Editors’ Picks

Found in Robotics News & Content, with a score of 12.60

…the MakerBot survey found 93% of respondents reliant on plastics material for the most part followed by resins (25%), composites (14%), metals (7%), and biomaterials (7%). While the report shows that 3D printing is still heavily used for prototyping and modeling, companies are looking for materials that offer high strength and high temperature resistance for end-use applications such as jigs, fixtures, and robotic end effectors, Veisz says. Recent material launches like polycarbonate materials, available through MakerBot LABS, and nylon 12 carbon fiber have been a welcome addition to MakerBot’s METHOD platform for these demanding applications that go beyond prototyping use…

Found in Robotics News & Content, with a score of 6.28

…Extension Partnership, Kronos, Ceridian and Plex; State Sponsors Ohio MEP Network and Ohio Manufacturers' Association; and Industry Sponsors The Plastics Industry Association and Alliance for Automotive Innovation. Additional sponsors include Stanley Black & Decker and Marvin. Sources: Press materials received from the company and additional information gleaned from the company’s website.

Found in Robotics News & Content, with a score of 8.05

…printers in their repertoire, while 27% use SLA technology. Plastics (93%) and resins (25%) were the main materials used. Costs and technical expertise are major barriers to implementing 3D printing. 53% of respondents say that lack of budget is preventing them from fully using 3D printing, while 29% cite lack of technical expertise. Respondents expect the technology, materials and applications to develop over the next 3 to 5 years. A total of 61% of respondents expect more materials to emerge, while 58% expect the cost of using the technology to decrease. “We are pleased to release the MakerBot 3D Printing…

Found in Robotics News & Content, with a score of 5.64

…the tremendous potential to manufacture parts—and vehicles—in ways previously not considered possible. Marcel Spiegler is director, Customer Innovation Center, Plastics, 3D Systems.

Found in Robotics News & Content, with a score of 6.44

…more than 100 parts, 50 of them unique and plastic, to continuously adjust the pressure of the drive motor on the tire in response to sensored slippage, which optimizes performance regardless of road or weather conditions, officials say. ShareRoller initially opted to outsource parts production, but found it repeatedly faced challenges with part strength and surface quality. There were also long lead times and minimum order requirements, which made it difficult to iterate designs and produce prototypes, Guida explains. In addition, there is enormous part diversity with the OneMotor as it’s designed to attach to any number of bikes and…

Found in Robotics News & Content, with a score of 13.20

…about 50 industrial systems that work with metals and plastics. Another 50 systems are in operation at production sites around the world. In 2016, BMW i Ventures – the venture capital arm of the BMW Group – invested in the Silicon Valley-based company Carbon. Further investments were made in 2017, when the BMW Group became involved with Desktop Metal, That same year, BMW i Ventures invested in the U.S. start-up Xometry, a platform for on-demand manufacturing. BMW's latest investment was in the German start-up ELISE, which allows engineers to produce component DNA containing all the technical requirements for a part,…

Found in Robotics News & Content, with a score of 2.56

…for fever and to provide workers with masks and plastic face shields. Welcome to the post-COVID-19 industrial workplace While companies are wrestling with the question of when to re-open shuttered factories and distribution centers that were not deemed essential, the even bigger question is how to operate those facilities going forward. A very narrow aisle could take on a whole new meaning. Our industry has always looked for solutions to operate in an efficient and cost-effective way; now, it will also struggle with new issues related to preventing the spread of a virus - either COVID-19 or whatever is around…

