Editors’ Picks

Found in Robotics News & Content, with a score of 14.43

…previously impossible geometries. Its customers include Aerojet Rocketdyne, Chromalloy, Honeywell, LAM Research, and Raytheon Technologies. In March, VELO3D announced plans to merge with JAWS Spitfire Acquisition Corp. and become a public company. Metal printing pioneers build Vertex Vertex Manufacturing founders Greg Morris, Steve Rengers, and Tim Warden previously worked at metal printing supplier Morris Technologies Inc. (MTI). They are best known for their work with GE Aviation’s 3D-printed LEAP Engine fuel nozzle used in commercial aviation, said the company. In an industry with exacting standards for the safety and quality of manufactured parts, the nozzle was one of the first…

Found in Robotics News & Content, with a score of 67.98

VELO3D and Honeywell Aerospace, a user of additive manufacturing (AM) technologies with knowledge across various platforms and applications, have announced a partnership to qualify VELO3D’s Sapphire system as a manufacturing platform for 3D print production of aircraft components. The Sapphire system was selected for its capabilities for building complex geometries without the requirement of support structures. The VELO3D Sapphire system will be in Honeywell Aerospace’s Phoenix facility. The qualification process is underway and is focused on INCONEL, a nickel-based super alloy well suited for extreme temperatures. VELO3D will provide their expertise in developing suitable parameter sets for Honeywell Aerospace to…

Found in Robotics News & Content, with a score of 29.61

Honeywell Intelligrated & The Apparel Logistics Group Honeywell Intelligrated has partnered with The Apparel Logistics Group – a leading provider of third-party logistics (3PL) and order fulfillment services for apparel, footwear, and accessories – to more than triple its daily e-commerce order output by installing new automated material handling solutions. Honeywell’s technology and support services will help to: Increase productivity at the company’s shipping dock, maximizing uptime Expand e-commerce parcel shipping capabilities, which currently afford retailers one-day turnaround Ensure accuracy while expanding value-added service capacity, including returns management and order customization The Signed Honeywell Intelligrated & The Apparel Logistics Group…

Found in Robotics News & Content, with a score of 12.43

…engineering, Ford; Donald Godfrey, engineering fellow of additive manufacturing, Honeywell Aerospace; and Markus Seibold, VP additive manufacturing, gas and power, Siemens AG. RAPID+TCT panel on Trends in Additive Manufacturing included leaders from Ford, Honeywell Aerospace, Jabil and Siemens. Dulchinos kicked things off with an obstacle. “One of the challenges today is if you design for additive you don’t have a backup plan to go produce in a traditional manufacturing process. That’s problematic, because there isn’t really a rich supply chain today. We’re really big advocates around open systems, around having partnerships and ecosystems that come together to set standards and…

Found in Robotics News & Content, with a score of 10.93

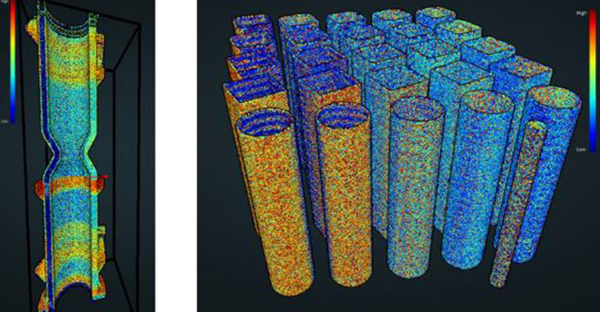

…shortly after news of a DARPA-funded research project at Honeywell Aerospace on the use of Sigma Labs technology as available in PrintRite3D. The study (“LPBF [Laser Powder Bed Fusion] Right the First Time—the Right Mix Between Modeling and Experiments” https://link.springer.com/article/10.1007/s40192-019-00133-8) was published in the journal Integrating Materials and Manufacturing Innovation. It describes the validation involved in manufacturing a challenging metal component. Sensors were used to develop a new in-process quality metric called thermal emission density (TED), used to monitor component quality with respect to porosity as the part was being built. The research paper concludes: “This work has demonstrated that…

Found in Robotics News & Content, with a score of 16.48

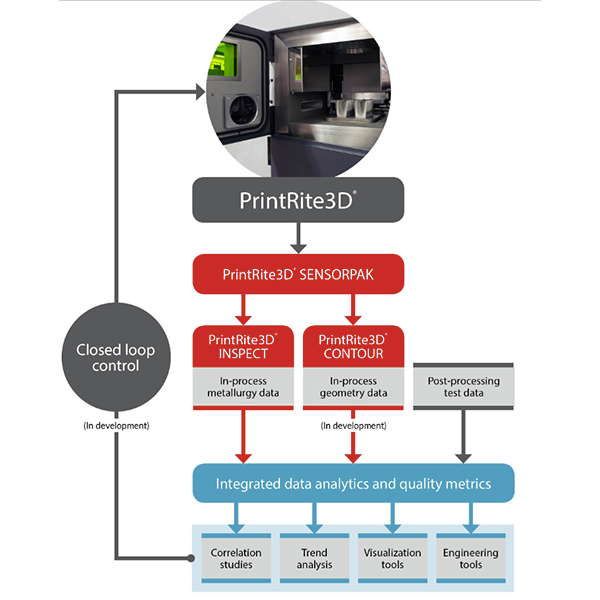

…validation of a challenging metal component being manufactured by Honeywell Aerospace using laser bed powder fusion. The conclusion: “This work has demonstrated that a combination of physics-based modeling and experimental verification and validation can enable early-stage identification and elimination of potential problems.” PrintRite3D is platform independent, it can work with most existing metal AM systems. Using it means you gain an independent third-party source for Quality Assurance. You can retrofit PrintRite3D to existing AM installations or integrate it into new purchases, and the platform is compatible with existing OEM supplied sensors. Here’s how the process works. The software modules acquire…

Found in Robotics News & Content, with a score of 24.57

…report highlights notable AM-related activities in many industries, including aerospace. The team collected insights from the likes of Airbus, Boeing, Honeywell Aerospace and United Technologies Corp. to gain perspective on using AM to produce end-use parts. These companies, along with BMW, Deutsche Bahn, FIT, Jabil, Oerlikon, UPS, the U.S. Marine Corps, and others shared emerging trends from their vantage points. Among the trends are knowledge and skills development, cyber security, post-process automation, materials development, partnerships and industry standards. New and expanded features of Wohlers Report 2019 include: Benefits and challenges of designing for AM, Listing of 107 early-stage investments valued…