Editors’ Picks

Given the vast complexity and scope of autonomous vehicle development, it’s going to take a village to get new, self-driving cars to market. VSI Labs, which already collaborates with a variety of leaders on its VSI Labs Capability Demonstrator, is striking yet another partnership, this time with Siemens Digital Industries Software to advance development using digital twins. VSI Labs, which researches active safety and AV technologies, is partnering with Siemens, using its PAVE360 platform to create digital twin simulations for the validation and testing of all the processors, electronics, sensors, and systems that are powering the VSI Labs Capability Demonstrator.…

JAMADE’s Amazea breaks the mold for water sports innovation in various ways. The vehicle is an underwater scooter, which replicates a dolphin’s body ergonomics for faster movement, and it is also emissions-free with low noise operation—an attempt to minimize impact on the marine ecosystem. Another point of disruption: 75% of the Amazea—specifically, the scooter’s body and front parts—are produced with BigRep large-scale 3D printing technologies in contrast to using traditional casting or injection molding methods. Underwater scooter produced using BigRep's technologies. Image courtesy of JAMADE/BigRep. Large-scale additive manufacturing (AM), and the BigRep One printer in particular, fit the bill because…

ShareRoller is a NY-based start-up with a cool idea: Its OneMotor power system transforms standard push-pedal bikes and kick scooters into electric mobility solutions without having to purchase new gear. ShareRoller took its innovation a step further using 3D printing technology from HP to deliver highly customized parts more quickly and more cheaply, forgoing investment in costly tooling. At the same time, embracing 3D printing for production and prototyping opens up design freedom for ShareRoller engineers, helping them more easily iterate product designs and aiding in continuous improvement. “3D printing is an absolute game change for hardware engineering start-ups like…

What do you get when you combine a laser scanner with a robot capable of remote data capture? You get Trek, a fully autonomous 3D mobile scanning device capable of remotely monitoring the progress and condition of commercial construction projects or creating digital twins of a manufacturing floor, among emerging use cases. FARO, a leader in laser scanning technology, teamed up with robotics trailblazer Boston Dynamics on Trek, which combines the scanning speed and accuracy of the FARO Focus Laser Scanner with Spot, the quadruped robot capable of doing remote and autonomous data capture in challenging environments. Aimed initially at…

