Editors’ Picks

Found in Robotics News & Content, with a score of 9.07

…chain, and they also make for a safer, more ergonomic work environment. To continue meeting growing demand for its bakery products and stock its stores throughout the Midwest, Kwik Trip made plans in 2017 to open a new 200,000-square-foot baking facility in La Crosse, Wis., which would be dedicated to producing bread and buns across three simultaneous lines. The facility would need to come online and get up to speed in concert with the repurposing of the previous one—and ultimately produce and distribute four times the volume of output. To meet these requirements, the logical choice was to automate as…

Found in Robotics News & Content, with a score of 3.09

…were deployed and implemented with the primary focus of maximizing space utilization, throughput and productivity. Other than a few ergonomic considerations, little was done to design facilities in a way that also mitigated labor and productivity risks due to previously unknown threats such as disease spread. Automating DC operations and employing AI technologies that include a closer convergence of WCS, WES and WMS solutions is on the horizon. Designing touchless fulfillment centers that reduce the dependence on traditional labor sources through innovative technologies will better position supply chains in their quest to provide an uninterrupted flow of goods and resiliency…

Found in Robotics News & Content, with a score of 9.49

…fulfillment process that adapts to changing customer needs, reducing ergonomic issues linked to maneuvering heavy manual carts, energizing warehouse associates with easy-to-use technology, and ramping fulfillment capacity to meet growing consumer demand. Office Depot replaced its manual cart and pick-to-voice technology at a DC in Orlando, Fla., with a process that uses collaborative mobile robots (6 River Systems) to support efficient picking of e-commerce and store replenishment orders. The fleet of 18 autonomous mobile robots (AMRs) work in close collaboration with warehouse associates to get orders picked quickly and accurately with minimal walking for the workers. The AMRs, or “Chucks”…

Found in Robotics News & Content, with a score of 7.48

…will augment warehouse productivity, order pick accuracy, and workplace ergonomics and safety. And they added that PLG and Whiplash, PLG’s end-to-end e-commerce platform are well-positioned to meet the ongoing surge in e-commerce demand, which has been a major theme of 2020 because of the ongoing COVID-19 pandemic, and seen retailers and merchants looking for ways to meet consumer demand, which is impacted by a retail environment that is often difficult to navigate. “PLG has been a Locus customer since deploying our solution in its New Jersey warehouse location,” said Karen Leavitt, CMO Locus Robotics, in an interview. “The success they…

Found in Robotics News & Content, with a score of 3.14

…the forks are. “Camera systems increase safety and improve ergonomics,” says Wels. “They give operators a better view, which saves time and increases productivity.” A new feature for Yale is a pair of digital cameras integrated with a vehicle’s telematics impact sensor. When an impact occurs, a mobile app feature presents users with a video clip that shows 3 minutes prior to the impact and 3 minutes after. “You get a visual record of what happened, and enhanced accountability,” says Paramore. The integrated camera setup from Yale can also be used to capture video footage on demand to visually document…

Found in Robotics News & Content, with a score of 3.51

…only with growth in mind, but also to be ergonomic and sustainable. The solution features a representation of most of the tools from the materials handling tool box, including: A cross-belt sortation system capable of handling 6,000 cases per hour. A seven-crane pallet handling automated storage and retrieval system (AS/RS) with 48,000 pallet locations. A 22-crane case handling mini-load AS/RS with space to store approximately 500,000 cartons. An AutoStore goods-to-person picking system, currently being expanded to 12 decanting stations, with 224 robots and the capacity to store 116,300 bins serving 24 pick stations. A three-level garment-on-hanger storage and pick mezzanine.…

Found in Robotics News & Content, with a score of 3.38

…is an underwater scooter, which replicates a dolphin’s body ergonomics for faster movement, and it is also emissions-free with low noise operation—an attempt to minimize impact on the marine ecosystem. Another point of disruption: 75% of the Amazea—specifically, the scooter’s body and front parts—are produced with BigRep large-scale 3D printing technologies in contrast to using traditional casting or injection molding methods. Underwater scooter produced using BigRep's technologies. Image courtesy of JAMADE/BigRep. Large-scale additive manufacturing (AM), and the BigRep One printer in particular, fit the bill because they deliver cost efficiencies along with better accuracy and quality compared to the high…

