Editors’ Picks

Found in Robotics News & Content, with a score of 25.69

…delivers a smooth and automated workflow from design to manufacturing for digital and traditional manufacturers. ParaMatters 4.0 automatically generates ready-to-manufacture, high-performance, lightweighted structures for aerospace, automotive and other applications. ParaMatters CogniCAD 4.0 gives engineers and designers the flexibility to generate effective designs using a wide range of manufacturing options, including the use of additive manufacturing, 3-axis and 5-axis CNC milling, and investment and die casting. Version 4.0 provides more robust and faster solvers that enhance vibration and stress constraints design with more control over geometry and manufacturing, like multi-plane symmetry constraints and accurate feature size. It offers a new advanced…

Found in Robotics News & Content, with a score of 19.37

6K and 6K Additive, a developer of microwave plasma technology for the production of advanced materials, has been awarded a Phase ll SBIR program from the Defense Logistics Agency (DLA), following the success of its Phase I. The Phase II program supports the development and commercialization of a domestic and commercially scalable supply chain for high-performance metal powders from scrap sources. Using 6K's UniMelt microwave plasma platfrom the program will demonstrate 6K's capability to source, process and reclaim nickel superalloy scrap components, shop scrap, and used powders for conversion into aerospace grade powders. The new powders will be used to…

Found in Robotics News & Content, with a score of 15.35

…critical public health and infrastructure needs and to support manufacturing as it mobilizes in response to COVID-19. MxD’s three CARES Act-funded programs will focus on supply chain resiliency and transparency, rapid and secure medical device deployment, and pharmaceutical industry production optimization. “We did not have a pandemic in mind as we built our expertise and strategy—but with our focus on supply chain and cybersecurity issues, MxD was made for this moment, ” says MxD CEO Chandra Brown. “Our programs support both immediate and long-term efforts to address critical shortages, develop capacity for response among manufacturers, and secure the industry during…

Found in Robotics News & Content, with a score of 25.51

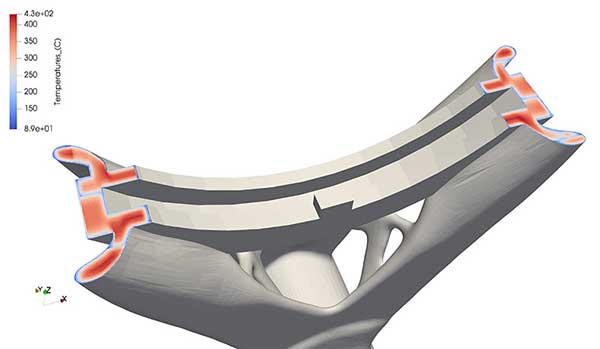

…parts. The new workflow teams EOS' metal systems for additive manufacturing with Ansys simulation solutions—equipping AM engineers to develop precise parts, improve productivity, slash production time and deliver new products faster, the companies report. The new collaboration advances interoperability between EOS and Ansys technologies. As a member of the EOS Developer Network, Ansys will enhance user AM processes via Ansys simulations and expedite printing by sending jobs directly to EOS' 3D printing systems. Additionally, to enhance simulation fidelity, Ansys simulations integrate EOS-specific data by leveraging EOS' open-source application program interfaces. This integration will help improve part geometries by predicting and…

Found in Robotics News & Content, with a score of 11.99

…project from Department of Defense (DoD) to develop an Additive Manufacturing (AM) process capable of mass producing Cobalt-free hardmetals, developed by the U.S. Army. The company’s Production System with Single Pass Jetting (SPJ), an AM technology developed by Desktop Metal, will mass manufacture complex shaped Co-free hardmetal parts without tooling and is expected to lead to the development of a dual-use technology with numerous applications in DoD as well as in the civilian sector. This new process has the potential to change the landscape of the carbide hardmetals market which is projected to grow to $24 billion by 2024 and…

Found in Robotics News & Content, with a score of 16.39

…economies shut down and fluctuating demand brought logistics and manufacturing to a screeching halt. One bright spot in the manufacturing and supply chain upheaval is additive manufacturing, which is fast emerging as an alternative way to produce key components at a local site while keeping the flow of goods in motion and the factory floor cycle intact. Strategic use of AM, experts say, can help manufacturers significantly reduce costs and transportation time while mitigating supply chain risks today, in the midst of the pandemic, and in the future as things start to normalize. That was the topic of a recent…

