Editors’ Picks

Found in Robotics News & Content, with a score of 9.93

…robots are perfect for a wide range of arc welding, handling, food & beverage and general assembly applications, in addition to foundry, automotive and battery manufacturing processes. Further benefits include improved access to small spaces, protected cables to avoid damage and reduce the risk of contamination in sensitive environments, integrated arc and gigabit dressings, and multiple mounting positions to save space without sacrificing performance. Another way Comau is reducing barriers to automation is by making the deployment and management of advanced robotic products increasingly more intuitive. This includes the intelligent programming paradigms found within its robot control software. For example,…

Found in Robotics News & Content, with a score of 9.91

…automation in manufacturing, for applications such as 3D printing, welding, and inspection, raised more than $140 million last month, in comparison with $219 million reported in June. Note that many companies did not announce the amounts of their transactions. Aerial drone businesses made at least $96 million in deals in July 2021 for use in cleaning, deliveries, farming, and security. Other industries represented in transactions tracked by Robotics 24/7 included defense/military, food preparation, and marine/energy. Merger and acquisition activity picked up, with 26 last month in comparison with seven in June, but only a few involving special-purpose acquisition companies (SPACs).…

Found in Robotics News & Content, with a score of 9.89

…company said the cobot's seventh axis enables continuous dispensing, welding, and material-removal applications regardless of access angle and without the need to reorient the arm, which allows for a smaller footprint and higher productivity. “Automation with conventional 6-axis robots would not have been possible in this case,” says Ingo Rathmann, managing director of Project Automation & Consulting GmbH. “Since it can reach around corners, the 7-axis KR1018 can be used in confined spaces.” The company said the cobot’s easy-to-use interface and plug-and-play nature make it accessible to small- and medium-sized enterprises (SMEs) without robot engineers. Dieter Pletscher, global sales manager…

Found in Robotics News & Content, with a score of 9.88

…efficiency, and applications for other materials and processes. Rapid Welding of Thermoplastic Composite Structure Source: Raythenon Technologies Principal Investigator: Raytheon Technologies Research Center Project Team: Carnegie Mellon University, Wason Technology LLC, and Collins Aerospace Project Description: Lightweight carbon fiber reinforced thermoplastic composites (CF-TPCs) are internationally recognized as a material capable of meeting the future aerospace market high-rate demands and providing sustainability benefits. One key contributor to the rapid manufacturing rate of CF-TPCs is its capability to be welded instead of using traditional time-consuming adhesive bonding and or mechanical fastening. Currently, three heat generation methods dominate the application and development of…

Found in Robotics News & Content, with a score of 9.86

…reach and a repeatability of +/- 0.03 millimeters, about 0.001 inches. The S-Family can be used for automated arc welding, foundry, automotive, and electric vehicle (EV) battery manufacturing processes, food and beverage handling, and general assembly applications. Characterized by their historical red robot design, Comau said the robots also reflect its dedication to making automation more accessible to diverse and non-automotive industries.

Found in Robotics News & Content, with a score of 9.79

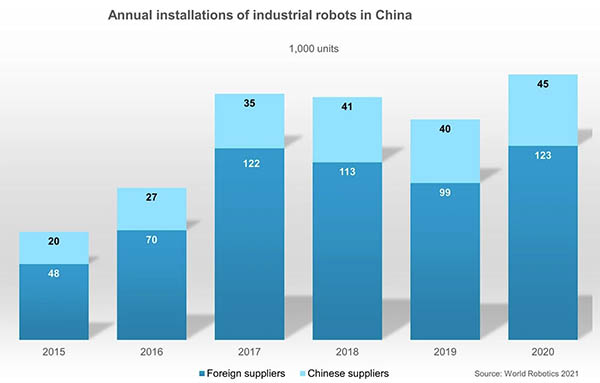

…2020: No.1 Shares of total supply: Handling operations 42%, welding 21%, electrical/electronics industry 37%, automotive industry 16% Stock of operational robots About 943,200 units, 21% higher than in 2019 CAGR from 2015 to 2020: +30% Global ranking 2020: No. 1 China plans to lead automation race Foreign robot manufacturers are the main suppliers in China's race to automation, with a combined market share of 73%, said the IFR. Although there has some volatility in the past eight years, this share has been constant, the organization noted. In 2020, the installations of robots from abroad—mainly imported from Japan, South Korea, and…