Found in Robotics News & Content, with a score of 9.50

…technology enables Signicast and DDM customers to create more ergonomic components with less material cost and shorter lead times. “DDM is extremely proud to join hands with Signicast to modernize investment casting while offering speed, complexity and value to customers. This partnership greatly accelerates the introduction of DDM's ceramic 3D printing based Digital Foundry offering to the market,” says Dr. Suman Das, founder and CEO of DDM. “DDM's 3D printing technology will bolster our core offering and amplify our footprint in additive manufacturing,” says Marc Riquelme, president of Signicast. The partnership between Signicast and DDM highlights advancements in precision casting…

Found in Robotics News & Content, with a score of 7.85

ProGlove, a leader in ergonomic wearable technology for industry, was selected among hundreds of candidates as one of the World Economic Forum’s “Technology Pioneers.” The World Economic Forum’s Technology Pioneers are early to growth-stage companies from around the world that are involved in the design, development and deployment of new technologies and innovations, and are poised to have a significant impact on business and society. Technology Pioneers community is an integral part of the larger Global Innovators community of start-ups at the World Economic Forum. Following its selection as Technology Pioneer, ProGlove CEO Andreas Koenig will be invited to participate…

Found in Robotics News & Content, with a score of 7.39

…to support its employees and improve customer operations. “Automation and collaborative robotics help us make operational processes more flexible, ergonomic and more attractive to our employees by replacing monotonous, repetitive and particularly strenuous activities,” he said. “The aim is not to replace employees over time, but to assign the more attractive and interesting tasks to our human workforce.”

Found in Robotics News & Content, with a score of 9.32

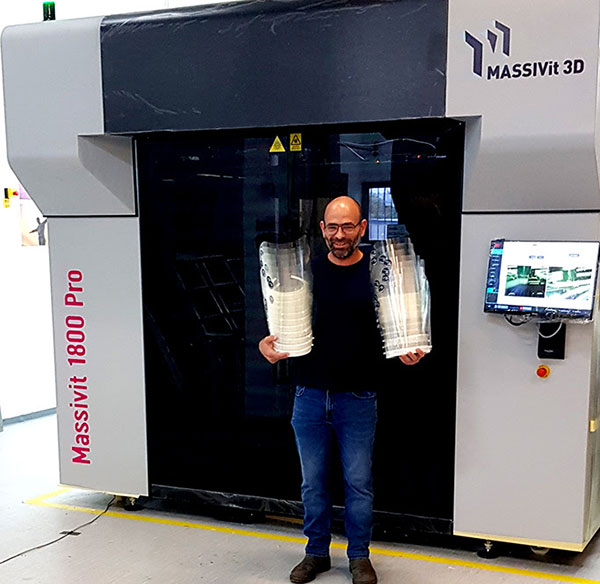

…its network of over 100 customers and distributors worldwide, ergonomic PPE Face Shields have been conceived and produced to address the demand by medical teams caring for the victims of the pandemic. Massivit 3D’s high-speed additive manufacturing technology allows for the supply of hundreds of face shields off each machine every day. In addition to devoting all of its manufacturing resources to producing and donating thousands of face shields to medical teams at local hospitals with a less than one-day turnaround, the company has also made available to all, the optimized 3D print files of the newly developed face shields.…

Found in Robotics News & Content, with a score of 11.10

…gets them where they need to be, when they need to be there. The solution is based on an ergonomic headset, wearable mobile device and advanced software that utilizes “text-to-speech” and “speech-to-text” technology (currently available in 41 languages). By converting warehouse management system information to speech, Honeywell Voice provides audible instructions to warehouse operators — directing them to the next location and guiding them through the required tasks or steps to complete processes, such as picking, inventory replenishment, maintenance and repairs.