying specific defects. Automated vision systems use all lighting conditions to identify every possible defect to a range of subtlety impossible by manual means. Defects are graded, classified, and…

Found in Robotics News & Content, with a score of 12.80

…or applications growing in popularity include machine tending and welding. Coupled with the labor shortage and an aging workforce, more and more businesses are starting to see the value of industrial automation. Top shops around the world Many of the top industrial automation providers are based in Asia or Europe, rather than in North America. Some examples include Zurich, Switzerland-based ABB Group and Kitakyushu, Japan-based Yaskawa. They are big companies with employees ranging in the thousands, and each has U.S. offices. The biggest robotics vendors have billions of dollars in annual revenue. As these companies get bigger, so too does…

Found in Robotics News & Content, with a score of 11.90

…of collaborative arms, as of late, has been arc welding, said Joe Campbell, senior manager of strategic marketing and application development at Universal Robots. Arc welding involves connecting pieces of metal electrically and is often used by metal fabricators. “In our world, it’s three times bigger than it was a couple of years ago,” he told Robotics 24/7. “It’s actually a little over 6% of our total volume. That’s new, and it’s continuing to grow every month.” Universal Robots recently reported a record annual revenue of over $311 million, up 41% from 2020 and 23% from 2019. While Universal Robots…

Found in Robotics News & Content, with a score of 8.69

…apply to different tasks, such as machine tending or welding. The global market for cobots will grow from $590 million in 2020 to $1.9 billion by 2030 at a compound annual growth rate (CAGR) of 12.3%, predicted Research and Markets. Mordor Intelligence was similarly bullish, forecasting a CAGR of 18.37%, from $668.3 million in 2020 to $1.8 billion in 2026. Universal Robots claimed that it introduced “the world's first commercially viable” collaborative robot in 2008. Since then, the company has installed more than 50,000 cobots worldwide, representing a fast-growing niche in industrial automation. Universal Robots' product portfolio now includes the…

Found in Robotics News & Content, with a score of 9.79

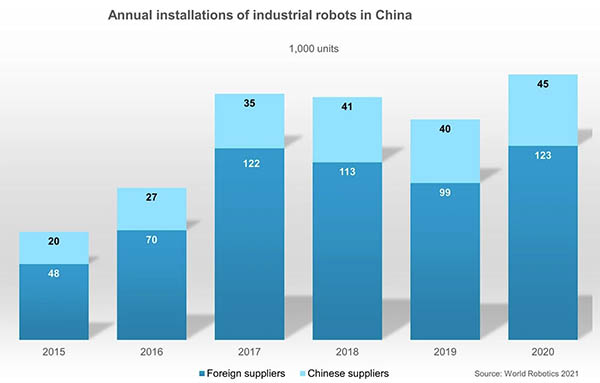

…2020: No.1 Shares of total supply: Handling operations 42%, welding 21%, electrical/electronics industry 37%, automotive industry 16% Stock of operational robots About 943,200 units, 21% higher than in 2019 CAGR from 2015 to 2020: +30% Global ranking 2020: No. 1 China plans to lead automation race Foreign robot manufacturers are the main suppliers in China's race to automation, with a combined market share of 73%, said the IFR. Although there has some volatility in the past eight years, this share has been constant, the organization noted. In 2020, the installations of robots from abroad—mainly imported from Japan, South Korea, and…

Found in Robotics News & Content, with a score of 7.63

…mm in thickness, according to the company. In resistance spot-welding applications, E-Series units provide single-sided gripping technology, eliminating the need for clamps, said Festo. With clamps removed, the spot weld gun is provided simpler access to the product. With a rapid on/off actuation time of 250 milliseconds, the E-Series can lower cycle time in comparison with clamps, said Festo. Magswitch said its E-Series grippers can be used in many other applications, including automotive assembly, white goods manufacturing, heavy industrial manufacturing, electronic assembly, bin picking, measuring, checking, ergonomic lift-assist, and collaborative cells. Novel uses for magnetic gripping Bond gave two examples…

Found in Robotics News & Content, with a score of 10.65

…top. One vertical that's really moving fast is robotic welding. A few years ago, a shop wouldn't consider a cobot, but it's now our fastest-growing vertical because of the versatility of our robots. Some partners are really being innovative, and smart OEMs are developing standardized solutions and then helping customers with the last 10% of whatever they need to do. With open APIs [application programming interfaces], it's easy to do something specific, like a welding deployment program in the U.S. or Europe. Another cobot application that's really getting traction is screwdriving. It sounds simple, but you have to be very…