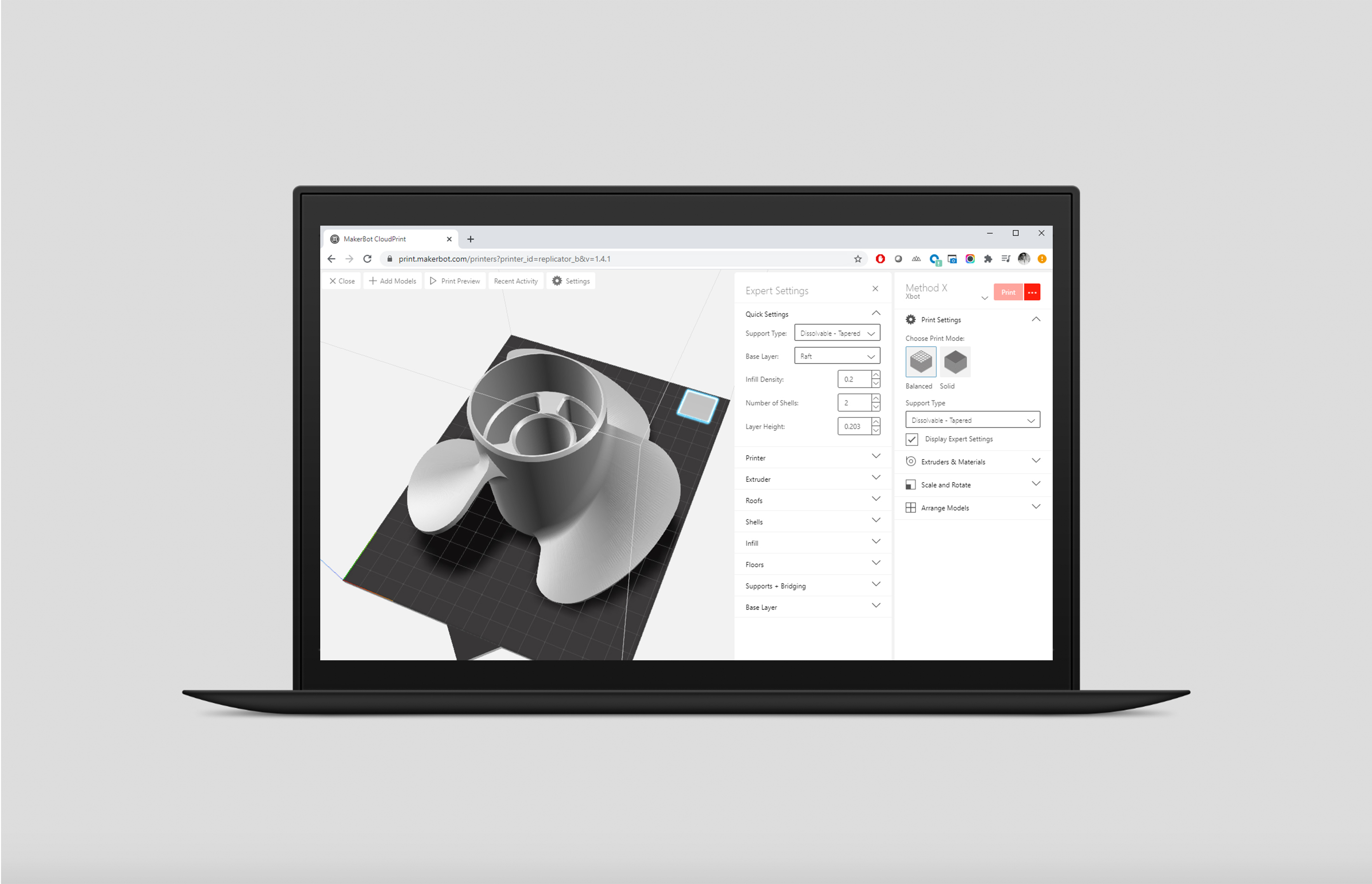

With engineering teams increasingly working remotely or from disparate locations, managing and monitoring 3D print jobs can be a challenge, taking time away from primary design responsibilities or becoming so burdensome that it eliminates 3D printing from the toolkit. MakerBot is seeking to address the complexities of managing 3D print jobs with a new cloud-based version of its 3D printing platform designed to provide a seamless workflow for teams working remotely or from off-site locations. The new MakerBot CloudPrint enables individual engineers or far flung teams to utilize 3D printers, including the METHOD industrial versions, collaboratively, working from a browser…

General Motors (GM) is shifting its multi-decade road trip in additive manufacturing into high gear with accelerated efforts to expand tooling and manufacturing applications, including for its latest government contract to make ventilators and personal protective equipment (PPE) in the battle against COVID-19. GM has leveraged 3D printing for prototyping applications for years—in fact, 75% of the parts in the 2020 Chevy Corvette prototype were 3D printed. Now, fresh off a commitment to add 17 new Stratasys FDM 3D printers, GM is expanding 3D printing into production-grade applications like tooling and parts manufacturing. Today, more than 700 GM employees are…

As 3D printing gains increasing support a feasible alternative to traditional manufacturing, it also creates opportunity for a wave of new cybersecurity risks, from theft of design intellectual property (IP) to malicious destruction of parts and planned system failures. 3D printing has been in the spotlight as the market incorporates new and more sophisticated offerings sporting novel printing technologies and advanced materials choices. At the same time, this next-generation of high-powered printers has been retooled to fit the needs of mainstream design and manufacturing engineers, from a cost and accessibility standpoint. The result has been increased adoption of 3D printing…

