Editors’ Picks

Found in Robotics News & Content, with a score of 25.50

…The new HP 3D High Reusability PP, enabled by BASF, is a durable and chemically resistant material that has been qualified for HP’s production-grade 3D printing systems, and is ideal for customers in the automotive, consumer, industrial and medical sectors. HP also unveiled a new partnership with Oechsler, a global design and manufacturing player, to develop applications for both the new PP and HP’s broader materials portfolio, as well as new customer Cobra Golf for its Metal Jet 3D printing technology. Door defroster vent used in the ventilation system of automobiles. Printed with HP 3D HighReusability PP enabled by BASF.…

Found in Robotics News & Content, with a score of 55.02

…out of Harrison, Ohio, announces a distribution partnership with BASF 3D Printing Solutions (BASF 3DPS). CI’s high-temperature Small Area Additive Manufacturing (SAAM HT) machine will now offer BASF 3DPS’s ABS plastic, carbon fiber PET and recycled PET materials. Ultrafuse ABS is created from acrylonitrile, butadiene and styrene polymers. It has a strong, flexible and heat-resistant nature, according to the companies. It can be used for those looking to manufacture low-cost prototypes, or anyone who wants to create plastic products with ease. Ultrafuse PET CF15 from BASF 3DPS combines processability and low moisture uptake with strength and rigidity. With this PET…

Found in Robotics News & Content, with a score of 54.06

BASF New Business GmbH has formally agreed to acquire the online 3D printing service provider Sculpteo. The agreement was signed on November 14, 2019, and is expected to become effective in the next few weeks pending regulatory approval by the relevant authorities. The acquisition of the French 3D printing specialist based in Paris and San Francisco will enable BASF 3D Printing Solutions GmbH, a wholly-owned subsidiary of BASF New Business GmbH, to market and establish new industrial 3D printing materials more quickly. Sculpteo’s management team fully supports the acquisition and will remain in place to provide customers and partners with…

Found in Robotics News & Content, with a score of 35.15

BASF 3D Printing Solutions (B3DPS) will be exhibiting at Formnext 2019 sector show for additive-based manufacturing, with an expanded product range and a new brand presence. Sector specialists are invited to meet B3DPS specialists in person from November 19 through 22 at Booth D21, Hall 12.1 at the Frankfurt Trade Fair. With the introduction of its new Forward AM corporate brand, B3DPS continues to pursue its goal of driving industrial scalability as the next phase of additive-based manufacturing, the company says. “Forward” stands for future-oriented, leading-edge materials and technology, while “AM” stands for “additive manufacturing”. The new arrow-symbol brand logo…

Found in Robotics News & Content, with a score of 10.55

…inviting materials companies and resin suppliers such as DSM, BASF and others to develop high-performance resins in conjunction with Fortify material scientists and engineers. “We’ve achieved so much since our founding, and we’re eager to expand on our platform capabilities,” says Josh Martin, CEO and founder of Fortify. “With the support of our investors, we will focus on innovation, bring our technology to new partners, and grow our product offerings.” Fortify has experienced growth over the past year, doubling their team and securing new office space to accommodate the expansion. Notable hires include industry veteran Ben Arnold as VP Business…

Found in Robotics News & Content, with a score of 36.19

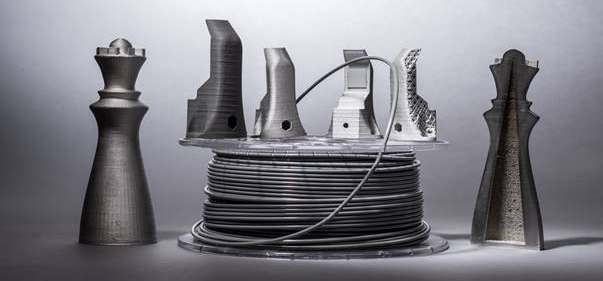

With Ultrafuse 316L, BASF 3D Printing Solutions launches a metal-polymer composite for fused filament fabrication (FFF). It enables the safe, simple, and cost-efficient production of fully metal parts for prototypes, metal tooling and functional metal parts in 3D printing, according to the company. After the subsequent industry-standard debinding and sintering, the final 3D printed part is 316L stainless steel. FFF refers to a 3D printing process in which parts are built up layer by layer from moldable material. Ultrafuse 316L, a metal filament with polymer content, uses the same process; first, a suitable 3D printer builds a part layer-by-layer, with…

