Editors’ Picks

Found in Robotics News & Content, with a score of 4.60

…affordable.” Rethink Robotics’ Ryder AMRs can be used to shuttle Reacher cobot arms from workcell to workcell, maximizing efficiency and ROI. Source: Rethink Robotics “One AMR can do fleet management for multiple production cells,” McEntyre said. Harbert added the robot arm and AMR portions of an MMR are usually bolted together and not easily separated. “Using a mobile robot and a robotic arm series that can work together and also separate and do their own jobs and then come back together - that is a really new concept,” he said. “It's difficult to set up the same robot arm in…

Found in Robotics News & Content, with a score of 12.51

…Vanderlande, according to the company. Hai’s portfolio complements Vanderlande’s shuttle-based ADAPTO automated storage and retrieval system (ASRS), which delivers exceptional storage density and throughput for high-performance fulfillment operations relied upon by the world’s largest brands, according to the companies. Hai Robotics’ ACRs bring a modular approach to warehouse automation applicable for both greenfield and existing warehouses. The system is also designed to be adapted with minimum disruption to ongoing operations, offering an appealing option for businesses who anticipate frequent or major changes over time. The robotic equipment operates within systems constructed of almost any standards racking, container type and size,…

Found in Robotics News & Content, with a score of 28.32

…operational efficiency with the implementation of Movu atlas pallet shuttles and a stow Racking silo. They combine to provide an automated system that can handle over 5,000 pallets of organic vegetables at -24°C (-11.2° F), ensuring reliable and efficient storage and retrieval processes year-round. The system achieves a throughput of 60 storage and retrieval operations per hour, meeting Westhof BIO’s goal of optimizing production and warehouse processes and delivering high-quality organic vegetables while making the best use of resources and reducing environmental impact. Germany's leading freezer, BIO-FROST Westhof GmbH is dedicated to processing exclusively certified organic vegetables. Its diverse range…

Found in Robotics News & Content, with a score of 4.75

…color and type to correctly route the ACOPS 6D shuttles to the IRB 360 FlexPicker to fulfill custom orders delivered to ACOPOStrak - all while maintaining high speed throughput, track and trace, and adaptability to last second order changes. ABB said its digital corner will highlight its suite of software tools that can take the time, effort, and complexity out of programming and operating robots - from RobotStudio to ABB’s new range of OmniCore robot controllers. ABB to celebrate 50 years of expansion and education ABB said its investment in AI, including the recent acquisition of Sevensense, an AI-enabled 3D…

Found in Robotics News & Content, with a score of 6.99

…and cybersecurity capabilities. Berkshire Grey’s robotic systems include robotic shuttle put walls, sortation systems, and pick cells, which can automate repetitive, manual processes like item sortation for returns or store replenishment and picking. Honeywell said when coupled with its robotics integration knowledge, these systems offer customers improved throughput capacity, labor efficiency and order accuracy. “Order fulfillment, along with stocking shelves, can be some of the most expensive and labor-intensive processes for retailers,” said Keith Fisher, President of Honeywell Intelligrated. Berkshire Grey's automated solutions combined with Honeywell's intelligent software and integration experience enable businesses to accomplish these tasks in a fraction…

Found in Robotics News & Content, with a score of 51.14

HWArobotics showcased its shuttle automated storage and retrieval systems (ASRS) technology at MODEX 2024 in Atlanta. The Singapore-based warehousing and logistics robot company has 20 years’ experience in developing and building shuttle robot systems. HWArobotics is looking to expand its customer base in the North America region and develop new partnerships with distributors, following its shuttle system deployment by Canadian 3PL business Darwynn. HWArobotics launched four product lines at MODEX, including three tote shuttles, one pallet shuttle and associated cargo lifts, racking and control software. The customizable shuttle robot systems deliver high throughput for a wide range of industry sectors…

Found in Robotics News & Content, with a score of 13.09

…end-to-end automation systems combine gantry robots, intelligent software, automated storage and retrieval systems (AS/RS), automated guided vehicles AGVs, conveyors, shuttles, and palletizers. Cimcorp offers end users continuous maintenance services, including spare parts, training, and 24/7 support, to help its customers secure a lifecycle of 20 years or more for their automation technology.

