Editors’ Picks

Found in Robotics White Papers & Archives, with a score of 13.91

…robotic equipment collects data on human movement to improve ergonomics. Technological advancements in data collection, analysis and connectivity allow organizations to harness the information already at their fingertips better than ever before. With robotics and automation generating mountains of valuable data for humans and neural networks to sift through, organizations can accurately monitor and track their inventory and workflows. When combined with generative AI analytics, robots can serve as mobile data platforms, informing decision-making and improving operational efficiency for commercial and industrial end users. In this Special Focus Issue Dexory delivers real-time visibility for warehouse operators Nokia AIMS automates inventory…

Found in Robotics News & Content, with a score of 13.75

…reflect the priorities of operational efficiency, operator productivity, and ergonomics, said Nedre Vats, Norway-based company. “Businesses today need to optimize their picking process if they are to meet evolving customer demands, but in order to achieve this, warehouses must be equipped with the tools that will enable their employees to work productively and safely,” said Carlos Fernandez, chief product officer at AutoStore. “This is why we're excited to offer FusionPort and FusionPort Staging, which will enable businesses to best serve their staff while leveraging the world-class technology that AutoStore is known for,” he said. FusionPort, FusionPort Staging designed for easy…

Found in Robotics News & Content, with a score of 13.36

…reports, and insights, honing in on aspects such as ergonomic risk analysis, trend analysis, and exosuit utilization. “The SafeLift exosuit development was informed through extended testing of human subjects where we collected biomechanics data in a lab environment” said Conor Walsh, scientific co-founder of Verve Motion. “It is exciting now that Verve Motion is making this same type of data available to workers and their organizations through Verve Logic so they can understand injury risk reduction and optimize the use of SafeLift for their operations.” Sensors embedded in the SafeLift exosuit collect 3D motion and force data while the suit…

Found in Robotics News & Content, with a score of 13.26

…a mandate to drive continuous improvements in safety and ergonomics. “In just about every major city where we have distribution centers, there is real competition for labor,” says Rodriguez. Put them together—the need for speed, quality, service and labor shortages—and “automation becomes a way to operate successfully within the context of these competing demands,” says Rodriguez. In fact, new demands may be changing the rules for justifying automation, at least when it comes to the traditional measure of return on investment, adds Rich Werner, vice president of physical flows for L’Oreal’s consumer products division. “ROI is still important, but the…

Found in Robotics News & Content, with a score of 12.96

…designers to miniaturize products as well as change the form of the overall electronics package, allowing more organic and ergonomic designs. Optomec Aerosol Jet 5X System. Image courtesy of Optomec. The Optomec Aerosol Jet 5X system supports five-axis of coordination motion with a 200x300x200 mm (x, y, z) print envelope and the ability to print features ranging from 10 microns to millimeters. Sources: Press materials received from the company and additional information gleaned from the company’s website.

Found in Robotics News & Content, with a score of 12.90

…3D representations of the infrastructure, plant, machinery, equipment, human ergonomics, safety information, robots, automated guided vehicles (AGVs), and detailed product and production simulations. These technologies will help FREYR to meet surging demand for high-density, cost-effective battery cells for stationary energy storage, electric mobility, and marine applications, said the companies. Amid growing worldwide sustainability initiatives and the rapid electrification of transportation, the battery industry will grow to $400 billion by 2030, projected McKinsey & Co. Battery cell manufacturing is a critical step in the battery value chain, with manufacturers investing billions of dollars in new battery-cell plants to meet this new…

Found in Robotics News & Content, with a score of 12.80

…that create safety challenges.” Investing in employee safety and ergonomics Suppliers report an increased focus on dock safety and ergonomics, particularly with regard to employees that unload floor-stacked containers and trailers. Employee turnover can be high in this area as well, since workers are required to use step stools or climb on boxes to reach items that are stacked above their heads. “Where much time, effort and capital is spent on the loading operation, warehouse management system and order picking side of the operation, the unloading operation generally requires employees to mainly perform manual labor as they hand stack boxes…

Found in Robotics News & Content, with a score of 12.63

…They include telematics and fleet software, operator assist and ergonomic features that use sensors, as well as motive power technology such as lithium-ion batteries that cut out battery-swap procedures. “Much of our truck technology today is centered around making the trucks we have smarter and more intuitive, both for the operators and the managers,” said John Slavik, senior manager of intelligent warehouse solutions at Raymond Corp. “This would be, for instance, technologies like telematics or real-time locating features.” “Just like our cars today, our customers want intelligence that provides more value than simply moving the vehicle from Point A to…

Found in Robotics News & Content, with a score of 12.24

…that uses robots moving goods between high-density storage and ergonomic stations. The system significantly shortens fulfillment times by automating highly manual tasks like walking and lifting heavy objects. acca international, and Exotec will collaborate to deliver a solution that meets PAL’s warehousing and shipping needs. acca international will provide fulfillment services to a warehouse that has adopted the Skypod system, aiming to effectively manage a distribution warehouse for clothing, everyday items, and other products from PAL Co., ltd. acca to support Skypod system customers Tokyo-based acca international, a third-party logistics (3PL) company, said it supports the functioning of e-commerce clothing…

Found in Robotics News & Content, with a score of 11.47

…goods-to-person picking,” he added. The company is also sharing a new, cross-platform software user interface specifically to improve operator ergonomics during human/machine interaction, and a remote service and troubleshooting package to help customers diagnose and resolve technical issues quickly. Additionally, KNAPP’s exhibit in Booth 4962 showcases cubing, scanning, dimensioning, measuring and weighing systems from new group member KHT. Modex 2016 is scheduled to be held April 4-7, 2016 in Atlanta’s Georgia World Conference Center. The tradeshow will showcase the latest manufacturing, distribution and supply chain solutions in the material handling and logistics industry. Modern’s complete Modex coverage.

Found in Robotics News & Content, with a score of 11.23

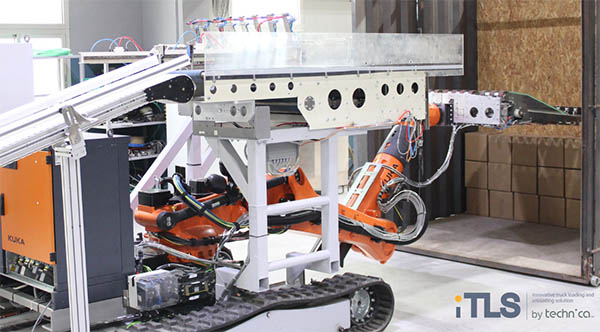

…of truck loading and unloading, compounded by poor user ergonomics for heavy loads, frequently results in low vehicle fill rates and high dock turn-around times. This creates inefficiencies at both ends of the warehouse and takes a toll on workers, which can increase accidents, noted GreyOrange. Technica said it delivers “innovative, customized, and high-quality solutions and turnkey lines” designed to help customers to improve their operational efficiency and increase their production capacity. The company has offices in Bickfaya, Lebanon; Warsaw, Poland; and Montreal, Quebec. Industry sectors served by Technica include food and beverage, chemicals, glass, plastic, dairy, pharmaceutical, home and…

Found in Robotics News & Content, with a score of 11.10

…gets them where they need to be, when they need to be there. The solution is based on an ergonomic headset, wearable mobile device and advanced software that utilizes “text-to-speech” and “speech-to-text” technology (currently available in 41 languages). By converting warehouse management system information to speech, Honeywell Voice provides audible instructions to warehouse operators — directing them to the next location and guiding them through the required tasks or steps to complete processes, such as picking, inventory replenishment, maintenance and repairs.