Editors’ Picks

Found in Robotics News & Content, with a score of 6.69

…management. The Beijing-based company has deployed over 30,000 mobile robots for more than 700 global customers in the retail, apparel, third-party logistics (3PL), pharmaceutical, and automotive industries. Geek+ claimed that it offers “the industry's most extensive order-fulfillment product portfolio,” including its flagship shelf-to-person system, a tote-to-person-height storage system, a hybrid pallet storage and picking system, and a robotic sortation system. Geek+ said it AMRs help major brands like Nike, Wal-Mart, Toyota, and Siemens optimize their logistics using reliable products paired with after-sales services. Editor's note: Geek+ will be participating in the keynote session of the 2023 Robotics Applications Conference, presented…

Found in Robotics News & Content, with a score of 7.20

…business-to-consumer] operations, such as within 3PL [third-party logistics] and apparel industries.” ChainPick can save space, time The HaiPick A42T-E2. Source: Hai Robotics The telescopic Grapple Hook ACR can be integrated within HaiPick System 3, said Hai Robotics. The HaiPick A42T-E2 features a grappling hook that can pick a tote every 2.7 seconds. The ChainPick technology is key to enabling up to five-deep tote storage capacity, shortening pick-and-place times and streamlining the goods-to-person workflow, asserted the company. “Horizontal space in between totes can be slashed by 60%, ensuring no space gap at the back and hence optimizing existing warehouse storage space,”…

Found in Robotics News & Content, with a score of 12.84

…global expansion.” Founded in 1949, Adidas provides athletic footwear, apparel, and accessories. The Herzogenaurach, Germany-based company has 59,000 employees worldwide, and its 2022 revenue surpassed €22.5 billion ($23.6 billion U.S.). Adidas site can process 1M pieces per day Adidas said its 139,000-sq.-m (1.4 million-sq.-ft.) automated facility can process more than 1 million pieces per day and can hold 10 million pieces of apparel and footwear. Geek+ said its robotic systems addressed various challenges in Adidas' logistics and warehousing operations. This included customizations for detecting item locations, “significantly enhancing” operational safety, and aligning human-machine collaboration with Adidas' needs. In addition, Geek+…

Found in Robotics News & Content, with a score of 6.17

…chilled groceries, packaged goods, cosmetics, electronics, medical devices, polybagged apparel, and more. Rohlik goes live with Munich deployment In June, Brightpick announced the successful completion of a nine-month pilot of its robotic solution in the Prague fulfillment center of Rohlik Group. The company has more than 1.5 million e-grocery customers and 12 million orders per year. Since then, Rohlik has deployed Brightpick's robots in its Munich fulfillment center and plans to continue rolling out AMRs in Frankfurt, Vienna, Prague, and facilities into 2024. Rohlik's system includes Brightpick Autopicker and Dispatcher robots, enabling it to fully automate picking, consolidation, and dispatch…

Found in Robotics News & Content, with a score of 5.56

…design, deployment, and support expertise. The wholesale distributor of apparel and accessories said it hopes to meet evolving demand and optimize fulfillment. Körber and Geek+ seek to solve supply chain complexity “The supply chain has undergone tremendous changes in recent years, with an ever-increasing demand for efficiency and productivity while continually requiring more sustainable practices,” said Lit Fung, vice president and managing director of overseas business at Geek+. “We need innovative solutions to answer new challenges to be cost-efficient and competitive while also sustainable,” he said. “Driven by huge developments in AI and machine learning, robots can help by addressing…