Found in Robotics News & Content, with a score of 29.73

…along with industry experts showcased the ability of digital manufacturing to transform industries. Underpinning the event was a new HP study delivering insights on digital manufacturing technologies and trends such as industrial 3D printing. HP’s Summit featured discussions with executives from Additive Integrity, Decathlon, Forecast3D, IDC, Nissan, SOLIZE Products, the World Economic Forum and more. Surveying thousands of manufacturing executives across the globe, HP’s Digital Manufacturing Trend Report finds that companies are investing in advanced 3D printing solutions that provide the agility, speed and flexibility necessary. A key insight from the global manufacturing industry is that regardless of sector or…

Found in Robotics News & Content, with a score of 32.75

The National Center for Defense Manufacturing and Machining (NCDMM) and Center Street Technologies (CST) announce the award of more than $9.4M in funding from the Air Force Research Laboratory (AFRL), Materials and Manufacturing Directorate, Manufacturing and Industrial Base Technology Division for a joint, two-year effort to support the Massive Area Additive Manufacturing (MAAM) Program. The announcement was made by U.S. Rep. Tim Ryan (OH-13) at CST’s Youngstown facility. The funding was part of the FY 2020 federal appropriations bill and spearheaded by Congressman Ryan, who sits on the Defense Subcommittee of the U.S. House Appropriations Committee. Furthering the MAAM technology…

Found in Robotics News & Content, with a score of 12.34

Two startups, pioneering solutions in the additive manufacturing and blockchain technology arenas, are teaming up to offer an offering aimed at delivering trust to a new generation of on-demand spare parts produced as part of a digital supply chain. Data Gumbo, the provider of the GumboNet massively interconnected blockchain network, is working on a pilot project with Fieldmade, an Oslo, Norway-based company aiming to empower next-generation supply chains with on-demand production of spare parts using AM capabilities. Together, the partners are trying to shake up the way aerospace and defense and oil & gas supply chains have operated for the…

Found in Robotics News & Content, with a score of 41.10

…2:00 PM ET/11:00 AM PT During the COVID-related shutdowns, Additive Manufacturing (AM) or 3D printing stepped in to fill the gaps resulting from suspended factory operations, proving it is more than a rapid prototyping technology. In this episode, panelists put AM on the hot seat to decide if it’s mature enough to become a means of mass-production. Moderated by a DE Senior Editor Kenneth Wong, webinar panelists will discuss: Volumes and shapes ideally suited for AM; Onsite printing vs. on-demand printing for a fee; The role of simulation in AM. Our presentation will be followed by a LIVE Q&A session.…

Found in Robotics News & Content, with a score of 12.44

…in the shortest amount of time, and the ever-evolving additive technology from Stratasys gives us confidence in our approach.” Team Penske and Stratasys have worked together through five championships and more than 70 race wins since their relationship started in 2017. In that time, Team Penske has gone from two Stratasys 3D printers to four. The company now has three FDM 3D printers supporting advanced materials—a Stratasys F900, Fortus 450mc and Stratasys F370—primarily for tooling, fixtures and end-use parts for cars. The team also has one PolyJet Technology-based J750 3D Printer for prototyping. All are installed at the Team Penske…

Found in Robotics News & Content, with a score of 41.08

…Nexa3D have announced a collaboration designed to bring Nexa3D’s additive manufacturing production systems up to full Industry 4.0 preparedness. This partnership highlights both companies’ commitment to help additive manufacturing prepare for Industry 4.0 with collaborations, open architecture and predictive serviceability. Having worked side by side with automotive, aerospace, medical and industrial customers, Siemens and Nexa3D have worked to combine connectivity, digital twin sensing and data acquisition to deliver predictive maintenance, process monitoring and print optimization to deliver polymer additive manufacturing solutions at scale on the factory floor, the companies report. Under this collaboration, Nexa3D’s entire Quantum Laser Sintering (QLS) product…