Found in Robotics News & Content, with a score of 9.24

…general, even outside of reverse logistics. Our automated Robotic Shuttle Putwall (RSPW) was designed to be able to handle shoe boxes. That system can handle those shoe boxes irregardless of whether that's for fulfillment, a distribution operation, or a reverse-logistics operation. Berkshire Grey's Robotic Shuttle Putwall (RSPW) can sort small boxes and items in poly bags to expedite reverse logistics workflows. Source: Berkshire Grey. Returning apparel and e-commerce products to market quickly Are there particular industries or areas where Berkshire Grey's product deployments have been most successful? Geyer: In the apparel space we've had a lot of success, especially in…

Found in Robotics News & Content, with a score of 24.54

…goods-to-person AS/RS installed at Darwynn’s facility as a multi-level shuttle system with 24 carts, 6 cart elevators, and 10,368 storage locations. During the first phase of Darwynn’s project, storage was configured as 3 double-deep aisles with 8 levels enabling parallel operation of multiple shuttle carts. The system included picking stations and WCS systems. AS/RS system’s inventory capacity totals 200,000 items Darwynn was looking to meet the demands of its business expansion as the number of SKUs within its facilities increases. The company’s Toronto facility handles 20,000 individual SKUs. HWArobotics said the system's total inventory capacity is 200,000 items. HWArobotics said…

Found in Robotics News & Content, with a score of 11.26

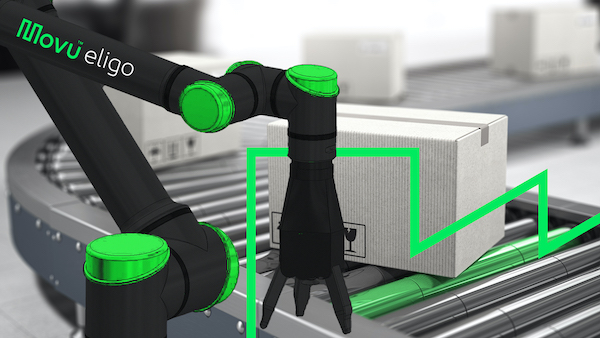

…sub-system that is integrated with the Movu escala bin shuttle, resulting in an innovative end-to-end automated solution from storage to picking; Easy way to automatically pick SKUs that are suited for robotic picking, store the bins, and then finish the order with a manual pick when the time is convenient; Reduced cost per pick resulting in a strong Return on Investment (ROI). Provided with seamless integration as a pick station option for the Movu escala bin shuttle, the Movu eligo combines advanced software with intelligent grippers and machine vision to ensure reliable throughput. The robot will gently grasp an item…

Found in Robotics News & Content, with a score of 14.50

…Robotics' warehouse automation portfolio includes the Movu atlas pallet shuttle, the Movu escala bin shuttle, and the Movu ifollow autonomous mobile robot (AMR) for pallet transport or collaborative picking. It also includes the new Movu eligo integrated robot arm, which is offered as a picking workstation for escala. stow Robotics acquired iFollow SAS last year, in addition to Raiser Robotics in 2021. In addition, the company offers load carriers and its own warehouse execution software (WES) to control and manage all of these systems. Customers can “gain the key advantage of seamless integrated racking and robotics,” said Movu. The broad…

Found in Robotics News & Content, with a score of 18.68

…demonstrate that point, according to Exotec. Take a traditional shuttle system as an example. These systems typically consist of shuttles dedicated to specific aisles and a series of elevators and conveyors that help move goods between multiple levels in an aisle and eventually get them to warehouse associates. This complexity puts stringent limitations on the system, especially when it comes to the flexibility of the ASRS. For instance, scaling a shuttle system could involve significant modifications to the existing infrastructure, costing time and money, said the company. In addition, if a single point of this system fails—such as an elevator—then…