Editors’ Picks

Found in Robotics News & Content, with a score of 33.40

…it is also quickly raising funding for its robotic machine operator. In its third fundraising in less than a year, the San Francisco startup today announced a $36.7 million Series B round. The company said its Rapid Machine Operator enables manufacturers to deploy a pretrained collaborative robot in hours without any specialized skills, systems integration, or programming. Since emerging from stealth in late 2020, Rapid Robotics said it has addressed the needs of American manufacturers as they face a labor shortage aggravated by the COVID-19 pandemic. According to a recent study from Deloitte and The Manufacturing Institute, by the end…

Found in Robotics News & Content, with a score of 9.05

…tasks such as visual inspection for quality control than machine tending or pick-and-place tasks, which don't always make sense for ROI [return on investment],” he said. On the software side, Version 2 of MiR's fleet management software is available, and the company and some of its customers are watching various interoperability efforts. “Our system is fairly open,” said Charles. “With REST APIs [application programming interfaces], you can get fleet and position information from the robots, whch is what you need for systems from different vendors to work together. A lot of software providers are looking at providing another layer.” Top…

Found in Robotics News & Content, with a score of 12.26

…working on making tasks such as welding, assembly, and machine tending easier for robots to do. Wendy Tan-White, Intrinsic CEO “Our team has been exploring how to give industrial robots the ability to sense, learn, and automatically make adjustments as they’re completing tasks, so they work in a wider range of settings and applications,” said Tan-White. “Working in collaboration with teams across Alphabet, and with our partners in real-world manufacturing settings, we’ve been testing software that uses techniques like automated perception, deep learning, reinforcement learning, motion planning, simulation, and force control.” “In one instance, we trained a robot in two…

Found in Robotics News & Content, with a score of 25.12

Automating machine loading traditionally means integrating conveyors, bowl feeders, custom trays, shaker tables, or various other components and processes. These approaches can lead to a range of obstacles, including complex programming and setup, poorly used manpower, inefficient machine utilization, and decreased output, according to Universal Robots A/S. Universal Robots said its ActiNav product combines intelligent vision and sensor software with autonomous motion control of collaborative robot arms in one Application Kit. The Odense, Denmark-based company claimed that ActiNav can solve the random bin-picking challenge in machine tending applications. To give manufacturers an opportunity to experience ActiNav firsthand, Universal Robots plans…

Found in Robotics News & Content, with a score of 15.71

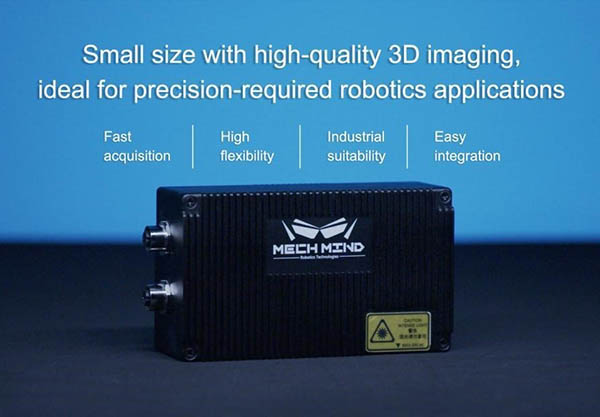

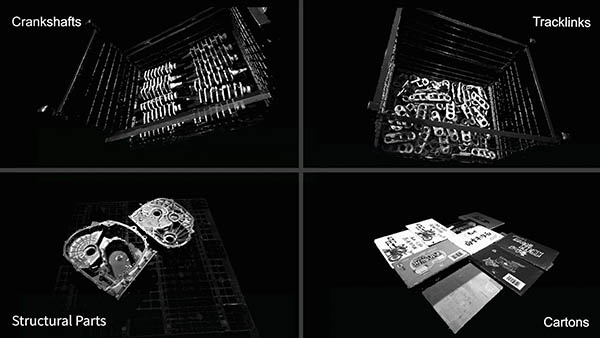

…solutions for palletizing and depalletizing, bin picking, order sorting, machine tending, and assembly/gluing/locating in logistics and manufacturing. It raised Series C financing in May, bringing its total funding to more than $100 million (U.S.). Mech-Eye Nano promises precision The palm-sized Mech-Eye Nano uses fast structured light to generate complete, detailed, and accurate point clouds with native and perfectly aligned color, said Mech-Mind. It can perceive a wide variety of objects, including tiny, shiny, reflective, and colored ones, with depth accuracy optimized to 0.05 mm at 0.3-0.4 m, according to the company. In pick-and-place robotics, Mech-Eye Nano enables demanding applications, including…

