Editors’ Picks

Found in Robotics News & Content, with a score of 14.10

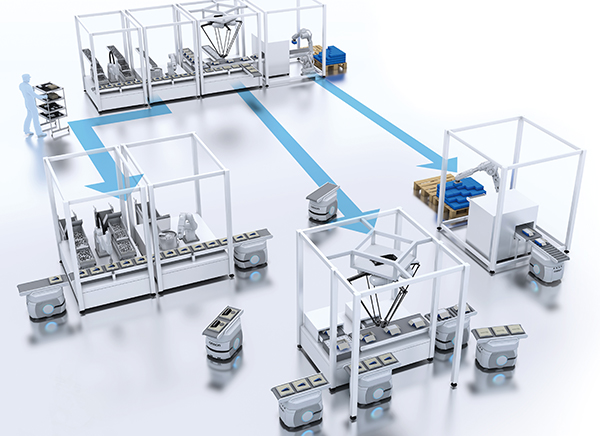

…as those found in aerospace applications. A U.K. automotive fabric manufacturer uses such vision systems from Shelton Vision for real-time fabric inspection. Manual inspection is impossible because of the speed of fabric throughput and the different lighting required for identifying specific defects. Automated vision systems use all lighting conditions to identify every possible defect to a range of subtlety impossible by manual means. Defects are graded, classified, and mapped at speeds 10 times that of human ability, increasing productivity and decreasing non-conforming product shipments. 3. Flexible routing copes with capacity challenges Routing flexibility is the ability for multiple robots to…

Found in Robotics News & Content, with a score of 14.06

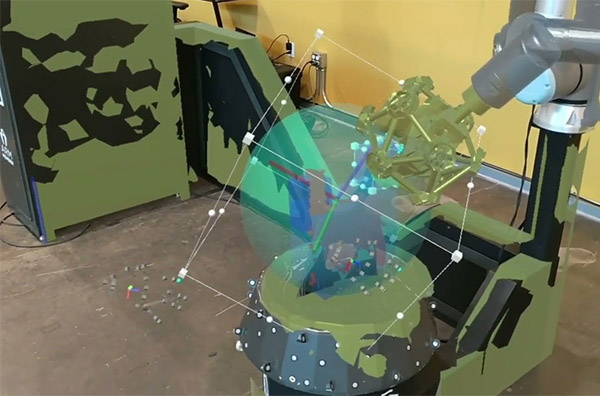

…and accuracy for almost any robotic manufacturing application. Manipulating Fabric with Robots for Pick-and-Place Operations Project team: Apparel Robotics Corp. (principal investigator), MassRobotics Topic areas addressed: Automated robotic task planning and AI in robotics for manufacturing Description: Clothing manufacturing is a very labor-intensive process, with 80% of the total labor cost attributed to material handling, and most labor manufacturing is completed offshore. For the garment manufacturing industry to progress meaningfully towards automation, several effective fabric-handling technologies must arise. This project will develop new flexible robotic material handling capabilities required to unload a cutting table or a conveyor that has a…

Found in Robotics News & Content, with a score of 11.44

…simultaneously improving visibility. “As demands expand the scope and scale of potential services, 3PLs must weave deeper into the fabric of a shipper’s supply chain,” she concludes.

Found in Robotics News & Content, with a score of 10.90

…to whatever work needs to be done. From abrasion-resistant fabrics to engineering-grade polymers and aircraft-grade aluminum, the suit will hold up to the most rigorous situations and years of hard work, the company said. Ease of use: With the Apex 2, it is easier to size and train new users, and donning and doffing is faster and more intuitive, HeroWear asserted. The redesigned, patent-pending switch is intended to make it easy for users to activate assistance when they need support and deactivate it when they don’t. HeroWear launched Apex 2 this week via a virtual stream (see below). The company…

Found in Robotics News & Content, with a score of 10.08

…Soft robots, which are made with flexible materials like fabric and rubber, are still relatively new technology compared to rigid robots which are already widely in use in manufacturing. Rigid robots have many limitations including their high cost and high safety concerns — two problems soft robots can potentially solve, said study co-author Ming Luo, an assistant professor in WSU’s School of Mechanical and Materials Engineering. “We make soft robots that are naturally safe, so we don’t have to focus a lot on expensive hardware and sensors to guarantee safety like what has to be done with rigid robots,” said…

Found in Robotics News & Content, with a score of 9.92

…but also in stitching a continuous thread through the fabric of community engagement. From student contests to educational partnerships, the organization said its first quarter was teeming with activity, enthusiasm, and the indelible spirit of innovation. Reflecting the HRC's dedication to advancing robotics and technical literacy, the organization said this quarter's initiatives bolster STEM education and provide exciting avenues for community participation. The HRC is supported by a $25 million federal award to the University of Nebraska–Lincoln announced in 2022, which is part of the U.S. Department of Commerce’s $1 billion Build Back Better Regional Challenge program. Northeast and Metro…

