Editors’ Picks

Designing an autonomous commercial cleaning robots is no easy task and doing so in a timely fashion to capitalize on the growing demand for high-end cleaning systems makes the development timeline all the more pressing. To accelerate its time-to-market, robotics maker Avidbots has teamed up with Maplesoft to leverage the MapleSim advanced modeling software to design and test robots in a virtual simulation environment and cut back on physical testing. Making a useful digital twin By using Maplesoft MapleSim, Avidbots engineers were able to create a realistic digital twin model of its robot designers, providing flexibility to test out a…

CFD simulation is emerging as a critical tool to help combat the spread of COVID-19 and to help educate people how to ease back into normal routines, from taking mass transportation to safely sharing a meal with family and friends. Hexagon’s MSC Software has released an on-going series of simulations aimed at raising public awareness of the importance of social distancing and wearing protective coverings like masks. In its latest simulation, the company explores the impact of ventilation in social settings, specifically for a group dining together in indoor conditions. The simulation aims to replicate the physical behavior of airborne…

Simulation and data management are essentials for the development of any complex engineered product, perhaps even more so for autonomous and connected vehicles. To jumpstart development in this emerging category, Siemens Digital Industries Software has partnered with MaRS Discovery District, a Toronto-based innovation hub, to provide its member companies with access to Siemens’ Xcelerator portfolio of software. As part of the relationship, eligible companies will gain a year of free access to Siemens’ NX Mock3 CAD software, Simcenter PreScan simulation tools, and Teamcenter PLM platform. Within its ecosystem, the MaRS Discovery District hosts about 1,400 Canadian science and technology companies,…

When creating something as unique as the first un-crewed Ultimate Mobility Vehicle (UMV), it makes sense that an R&D team would take a novel approach to design. Hyundai Motor Group’s New Horizons Studio, established in late 2020 to draw on research from Silicon Valley and other innovation hubs to create a new class of intelligent mobility vehicles, is doing just that with its latest concept models. The studio is leveraging an on-going partnership with Autodesk to wield advanced technologies like generative design (GD) software and additive manufacturing (AM) to deliver TIGER (Transforming Intelligent Ground Excursion Robot), a concept vehicle announced…

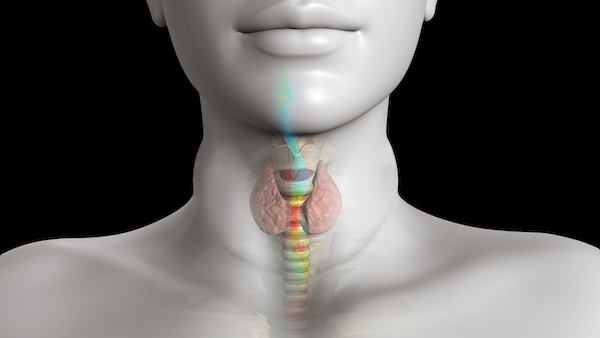

It’s now more common than not for simulation and modeling tools to spearhead early R&D efforts to explore, iterate and refine medical device designs while also serving as the means to create cheaper virtual prototypes. Less common, but equally promising, are nascent efforts to employ those same tools later in the process as a way to validate and test medical device prototype behavior in different patient scenarios for efficiency and safety. The next chapter is augmenting and potentially replacing expensive and lengthy animal and human clinical trials with simulation and modeling initiatives with an eye toward reducing costs, accelerating time-to-market…

After a months-long collaboration, RIZE Inc.’s 2XC desktop industrial 3D printer has achieved GREENGUARD Certification—a key safety and sustainability milestone for the printer—and also a marker that the firm’s RIZIUM Alliance can transform other existing Fused Deposition Modeling (FDM) offerings into safer options for mainstream use. Through its RIZIUM alliance, RIZE worked with partner Sindoh, a South Korean 3D printer manufacturer, to incorporate the RIZUM portfolio of materials into the 2XC and as a result, achieve GREENGUARD certification. In addition, the GREENGUARD certified RIZE 2XC model also supports the RIZIUM Carbon Filament material. The certification is a proof point that…

Want confirmation that additive manufacturing (AM) is fast evolving from an effective way of creating prototypes to a serious alternative for full-scale production? Essentium claims to have goods, touting the results of a recent independent study that shows use of large-scale AM more than doubling over the last year for 70 percent of participating companies. Highlights of the companies’ third annual study also found that the number of companies shifting to AM for full-scale production runs for hundreds, even thousands, of parts has doubled from 7% last year to 14% in 2020. The COVID-19 pandemic contributed to the rise in…

Siemens Digital Industries Software has filled in another piece in its Simcenter simulation portfolio, this time adding an Advanced Driver Assistance Systems (ADAS) data collection capability aimed at accelerating the development of autonomous vehicles. Through a partnership with b-plus, a maker of ADAR technology, the new Simcenter SCAPTOR offering combines hardware and software to record, visualize, and replay high-fidelity raw data along with a way to link that ADAS data to the central development process. Because ADAS and autonomous vehicles take over driving tasks that have traditionally performed by humans, they require massive amounts of data and AI-driven intelligence to…

There’s a long history of iconic pairings. Fred Astaire and Ginger Rogers still reign in the dance world, while peanut butter and jelly remains a favorite sandwich pairing for folks of all ages. In the digital world, relative newcomer generative design technology is increasingly being eyed as a complement to additive manufacturing (AM) with the outcome being new workflows that turn out game-changing products. Generative design tools, which include topology optimization and other artificial intelligence-based modeling techniques, burst on the scene these last few years as less expensive and more accessible computing power gives way to new algorithmic-driven design approaches.…

One of the many non-human casualties of the COVID-19 pandemic is the global supply chain, which has been seriously upended as economies shut down and fluctuating demand brought logistics and manufacturing to a screeching halt. One bright spot in the manufacturing and supply chain upheaval is additive manufacturing, which is fast emerging as an alternative way to produce key components at a local site while keeping the flow of goods in motion and the factory floor cycle intact. Strategic use of AM, experts say, can help manufacturers significantly reduce costs and transportation time while mitigating supply chain risks today, in…

Two startups, pioneering solutions in the additive manufacturing and blockchain technology arenas, are teaming up to offer an offering aimed at delivering trust to a new generation of on-demand spare parts produced as part of a digital supply chain. Data Gumbo, the provider of the GumboNet massively interconnected blockchain network, is working on a pilot project with Fieldmade, an Oslo, Norway-based company aiming to empower next-generation supply chains with on-demand production of spare parts using AM capabilities. Together, the partners are trying to shake up the way aerospace and defense and oil & gas supply chains have operated for the…

As with many technology initiatives, investment in 3D printing has not taken a hit this year despite all the business challenges related to the COVID-19 pandemic. That’s according to a new 3D Printing Trend Report published by MakerBot. Fueled by new materials (61%) and reduced costs (58%), respondents expect 3D printing use to grow over the next three to five years, in part to play a bigger role in the supply chain (49%) and to support localized manufacturing (46%). Nearly three quarters of respondents (74%) said they expect to invest in 3D printing over the next year while a little…