Siemens has coupled key pieces of its software and hardware technology to create a new solution designed to help manufacturers balance the need to ramp up production while maintaining employee safety as the economy opens back up in the wake of COVID-19 shutdowns. The solution pairs Siemens’ SIMATIC Real Time Locating Systems (RTLS) with its Xcelerator portfolio of engineering, operational, IT, IIoT, and cloud solutions to create a workplace distancing solution that helps minimize employee exposure risks while optimizing productivity. In what many are calling the “new normal” or “next normal,” companies are scrambling to figure out how to address…

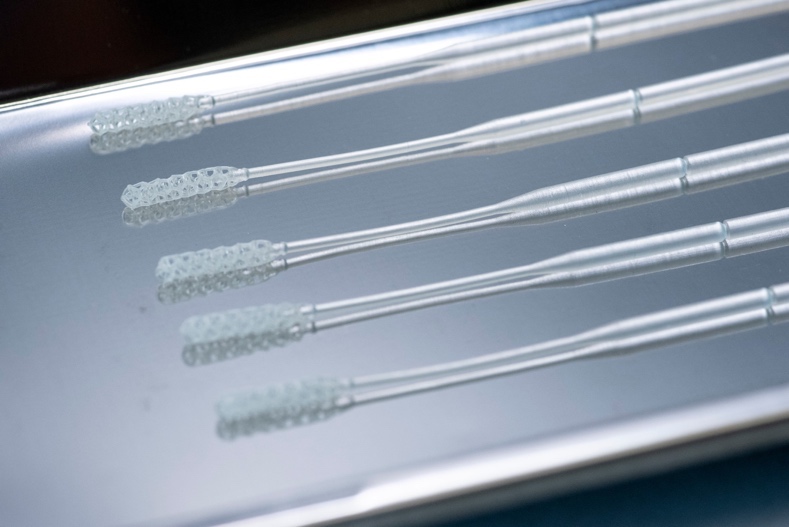

Testing remains one of the fundamental hurdles to wresting control over the COVID-19 outbreak. To help break the logjam, companies hailing from the 3D printing and medical research worlds are combining forces to innovate new solutions to address the shortage of nasal swabs. 3D printer manufacturer Stratasys is pooling resources with a lesser known 3D printer company to market and promote 3D printed nasopharyngeal (NP) swabs to healthcare providers and U.S. testing centers. Instead of leveraging its own 3D printer technology, Stratasys is lending its sales and marketing muscle and healthcare industry presence to start-up firm Origin, helping the firm…

One of the many laudable essential workers of the COVID-19 era is proving to be 3D printing technology, which is being harnessed in force to churn out face masks and face shields, all of which have been in short supply for the duration of the global pandemic. Across the world, 3D printing technology providers and service bureaus are teaming up with government agencies, hospitals, and corporate enterprises in myriad public-private partnerships to coordinate and build open-source medical supplies in response to COVID-19. For its part, the Food and Drug Administration (FDA) is facilitating public use of 3D printing technologies to…

Driven by the preferences of a younger generation, consumers are leading the push for more personalized products, putting pressure on design teams to deliver the goods while maintaining speed and flexibility in their engineering processes. Dassault Systèmes, in partnership with CITE Research, recently published the results of its CES 2020 survey on personalization, canvassing 3,000 consumers in the United States, China, and France to inquire about trends in personalization across the healthcare, mobility, and retail segments as well as home and city environments. The findings revealed a growing desire among consumers for personalization in products—a quarter of respondents, on average,…

As company officials describe it, the Inkbit 3D printer is a multi-material ink-jet platform with eyes and brain. In simple terms, the jetting-based additive manufacturing system employs machine vision and machine learning/artificial intelligence (AI) capabilities to learn the properties of materials, predict behavior, and adjust printing over time. The goal: High precision, multi-material production-grade output. The start-up company, spun out from MIT’s Computer Science and Artificial Intelligence Laboratory (CSAIL) in 2017, is based on research led by Professor Wojciech Matusik and intellectual property licensed from MIT. Inkbit saw reason to create a new platform for 3D printing because while they…