Editors’ Picks

Found in Robotics News & Content, with a score of 12.15

…including assembly, inspection, material handling, packaging, palletizing, sanding, and welding. “Our collaborative robots are easy to use and flexible solutions for companies looking to enhance productivity and solve labor issues,” said Eric Potter, general manager of the General Industry and Automotive Segment at FANUC America. “We’ve seen substantial growth in the cobot space, particularly from companies who are new to robotic automation,” he said. “We’re excited to introduce the CRX-25iA cobot with a 30 kg [66.1 lb.] payload capacity, and the CR-35iB cobot with a 50 kg payload capacity. Now, customers can easily handle heavier products with these models.” FANUC…

Found in Robotics News & Content, with a score of 12.14

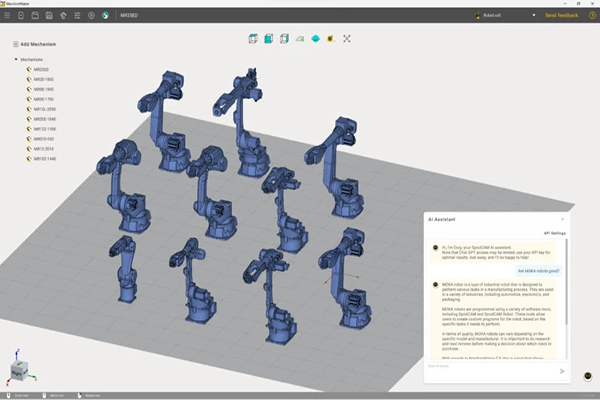

…than 10 series of industrial robot products, including hollow welding robots, handling robots, loading and unloading robots, special robots for die-casting and grinding, stamping robots and others. The SprutCAM X Robot Components Library now includes the following MOKA robot models: MR07S-930, MR08-1840, MR10L-2050, MR10Z-1440, MR12-2010, MR12Z-1550, MR20-1800, MR20E-1840, MR25ED, and MR30-1700. Other enhancements and improvements SprutCAM updated the list of operations for the 2.5D Milling configuration and added Chamfering and 2.5D Contouring operations to the Cutting configuration for robotic machining. Another change in the software update include a change in font size in the CLData Viewer (post processor debugging application)…

Found in Robotics News & Content, with a score of 12.03

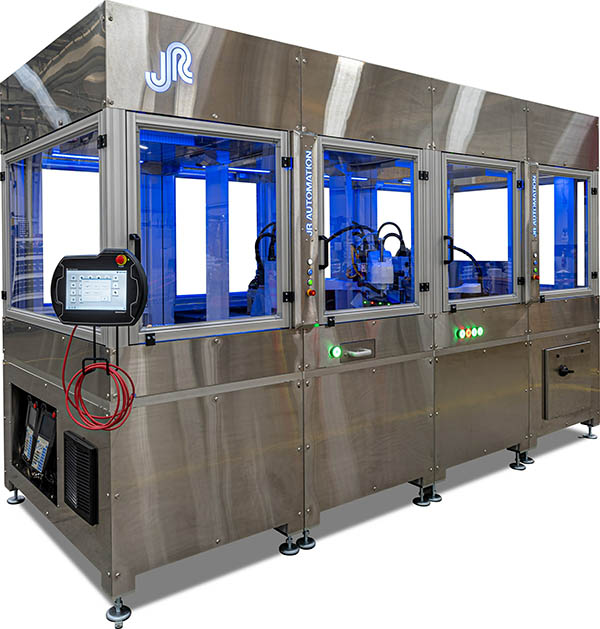

…goods, and electronics manufacturing markets. Assembly capabilities include: Ultrasonic welding Riveting Screwing Snap fit Gluing UV gluing Decorating, Heat Sealing, Joining dissimilar materials Material joining capabilities include: Heat/ultrasonic foil sealing Laser tacking Laser ablation Laser or ultrasonic cutting and die cutting FlexChassis’ configurability enables a range of use cases FlexChassis also includes full digital control and process monitoring. Additionally, linear motors give FlexChassis speed, accuracy, and operational flexibility with multiple configurations through a human machine interface recipe selection. From UL and CE to FDA and Gamp5, the FlexChassis design can be tailored to match specific production requirements. For clean manufacturing…

Found in Robotics News & Content, with a score of 11.98

…and dust resistant mainly for handling but also for welding. And, it’s a bunch of history. We're going back to the red color that has been always the iconic color of Comau robotics. One particular solution we are very proud of is our Mi.RA/OnePicker. We are talking about a system for picking that through a visual system can recognize objects of different dimensions and decide what actions to do. That is also part of our strategy. We are a company with a long heritage in the automotive business. But we are now moving in other sectors. And this is why…