Found in Robotics News & Content, with a score of 6.13

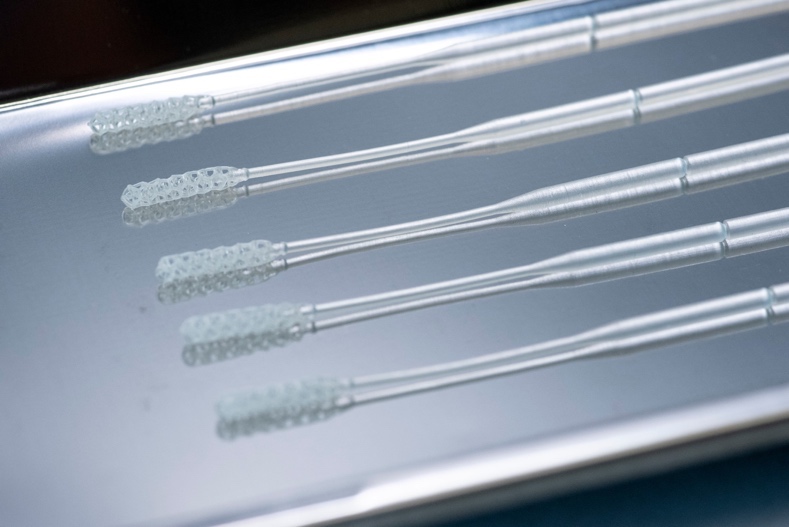

…Medical LLC. The winning design consisted of a single plastic material from tip to tip with a lattice structure to collect a sample at one end as opposed to traditional cotton swabs found in stores for consumer use, which have woven fiber at the tip. “Given that it’s only using one material, 3D printing is perfect for rapid output,” Oland explained. Dr. Gabriel Oland is leading the charge to 3D print nasal swabs to solve shortages at UCLA Health. Image Courtesy of UCLA Health The team was granted permission from the FDA to use the design, and the UCLA Health…

Found in Robotics News & Content, with a score of 8.76

…some brainstorming, the team landed on a common clear plastic binder from Avery as the base for the mask. For rest of the face shields, the team is using FDM 3D printing technology. “It works like an advanced glue gun, melting down hard plastic and re-extruding it in a pattern, laying down layer by layer,” Perla says. “It is quick and we were able to stack prints to maximize our machines during off hours.” More recently, Makelab introduced a custom mask through a partnership with Bellus3D, which employs an app that uses iPhone's FaceID camera technology to 3D scan a…

Found in Robotics News & Content, with a score of 15.64

…partners, parts providers and customers including Extol, specializing in plastics engineering and innovation with industry leading plastic assembly technology, custom automation and engineering services; GKN Powder Metallurgy/Forecast 3D, a provider of advanced industrial 3D printing, short-run manufacturing and high-volume production; Henkel, high-impact adhesives and engineering solutions provider; Oechsler; and Prototal, one of Europe’s parts manufacturers. New Professional Services, Expanded Alliances In additional news, HP announced new and expanded 3D Professional Services offerings and industrial alliances, including: HP 3D Professional Services: HP is unveiling a variety of new professional services capabilities including design optimization for breakthrough applications, manufacturing process streamlining to…

Found in Robotics News & Content, with a score of 10.69

…a sterile chamber around a 3D printer where unsterilized plastic is brought into the chamber. The possibly contaminated plastic is sterilized by the printing process and packaged maintaining the sterile field. This system was initially designed for a U.S. government agency to allow sterile medical materials to be printed at locations where commonly used sterilization methods might not be possible. “Because this printer can create sterile materials, which are sterile from the inside out once produced, we are eliminating the need for hospitals to resterilize equipment before use,” says Lacaze. “At a time when efficiency and supplies are critical, we…

Found in Robotics News & Content, with a score of 2.74

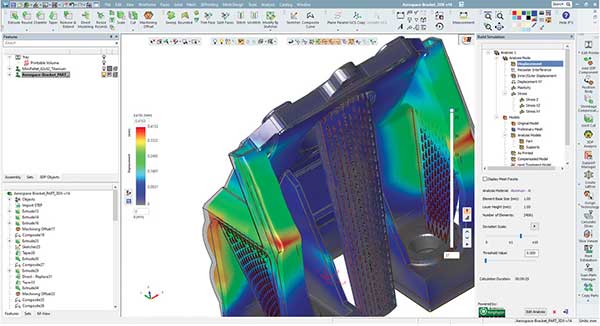

…advance. “There are more things you can do with plastic printing to compensate for the anticipated morphing or to fix it post-printing, but metal is much less forgiving,” Barkai says. “The harder the metal, the less forgiving it is. So printing in titanium, for example, gives you less room to work with than aluminum.” 3DXpert uses the Amphyon simulation kernel, developed by Additive Works. The same kernel is also used by Altair in its AM-targeted products. Described as “end-to-end fault prediction,” 3DXpert allows users to analyze and determine part orientation for the print job, design lattice fills and add support…