Found in Robotics News & Content, with a score of 7.15

…grand opening included Siemens for software and factory processes; BASF and GKN for materials; Materialise and ZiggZagg for services; and Avid Product Development for design optimization. Disrupting Manufacturing Business Models Business model disruption was as much of a theme as any particular technology or partnership. “We are in this business to impact how manufacturing affects the whole business model,” says Schell. An example can be found in orthodontics. First Invisalign (a 3D Systems customer) used 3D printing to create custom braces sold through orthodontic offices, then SmileDirectClub (an HP customer) moved to a home delivery model, bypassing clinics altogether. When…

Found in Robotics News & Content, with a score of 11.61

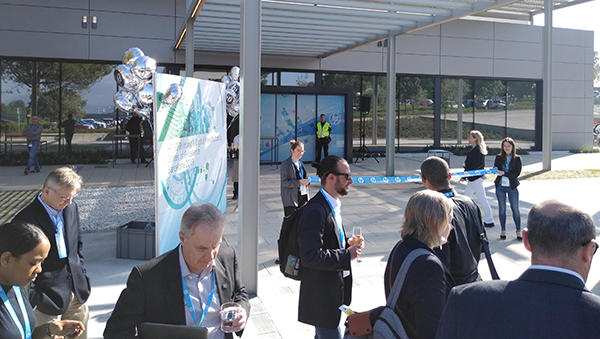

…development and end-to-end solutions for customers. Leaders such as BASF, GKN Metallurgy, Siemens, Volkswagen and others across the automotive, industrial, healthcare, and consumer goods sectors will continue collaborating with HP on new 3D printing and digital manufacturing innovations at the Center. The 3D Printing and Digital Manufacturing Center of Excellence design also reflects HP’s commitment to the environment by incorporating a photovoltaic canopy to provide 110kW of power, rain water reuse for irrigation and sanitary purposes, HVAC and natural light optimization, and eco-friendly construction materials with a goal of achieving a LEED (Leadership in Energy and Environmental Design) Certification. At…

Found in Robotics News & Content, with a score of 9.26

…Several dozen customers and partners of Materialise, including Siemens, BASF and Stratasys, along with the press, visited to get an insider’s look at what’s happening at the company’s Midwest location, in operation since 2009. Materialise, headquartered in Leuven, Belgium, also operates facilities in 17 other countries, and has another U.S. operation in nearby Ann Arbor. Materialise’s products include software, medical applications of 3D printing, and stereolithography (SLA) and selective laser sintering (SLS) 3D printers for manufacturing. The industries it servers span everything from aerospace, architecture, art and automotive to consumer goods, eyewear, healthcare, machinery and service bureaus/contract manufacturers. In Plymouth,…

Found in Robotics News & Content, with a score of 7.45

…HP’s new certified thermoplastic polyurethane (TPU), ULTRASINT developed by BASF, which is ideal for flexible and elastic parts. HP has gained certification as part of Materialise’s program to test and validate 3D printing technology as being fully compatible with Materialise Mimics and Mimics inPrint software. This certification allows medical professionals to use the HP Jet Fusion 580/380 3D printers, in combination with Mimics software technology, to print full-color anatomical models for diagnostic use and surgical planning. Materialise has received FDA clearance for software intended for 3D printing anatomical models for diagnostic and surgical planning uses, and introduced a program for…

Found in Robotics News & Content, with a score of 31.61

…printing system, the CBAM-2, and a new partnership with BASF on PA6-carbon fiber composites extend Impossible Objects’ composite based additive manufacturing process (CBAM) to a range of industrial applications. “It’s been exciting to see how our customers are putting our approach to work to create high-performance parts for everything from aircraft and cars to lightweight athletic gear,” says Impossible Objects founder and chairman Bob Swartz. “We’re continuing to bring machines, materials and expertise to the market to transform the entire manufacturing process, from prototyping through to high-volume production.” CBAM-2 Speeds Production of 3D Parts at Scale The new CBAM-2 3D…

Found in Robotics News & Content, with a score of 30.35

…solution for production 3D manufacturing. The printing system counts BASF, Materialise and Siemens as strategic partners, creating what HP calls “a new global community of proven large-scale 3D printed parts providers.” The printer is the latest refinement of HP’s work in Multi Jet Fusion (MJF) printing technology, which prints on a line-by-line basis. HP says the method is inspired by its long history of 2D wide format printing, but relies on a variety of innovations for 3D. HP says MJF allows for faster cooling and increased automation of post-processing compared to selective laser sintering (SLS). MJF allows almost 90% of…