Editors’ Picks

Found in Robotics News & Content, with a score of 9.04

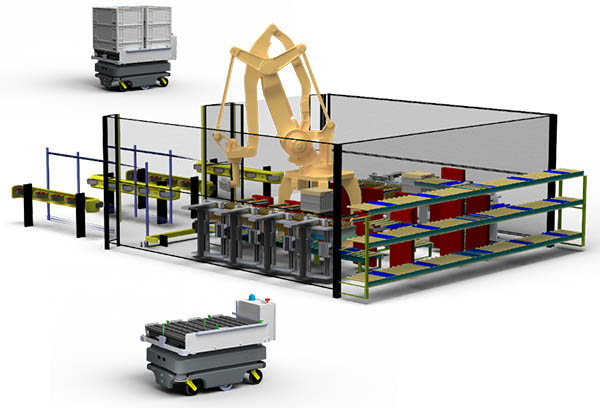

…General Motors, the U.S. Postal Service, United Parcel Service, Whirlpool, Jaguar Land Rover, and Caterpillar. Consumer goods are organized into sanitized totes to support a multiple gripper pick module that HDS Global said can achieve a 95% success rate. Source: Business Wire RoboFS taps talent for full automation To build the first fully automated fulfillment system and address fragmented e-commerce, HDS Global said it worked with “several innovative Global Fortune 500 heavyweights and industry veterans with bankable track records in robotics and e-commerce.” “Through the team’s collective insights, HDS Global has already refined the development of RoboFS into a production-ready…

Found in Robotics News & Content, with a score of 8.06

…piece of equipment up to warehouse robotics for a Whirlpool, Keurig Dr Pepper, or Thermo Fischer. We talked to customers about other equipment, including AGVs [automated guided vehicles], ASRS [automated storage and retrieval systems], and sortation systems. We then started to go to ProMat and MODEX, and we've built up a tremendous amount of knowledge about warehouse automation. We've heard from both vendors and customers that one barrier is upfront costs. We've built leasing structures to make payments and realize return on investment [ROI] over time. That way, customers can get instant savings from efficiencies. We're one of the rare…

Found in Robotics News & Content, with a score of 9.68

…L’Oreal; mobile robots in manufacturing at GE Healthcare and Whirlpool; a piece picking robot in order fulfillment at Rochester Drug; a collaborative mobile robot from Locus Robotics at Quiet Logistics, and robotic distribution at Medline. In the March issue of Modern, we are featuring DHL Supply Chain’s strategy for mobile robots in order fulfillment purposes, including its use of Locus. In fairness, you could argue that it’s probably been ten years since Kiva first exhibited at one of our trade events. How is this different? I think it’s different in two important ways. The first is the over-night emergence of…

Found in Robotics News & Content, with a score of 6.69

…items directly from shelves without human intervention. Finally, at Whirlpool, 54 robotic tuggers, each with a stereo camera-based navigation system from Seegrid, deliver washing machine parts to 24 locations on assembly and sub-assembly lines in Clyde, Ohio. This is just a glimpse of what’s to come on the mobile robot front, where Dwight Klappich, research vice president at Gartner, says we’re “on the cusp of some very radical changes to the warehouse thanks to automated robots.” And while warehouses and DCs have beenequipped with what Klappich calls “bolted to the floor” automation for nearly 40 years now, such equipment has…

Found in Robotics News & Content, with a score of 18.42

…the early adopters of Universal Robots Academy is the Whirlpool Corporation where the Universal Robots Academy modules now provide the basic foundation for all UR cobot training at the company’s plant in Ohio, USA. Tim Hossler, Controls Engineer at Whirlpool, emphasizes the great convenience of being able to offer this resource to employees in-house: “Now we don’t have to wait and send them out for basic training elsewhere. The modules can be completed at our own pace and we can even pick and choose which modules we offer different personnel depending on skill sets and their level of interaction with…

Found in Robotics News & Content, with a score of 22.46

At Whirlpool Corporation‘s 2.4-million-square-foot plant in Clyde, Ohio, a fleet of 54 blue robotic tuggers wind their way around the floor, automatically delivering parts every 20 to 30 minutes to some 24 drop-off locations on the assembly and sub-assembly lines. Operating in a three-shift, five-day-a-week operating environment, the mobile robots are a key component in the lean and continuous improvement philosophy in Clyde—billed as the world’s largest plant manufacturing top- and front-load washing machines. They are also an illustration of the company’s “smart automation” strategy, explains Jim Keppler, vice president of integrated supply chain and quality for the Benton Harbor,…