Editors’ Picks

Found in Robotics News & Content, with a score of 14.71

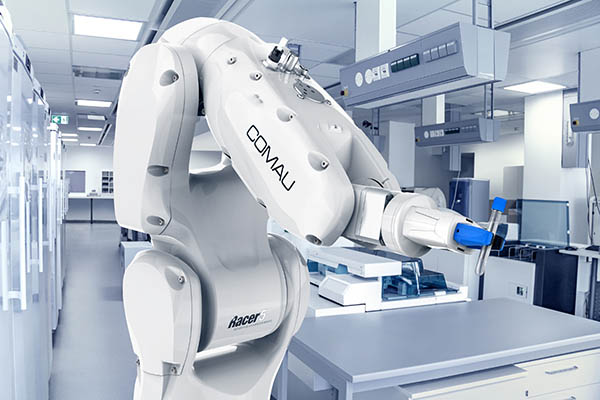

…a rigid construction to ensure higher precision and repeatability. It has been tested and certified for cleanroom compliance by Fraunhofer and is available in two different 5 kg (11 lb.) payload configurations, with a reach of 630 mm (24 in.) and 809 mm (31.85 in.).

Found in Robotics News & Content, with a score of 17.17

…A1, GO1, and ANYmal quadrupeds, as well as the Fraunhofer Institute's O3dyn (formerly “Obelix”) indoor/outdoor pallet-moving system. “Fraunhofer's AMR [autonomous mobile robot] is omnidirectional, can move fast, and can pick up heavy loads,” said Andrews. “It has plans to open-source the platform.” “Our panel on digital twins at Automate last week was well-received,” he recalled. “The panelists from companies like Kroger and our newly announced partnership with READY Robotics demonstrate that the technology is becoming really important to diverse users.” “Our discussions with them and people at our booth showed that it's not just the technology providers—end users are starting…

Found in Robotics News & Content, with a score of 22.85

…reasons why organizations are seeking automated solutions,” Mühlens said. Fraunhofer Institute designs dual-arm cucumber harvester Harvesting cucumbers is a physically demanding task. Some companies have workers lie prone on a support surface behind a vehicle, picking the vegetables off the vines by hand. In more rudimentary businesses, workers walk down rows carrying a harvesting bucket, bending down to look for the ripe cucumbers. Carrying boxes that weigh up to 12.2 kg (27 lb.), the workers must walk, bend, stoop, and reach. Finding workers to perform these tasks has become increasingly difficult. In response to this challenge, the Fraunhofer Institute for…

Found in Robotics News & Content, with a score of 13.91

…use Wandelbots' software at customers like BMW, Bayer, VW, Fraunhofer, Schaeffler, Rotop, and Vitesco. The company has also partnered with operational technology (OT) systems integrators in Europe such as Gibas, Alumotion, Heidenbluth, and Sojka. Wandelbots plans to use its latest financing to open its Robotics Software Platform to automation providers and the third-party developer community. The opening will enable developers to build their own robotics applications on top of a manufacturer-agnostic control plane, the company said. Insight Parters leads funding, joins board Insight Partners led Wandelbots' Series C round. Existing investors 83North, Microsoft, Next47, Paua, Atlantic Labs, Haniel, and EQT…

Found in Robotics News & Content, with a score of 10.41

…this early stage, the logistics team worked with the Fraunhofer Institute for Material Flow and Logistics IML in Dortmund to document the requirements for a new facility. After picking, the contents of each tote is photographed. Source: HARTING Technology Group Ideas competition In 2013, HARTING sent a 300-page requirements document to 10 companies it believed might be interested in creating the warehouse. One of the criteria was that there be one general contractor for the building and one integrator for the systems in the facility, including the WMS. While awaiting proposals, Meyer and his team visited more than 100 warehouses…

Found in Robotics News & Content, with a score of 39.68

…Industries news, the company launched a new partnership with Fraunhofer Project Center at the University of Twente and the Fraunhofer Institute for Production Technology IPT in Aachen, Germany. Ampower, an additive manufacturing consultancy, concluded in their independent benchmark study “Productivity Evaluation for Metal Additive Manufacturing Systems” that Additive Industries’ MetalFAB1 systems combine the lowest system investment with the lowest total cost per part and highest annual capacity. They tested four typical parts from various industries like medical hip implants, impellors from oil and gas industries, and parts from the automotive and aerospace industry. In all cases the MetalFAB1 won over…

Found in Robotics News & Content, with a score of 35.11

…positive interim result of the Bionic Aircraft project: The Fraunhofer Institute for Additive Production Technologies IAPT, has developed optimized support structures. Support structures provide the needed support to additive manufactured components at certain areas, for example at overhangs, and must be removed after the 3D print. “Thanks to an optimized geometry, the new support structures do not need as much powder. We were inspired by nature, which is known for its material efficiency. The hierarchically branched structures with gradients that were created as a result reduce powder consumption by 70 to 90 percent as compared to conventional support structures. This…

Found in Robotics News & Content, with a score of 14.78

…impact. It also features a review of ongoing trends plus insights from industry thought-leaders such as the World Bank, Fraunhofer Institute, HP and 500 Startups on the future of the logistics industry. Transformative pilot projects from DHL Trend Research are also highlighted in the report such as DHL’s testing of collaborative robots in warehouse operations.