Found in Robotics News & Content, with a score of 9.22

…had led to the development of barriers comprised of fabric, plastics and other new materials—and a growing awareness that safety barriers are no longer a one-size-fits-all proposition,” says Troy Bergum, product manager at Rite-Hite. “Safety and facility managers need to become more sophisticated in their evaluations of barrier needs, analyzing location-specific traffic patterns and other issues, rather than just defaulting to steel that is heavy enough to withstand 10,000 pounds at 4 mph.” Dock seals: In addition, another means of protection—dock seals—are also being replaced with new alternatives, as they do not currently have the longevity they once did, primarily…

Found in Robotics News & Content, with a score of 9.00

…us to use certain materials, such as plastics or fabrics, to make our system more flexible, lightweight, and cost-effective. It's only a few thousand dollars, compared with tens or hundreds of thousands.” “These materials also enable us to rapidly prototype and innovate, unlike traditional prototyping and 3D printing, which are time-consuming and expensive,” he added. “This enables us to tailor the system to human anatomy and more easily scale up.” “The knee actuator transmits torque for movement,” he explained. “One area of customization is optimizing fit for comfort. We can take a user's measurements for the thigh and lap components…

Found in Robotics News & Content, with a score of 8.21

…will happen to Chowbotics' staff or intellectual property. Get Fabric Inc.—New York-based Fabric raised $200 million in Series C funding in October 2021 and opened a micro-fulfillment center in Dallas in April. This week, the company laid off 40% of its 300-person staff and named a new CEO as part of a reorganization to being more of a platform provider than a service provider. “Most of our customers told us they prefer to operate our system on their premises and with their own teams,” CEO Avi Jacoby told TechCrunch. Nuro Inc.—The Mountain View, Calif.-based company, which we named a “delivery…

Found in Robotics News & Content, with a score of 7.75

…with inhibited mobility, said the partners. The lightweight, breathable fabric feels like an athletic legging and is available in multiple colors and sizes, said Cionic. Paired with an intuitive app, the sleeve enables users to be in control of their own mobility journeys, it claimed. “It was imperative to us that the product not only has a significant improvement for users physically, but also to remove some of the emotional burdens that come with having a mobility difference,” said Behar, founder and CEO of fuseproject. “This meant building a product in tandem with potential users so we understood their needs…

Found in Robotics News & Content, with a score of 7.50

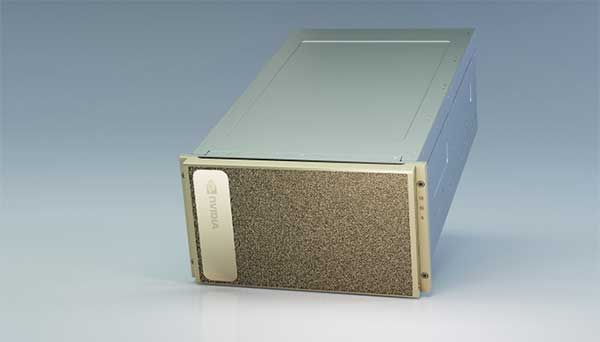

…12.4TB per second in bandwidth. Six NVIDIA NVSwitch interconnect fabrics with third-generation NVIDIA NVLink technology for 4.8TB per second of bidirectional bandwidth. Nine Mellanox ConnectX-6 HDR 200Gb per second network interfaces, offering a total of 3.6Tb per second of bidirectional bandwidth. Mellanox In-Network Computing and network acceleration engines such as RDMA, GPUDirect and Scalable Hierarchical Aggregation and Reduction Protocol (SHARP) to enable the highest performance and scalability. NVIDIA DGX software stack, which includes optimized software for AI and data science workloads, delivering maximized performance and enabling enterprises to achieve a faster return on their investment in AI infrastructure. A single…

Found in Robotics News & Content, with a score of 7.48

…to automated pick, place, and form for processing CMC fabric prepregs using 3D vision-based sensors to reduce the cost and variability for high-rate production of CMC structures. Benefits of this approach include having a cost-competitive alternative to titanium, higher processing efficiency, and applications for other materials and processes. Rapid Welding of Thermoplastic Composite Structure Source: Raythenon Technologies Principal Investigator: Raytheon Technologies Research Center Project Team: Carnegie Mellon University, Wason Technology LLC, and Collins Aerospace Project Description: Lightweight carbon fiber reinforced thermoplastic composites (CF-TPCs) are internationally recognized as a material capable of meeting the future aerospace market high-rate demands and providing…