Found in Robotics News & Content, with a score of 11.92

…company said the robot is suitable for palletizing and welding applications. Powered by the same 5A output source, CS625 features a maximum payload of 25 kg (55 lb.) and a radius of 1500 mm (59 in.), slightly sacrificing reach for greater robustness, accuracy, and strength, Elite Robots said. Like all other models in the CS series, the CS620 and CS625 robotic arms feature an IP68 degree of protection and ISO Class 5 clean rooms, making them suitable for both harsh environments and those requiring a high level of hygiene. Elite Robot highlights scanning technologies Elite Robots will also showcase the…

Found in Robotics News & Content, with a score of 11.90

…of collaborative arms, as of late, has been arc welding, said Joe Campbell, senior manager of strategic marketing and application development at Universal Robots. Arc welding involves connecting pieces of metal electrically and is often used by metal fabricators. “In our world, it’s three times bigger than it was a couple of years ago,” he told Robotics 24/7. “It’s actually a little over 6% of our total volume. That’s new, and it’s continuing to grow every month.” Universal Robots recently reported a record annual revenue of over $311 million, up 41% from 2020 and 23% from 2019. While Universal Robots…

Found in Robotics News & Content, with a score of 11.90

…such as this T702V. Source: ABB Robotics Cobots for welding, 3D printing, assembly The new GoFa cobot welding package features the Easy Teach Device and Wizard Easy Programming software to empower first-time robot users to create high-quality welds without the need for in-depth knowledge of robot programming. The new package is intended to make part changing easy and for both low-volume, high-mix and high-volume, low-mix operations. The GoFa works with power-source equipment from any of the major suppliers, said ABB. In addition, the company will provide a live demonstration of its CRB15000 GoFa cobot for plastic additive manufacturing. The “absolute…

Found in Robotics News & Content, with a score of 11.87

…a robotic welder, it considered several automated and traditional welding companies and ultimately decided on a unit from Hirebotics. The key factor in the decision was ease of use. “When we started looking into the technology, we saw just how easy these robots were to operate,” recalled Montes. “That was the real game changer for me. From my perspective, it would be a waste of time and money acquiring a robot, only to have it sit unused because it was too hard to operate.” To achieve ease of use, a number of design techniques come into play. “Hirebotics’ cobot runs…

Found in Robotics News & Content, with a score of 11.83

…tailored to human needs. From machine tending to palletizing, welding, and F&B services, the company said it offers a diverse array of ready-to-sell solutions catered to both domestic and global markets. That is why Doosan Robotics’ theme at Automate 2024 is “The Motion Platform Company.” At the show, Doosan Robotics unveiled its latest industrial cobot with new capabilities. The cobot comes with a 30 kg (65 pound) payload. Doosan Robotics booth will feature Dart-Suite, an advanced robot ecosystem designed to redefine the way customers utilize Doosan cobots. The scalable platform elevates cobot capabilities by providing unlimited programmable motions, while ensuring…

Found in Robotics News & Content, with a score of 11.78

…needed. “Although we’re very familiar and experienced with ultrasonic welding applications, integrating ultrasonic welders to the end of the robots was actually new to us,” said Hornsby. “Instead of moving a part manually or having a very customized fixture to move it around underneath our sonic welder, we chose the Epson T-Series All-in-One SCARA robots to automate the process for efficient speed, efficient costs, and efficient results.” Epson T-Series All-in-One SCARA robots are space-saving robots that install in minutes due to the controller being built into the base of the robot arm. They use the same intuitive software and powerful…

Found in Robotics News & Content, with a score of 11.36

…have been used for loading and unloading, bin picking, welding, palletizing, quality inspection, and more. Dobot seizes on market challenges The company said it made the Nova Series in response to labor shortages and rising costs in the service and retail industries. It said its robots can “replace workers to help reduce operating expense and decrease human contacts [sic] during pandemics.” “To better capture this newfound demand, Dobot has developed the Nova Series of collaborative robots designed specifically for retail customers to handle tasks such as making coffee, cocktail, ice cream, noodles, fried chicken, and even physical therapy,” it said.…

Found in Robotics News & Content, with a score of 11.36

…agreement includes functional packages covering various production tasks, from spot-welding, riveting, and dispensing to flow drilling and ultrasonic weld inspection. Each package is a ready-to-use, customer-proven combination of hardware, software, and services and will be implemented at Volvo Cars’ facilities in Torslanda, Sweden, and Daqing, China. Alongside the hardware and functional packages, ABB’s latest range of OmniCore robot controllers will help deliver energy savings of up to 20 percent at sites due to their highly efficient power electronics and use of regenerative braking within the robot. “The automotive industry’s historic transformation, driven by increasing consumer demand for electric vehicles and…