Found in Robotics News & Content, with a score of 9.78

…revenue of $83 million, which is up 8% from last year. The company said one particular growing application is welding. The company said it has also increased its revenue from original equipment manufacturer [OEM] channels.

Found in Robotics News & Content, with a score of 9.72

…attendees of our webcasts, there was strong interest in robots that worked well with people, including cobot arms in welding, goods-to-person systems paired with automated storage and retrieval systems (ASRS), and collaborative mobile robots such as those from 6 River Systems or Locus Robotics. Emerging teleoperation tools and software to manage growing robot fleets also did well. Check out the slideshow at right (below on mobile) to see Robotics 24/7’s top 10 robotics trends for 2022! Let us know what you think on LinkedIn. Editor's note: Eugene Demaitre and Cesareo Contreras make up the editorial staff of Robotics 24/7.

Found in Robotics News & Content, with a score of 9.67

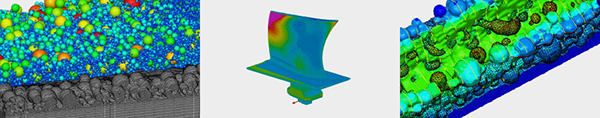

…long history with process simulation for metal manufacturing, including welding, casting and sheet metal forming. ESI Group adds that its AM solution is intended for process and manufacturing engineering departments as well as 3D printing bureaus seeking “first-time-right” prints, shortened time frames and fewer associated costs. ESI Additive Manufacturing supports manufacturers of 3D printed metallic parts in achieving greater productivity, while providing key information on final part quality. Image supplied by ESI Group and courtesy of Volum-e. As detailed on the ESI Group website, the ESI Additive Manufacturing suite offers computational modules for: process window pre-scanning tool; powder coating; melt…

Found in Robotics News & Content, with a score of 9.64

…globally. The company provides systems for applications including arc welding, assembly, coating, dispensing, material handling, material cutting, material removal, packaging, palletizing, spot welding, and clinical laboratory specimen processing. Rapid Robotics also works with Universal Robots Rapid Robotics last week announced that Universal Robots A/S will supply collaborative robots for Rapid's deployment of workcells across North America. The companies said this will enable them to serve more customers and maintain the rapid deployment times they've come to expect, even as Rapid Robotics expands its U.S. footprint. “As the number of unfilled, critical manufacturing roles increases and global economic uncertainty continues to…

Found in Robotics News & Content, with a score of 9.58

…its Hiroshima plant to deliver Mazda door panels to welding cells as part of a mission-critical process. The OTTO materials handling platform allowed HIROTEC to easily reconfigure its process to improve material movement efficiency and increase throughput. By installing the three OTTO self-driving vehicles, HIROTEC was able to eliminate the need for eight legacy Autonomous Guided Vehicles (AGVs). This is the second deployment of OTTOs within HIROTEC, they were first deployed at HIROTEC AMERICAS in 2017 to automate spare parts production. “Altech has a proud history of providing high-quality technology products and services to our customers,” said Hidehiko Suyama, executive…

Found in Robotics News & Content, with a score of 9.53

…anything from bin picking and heavy-load palletizing to ship welding. This variety is reflected in the UR Academy, which offers a range of courses ranging from virtual e-learning to in-depth and in-person classroom training. Universal Robots has 119 training centers around the world, with more opening soon. “No matter the task or the size of your company, you can find relevant training that can help you become even more successful with your automation,” said Vahl. “And we can see it works—customers who do take training with us are ultimately more successful and confident.” In addition, The Odense, Denmark-based vendor noted…