Editors’ Picks

What is a domestic robot? What roles will these machines play in the evolving smart home ecosystem? What can current technology do, and what tasks lie beyond its reach? To answer these questions and achieve a better understanding of these robots, engineers should start by dismissing most of their preconceptions about these machines. These robots are works in progress. In fact, developers have only just started to define the roles of the robot in the smart home. For appearance, there are probably as many forms as there are design teams. Although the designers’ imagination plays a part in defining these…

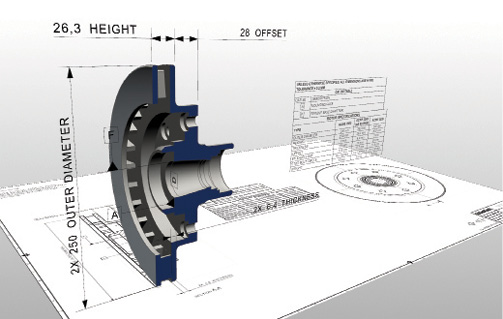

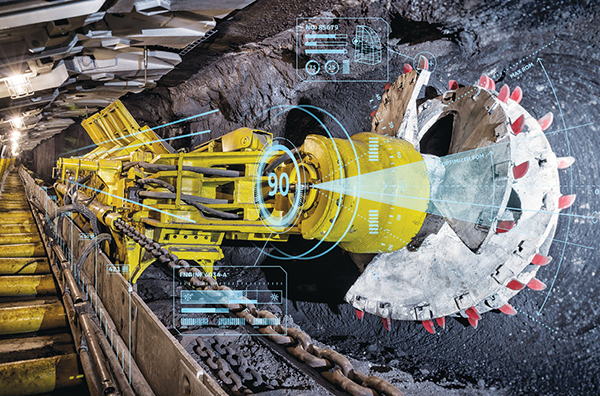

Developing machines for the Industrial Internet of Things (IIoT) requires engineers to bring the physical and digital worlds together on the shop floor to an extent rarely seen before. This involves incorporating a greater number and variety of components and subsystems into the machinery. Designers also must contend with more sophisticated issues, as well as accept the increased complexity of the design process. This means that engineers will have to work differently, adopting new design methodologies and tools to succeed (Fig. 1). Things Are Getting Complicated A close look at the IIoT reveals dynamic forces at work in the new…

The Internet of Things (IoT) presents design engineers with a new set of challenges. These range from the need for specialized operating systems to dealing with extreme constraints on power consumption and form factor. As inherent as its demand for new processor architectures, the IoT also requires designers to deploy fast, flexible and inexpensive memory to address the challenges for data-heavy use cases. As a result, development teams have begun turning to a form of non-volatile memory (NVM) called NAND flash. Developers usually relied on volatile memory for primary storage when the memory frequently interacted with a system-on-a-chip, a practice…

The Internet of Things (IoT) and edge computing have triggered the proliferation of connected devices, products that perform a rich assortment of functions and sport expanded capabilities. This, in turn, has increased the level of product design complexity engineers must tackle. The complexity becomes particularly evident when selecting processing resources for one of these devices. The problem is that engineers must not only meet a growing variety of seemingly conflicting design demands—like low-power operation and high performance—but they must do so using a bewildering assortment of processing options. Unfortunately, there are few easy answers. For processor architectures and technologies in…

The emergence of ubiquitous sensing and the Internet of Things (IoT) has sparked a migration of advanced processing, memory and communication resources to the network’s edge. In the process, these trends have caused a shift away from simple sensors to smart sensors, a move toward deploying greater intelligence at the data source. Yet the chain reaction does not stop there. Developers and users have started to push for analytics and the ability to perform more complex applications at the sensor level, due to the presence of more robust systems at the edge. This means giving smart sensors more muscle. Most…

Printed electronics developers have started launching the technology into the third dimension, throwing off the constraints of flat, 2D architectures to integrate electronics directly into a product’s geometry. Until recently, electronics companies designed and manufactured components, systems and layers in 2D. Then they finished off the lengthy process by performing steps like drilling, pressing and plating to connect the separate dies to create a multi-layer circuit board. When you say, “3D circuit,” people still think of stacked planar circuits, perhaps connected vertically using vias. The inability to shake off the 2D mindset has slowed the evolution of printed electronics technology,…

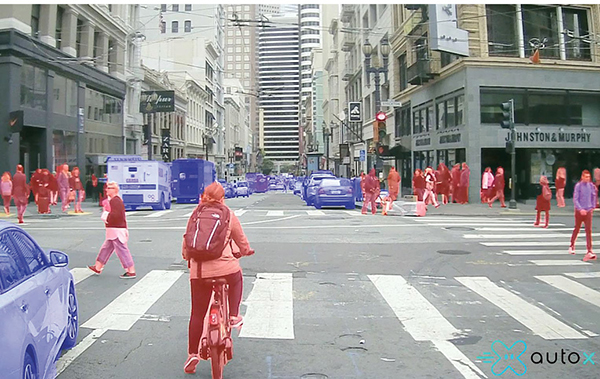

Deep learning (DL)—one of the newest trends in artificial intelligence—has driven remarkable progress in the development of autonomous driving systems, but the driverless car has a long way to go before it crosses the finish line. One factor holding the technology back is its need for massive amounts of data for training, testing and validation. The growing fleet of driverless test vehicles is helping to meet this requirement. Industry experts estimate that just one of these vehicles can generate as much as 10TB of data per hour. But as astounding as it may sound, it’s not enough. Research teams need…

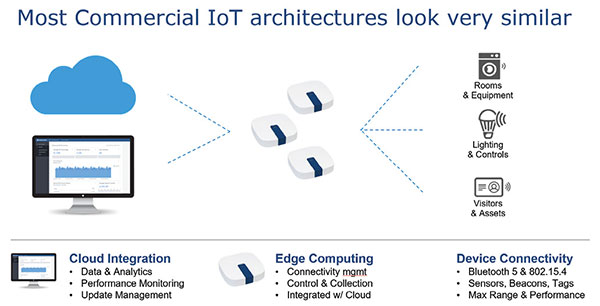

The internet of things (IoT) has several faces. Some have become familiar to almost all segments of society, like wearables, while others claim notoriety only in specific markets, such as industrial IoT systems. But there is more to the IoT than these two sectors. Another face that is gaining attention is the commercial IoT. Related Coverage Connecting the Thread: 5G Connecting the Thread: Digital Twins Although developers of this technology use design techniques, architectures and subsystems found in the consumer and industrial domains, the commercial IoT poses design challenges that differ significantly from its counterparts, placing unique demands on design…

In recent years, design engineers have expended considerable time and resources to impart human-like senses into new products, with some notable successes. Natural language processing has helped develop intelligent virtual assistants that enable increasingly rich interaction between humans and machines. At the same time, computer vision has played an important role in bringing amazing applications to life, such as the autonomous car. Tom Kevan However, attempts to give devices the sense of touch have proven to be more elusive. Scientists and engineers have struggled to not only replicate our skin’s ability to precisely detect tactile information—like smoothness, hardness and pain—but…

Researchers at Vanderbilt University have developed a non-destructive evaluation process that promises to enhance manufacturers’ ability to assess the structural integrity of 3D-printed products. The new testing technique chips away at one of the chief obstacles keeping additive manufacturing (AM) from taking on more demanding applications in the automotive, aerospace and medical equipment industries. An interdisciplinary team of researchers at Vanderbilt University has developed a technique that uses the optical properties of gold nanoparticles to detect and quantify missing layers in 3D-printed products. By scanning light across the surface of a printed object, engineers can identify defects in that material.…