Found in Robotics News & Content, with a score of 5.57

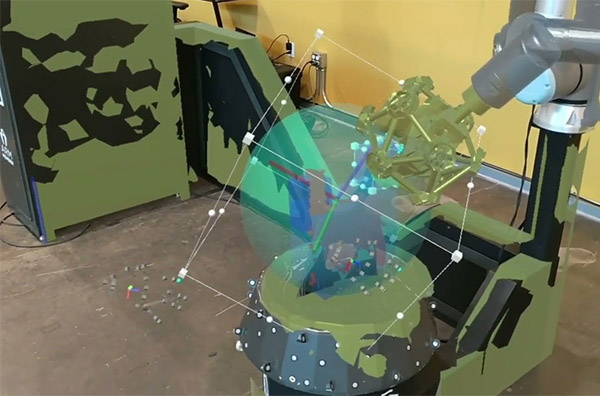

…Manipulating Fabric with Robots for Pick-and-Place Operations Project team: Apparel Robotics Corp. (principal investigator), MassRobotics Topic areas addressed: Automated robotic task planning and AI in robotics for manufacturing Description: Clothing manufacturing is a very labor-intensive process, with 80% of the total labor cost attributed to material handling, and most labor manufacturing is completed offshore. For the garment manufacturing industry to progress meaningfully towards automation, several effective fabric-handling technologies must arise. This project will develop new flexible robotic material handling capabilities required to unload a cutting table or a conveyor that has a number of cut nested fabric pieces of varying…

Found in Robotics News & Content, with a score of 7.07

…'23, special,” said Demaitre. “This will get a leading apparel brand, an integrator and software provider, and a mobile robot supplier together to share their requirements, challenges, and solutions.” End-user speakers in other sessions will represent diverse organizations including CCU, the Mayo Clinic, and nioform, plus major robotics suppliers such as Dexterity, Cyngn, inVia Robotics, and Vanderlande. Innovative software and component providers like Brightpick, inOrbit, and Microsoft are also slated to participate. The panels will examine a range of topics and use cases: Order fulfillment Goods-to-person systems and robot operations Piece picking Collaborative robots plus vision provide precision for more…

Found in Robotics News & Content, with a score of 6.09

…and unloading effortless for third-party logistics (3PL) providers, retailers, apparel manufacturers, and other material handlers,” claimed Dexterity. The company said its software release includes the following new features to expand warehouse operators' ability to automate their pallet operations: Print and apply integration—PDP 3.0 enables 3PLs to automate their case-in, case-out labeling processes. Dexterity automates Amazon FNSKU case-labeling process and other case relabeling value-added services. Pallet stacking—By enabling picking from up to five pallets stacked on one another, PDP 3.0 unlocks the utilization of work cells by minimizing the time for pallet swapping. Rolling cart loading adapter —Moving beyond pallets, PDP…

Found in Robotics News & Content, with a score of 3.51

…This is happening across a range of industries, including apparel, general merchandise, health and beauty, and pharmaceutical distributors. “Given the current economic climate, the push to further automate manual put walls is happening more prominently within projects that improve the efficiency and throughput of brownfield sites,” explained Fry. “Rather than building net-new facilities from the ground up, companies are looking to retrofit their current manual order sortation or put wall footprint with new robotic solutions to gain efficiency and cut costs.” With automated put walls, a robot arm picks up a single item from multi-SKU totes and then scans and…

Found in Robotics News & Content, with a score of 7.18

…has recently been highlighted as the 2024 problem.” “We will collaborate with PAL, which owns many popular brands of apparel and convenience goods, and acca international, which manages PAL’s warehousing and shipping operations, to create an innovative logistics system that will help increase the corporate value of both companies,” Tatewaki added.

Found in Robotics News & Content, with a score of 12.10

…that uses a smart strong pinch grip to prevent apparel from swaying to safely produce high pick and place rates How does it work? Pairing the Zivid 2+ 3D camera with Fizyr’s deep learning computer vision software provides unparalleled robustness for handling transparent objects, the companies claimed. Fizyr identifies each item with segmentation, shape detection and material detection, and its algorithms prioritize the actions to be taken with cascading considerations that identify which items are on top of others, the location and makeup of each item’s surfaces, whether the robot’s gripper will have adequate room to move, where it must…

Found in Robotics News & Content, with a score of 6.88

…operations at Ariat, described how labor scarcity drove the apparel retailer toward robotics. However, the transition from manual processes to software and data-driven automation requires effort, patience, and teamwork, observed Drew Bailey, vice president of design engineering at 3PL GEODIS. Companies considering automation should make their requirements clear to robotics suppliers and integrators, he said. Girton and Bailey cited challenges such as changing how they measure a floor's grade before implementing Skypod. Both noted that they were ultimately pleased with the results of their deployments, including significant increases in throughput. Integrators can help assess a customer's processes and collaborate to…