Found in Robotics News & Content, with a score of 17.02

…24/7. MIRAI designed to hasten flexible robot use Certain machine tending, assembly, or test applications have been difficult to automate because of variances in position, shape, surface properties, or lighting conditions. Previously, human labor was required for production tasks involving different placement of workpieces, gripping objects with unstable shapes, or picking reflective or transparent materials. MIRAI uses artificial intelligence and machine vision to enable robots to react to variances in tasks in real time by learning from humans, said Micropsi. With the company's distribution and integration network, the control system is designed to enable users to deploy automation without in-house…

Found in Robotics News & Content, with a score of 20.05

…control) equipment, learning to program, set up, and operate machines that produce parts for industries including aerospace, medical, defense, and automotive. The expanded coursework provides technical skills training in robotic programming and various collaborative robotic tasks such as machine tending. The 40,000 square-foot workforce training facility offers an accelerated five-month program for adults and a 10-month program for young adults. The Robotics Center has the support of many companies that operate in the robotics and automation space, with many of them providing robots, software, services, and accessories. Sponsors and supporters of the new center include: Teradyne, owner of Universal Robots…

Found in Robotics News & Content, with a score of 28.91

…for applications such as packaging, quality control, materials handling, machine tending, packaging, assembly, and surface finishing. MAP to make applying OnRobot tooling easier Vention said MAP provides users with the engineering software and modular hardware they need to design, automate, order, and deploy factory equipment in a single digital environment. With thousands of modular parts, smart design tools, and real-time pricing, factory equipment can be designed in minutes from anywhere, on any web browser, it said. The addition of OnRobot’s plug-and-play tools for collaborative and light industrial robots will allow manufacturers to focus on scaling production with greater flexibility and…

Found in Robotics News & Content, with a score of 17.87

…recently completed a Series C funding round. The Beijing-based machine vision company said the latest investment brings its total funding to more than $100 million (U.S.), making it one of the world's most funded artificial intelligence and industrial automation startups. “Our products are designed to fundamentally reframe the manufacturing pain points by utilizing the practice of AI and human-robotics interaction,” stated Tianlan Shao, founder and CEO of Mech-Mind Robotics. “Our products and service already create visible business returns for nearly 1,000 clients worldwide.” Manufacturing remains the largest adopter of industrial automation globally, according to the International Federation of Robotics, as…

Found in Robotics News & Content, with a score of 24.19

…customer feedback and expands potential applications such as palletizing, machine tending, and packaging. The robot’s price remains unchanged, said Universal Robots. “Universal Robots is committed to continuous improvement based on meaningful conversations with customers and our ability to address critical market opportunities,” stated Kim Povlsen, president of Universal Robots. “Our customers have already deployed UR cobots on a wide variety of palletizing applications.” “Over time, they have identified opportunities to utilize our UR10e cobot in handling tasks with heavier items,” he said. “In response to this demand, we have enhanced the UR10e to support greater payloads, providing customers with exciting…

Found in Robotics News & Content, with a score of 14.56

…Columbus, Ohio-based company said that its offering will enable machine builders and software developers to create applications that scale across robot and automation brands. “For robotics to reach the scale we need as a society, we must make it easier for end users, and we must make it easier for developers,” stated Benjamin Gibbs, co-founder and CEO of READY Robotics. “As we’ve seen before with Windows and Android, software platforms can enable massive growth within an industry.” Founded in 2016, READY Robotics claimed that Forge/OS is the “first enterprise-grade operating system” for controlling hundreds of models of industrial and collaborative…

Found in Robotics News & Content, with a score of 13.55

…and motion planning software for applications like bin picking, machine tending, packaging, and assembly.” The ARM Institute said it plans to host more fellows in the future. The next call for ARM Institute Fellows is slated for fall 2021. The institute is also involved in three other Defense Manufacturing Communities, which are funded by the DoD’s Office of Local Defense Community Cooperation (OLDCC). About the program sponsors Founded in 2017, the ARM Institute is intended to help U.S. manufacturers be competitive and resilient through the use of robots and workforce development. The Pittsburgh-based institute is a public-private partnership sponsored by…