Editors’ Picks

Partnering with Anantak, ePicker (Booth C7294b), a robotics company, has developed an autonomous pallet mover and is introducing it during Modex. Using 3D cameras, lasers and vehicle telemetry, along with a proprietary self-driving software package, the pallet mover can accompany users’ existing workflows, rather than replacing them. Additionally, the pallet mover enables quick adoption—distinct from traditional mobile robotics that generally require considerable modifications to their infrastructure and processes to ensure they can run autonomously. This fast adoption is primarily because users remain at the front-end of the process, prior to the engagement of onboard autonomy. Transportation and drop-offs to facility…

Hit Promotional Products Inc. claims to be the largest promotional product manufacturer in the U.S., nationally recognized for its value and customer service. To maintain its positive reputation and continue offering a wide range of products, the Largo, Fla.-based company decided to embark on a multi-year initiative to reimagine its business processes from end to end. Hit continually introduces more than 500 new items per year and has been a member of the promotional products industry for more than 50 years. In particular, the company wanted to implement “lights-out” automation to package its products. Facing both rapid growth and marketplace…

Prime Robotics (Booth 8837) has unveiled a groundbreaking robotics platform for warehouses, known as the Auto Shelf. Unlike previous Autonomous Mobile Robotics (AMR) systems, the Auto Shelf can actually integrate into every shelf. As a result, all shelves can move and interact with workers directly and immediately. And, due to the Auto Shelf’s fully patented design, they will drive themselves to their own destinations when-ever they’re needed. In turn, every shelf is now a robot that has intelligence, leading to faster pick speeds and enhanced inventory accuracy, as employees no longer need to pick up or move shelves. Consequently, human…

During a Tuesday press conference at Modex, Fetch Robotics (Booth 9011) introduced and demoed its CartConnect500—an addition to the CartConnect lineup of autonomous mobile robots (AMRs), which is the industry’s first (and so far only) autonomous cart transport solution for numerous payloads. Featuring the company’s Freight500 robot base, along with an attached lift module, the CartConnect500 can pick up a FetchCart, a detachable, industrial-grade cart that was designed specifically for the new solution. Along with the FetchCart, the CartConnect500 can also transport virtually any type of cart that meets customers’ requirements, so that they can use carts that are already…

During a Wednesday press conference, Jim Tompkins, CEO of Tompkins International (Booth S4250), provided an overview of the company’s core competencies ecosystem, which includes Tompkins Robotics. Offering live product demonstrations, Tompkins explained the benefits of Tompkins Robotics, the world’s first portable, automated unit and parcel sortation system. Implemented within five to seven months (roughly 50% less than most sorter lead times), the sortation system—branded as t-Sort and t-Sort Plus—can be charged within five to eight minutes and run for three to four hours per charge. Ranging in payloads from 5 kg (t-Sort) to upwards of 30 kg and 55 kg…

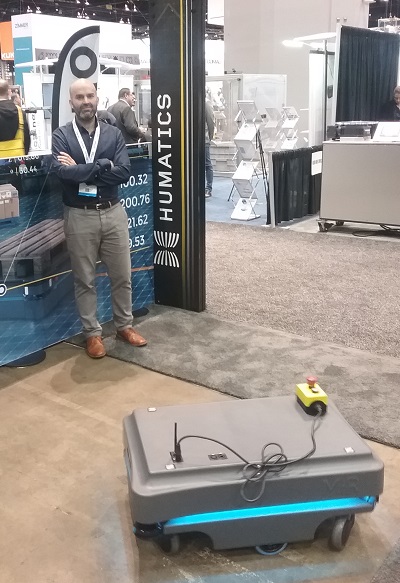

Earlier this week, Humatics Corporation (Booth N8370) revealed its partnership with Vecna Robotics, an autonomous logistics solutions leader. Through the partnership, Humatics will now be able to assimilate its KinetIQ 300 microlocation system into Vecna’s self-driving vehicle fleet. As a result of this integration, the vehicles can navigate outdoor environments and have much better access to certain areas of warehouses that were difficult to enter in the past, particularly loading docks. In fact, they’ll now be able to navigate these extremely active and unstructured environments down to the centimeter without any delay whatsoever. “We’re excited to join forces with Vecna…

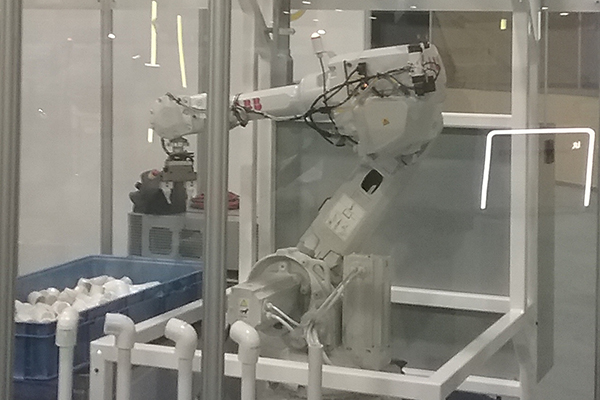

At a press conference on Tuesday, Universal Logic (Booth C2463) discussed two of its Neocortex G2R (goods-to-robot) cells, which are on display. One of the G2R cells (large) is exhibiting machine trending in manufacturing, while the other G2R cell (medium) is demonstrating the order fulfillment of consumer goods. Each G2R cell will be operating with Universal Logic’s Neocortex 5.0, an AI modular platform software that the company has been developing over the last 10 years. By using sensor data and machine control, the AI software provides the G2R cells real-time reactive control so they can handle upward of 90,000 SKUs—at…

As the processes, equipment and overall strategies of distribution centers and manufacturing plants are continuously responding to the ever-changing global marketplace, one part of the materials handling process has remained practically unchanged: dock equipment. However, a shift is occurring as DC and plant owners are beginning to focus on how to improve the effectiveness of their dock areas. To help employees as they transport products from docks to trailers, some companies are incorporating loading and unloading robotics. Others are focusing on their manual dock products by replacing yellow steel guard railings with new types of barriers and installing new dock…

On a daily basis, food and beverage distributors have a unique opportunity to contribute their knowledge and skills to one of the world’s most profitable and influential industries. The stakes are high though, and the consequences of errors can have a domino effect. One false move and a customer won’t receive their products on time. One miscalculation and the wrong products will get shipped. Not only will suppliers be delayed as they stock their shelves, but shoppers may be unable to purchase the goods they need. That can have a negative impact on the profit margins of the suppliers, as…