Editors’ Picks

Found in Robotics News & Content, with a score of 65.32

…manufacturing even easier thanks to a new collaboration with nTopology, innovator of next-generation design and engineering software. The two companies are providing a series of accessible, customizable design for additive manufacturing workflows for their users, starting with the FDM Assembly Fixture Generator. Stratasys FDM printers have become powerful, supporting advanced materials like Nylon 12 Carbon Fiber and reaching accuracy and reliability required for use on commercial airplanes and even the International Space Station. But designing with existing engineering software tools still creates long lead times, slowing additive manufacturing's march to pervasive adoption. The new Stratasys | nTopology collaboration incorporates the…

Found in Robotics News & Content, with a score of 43.67

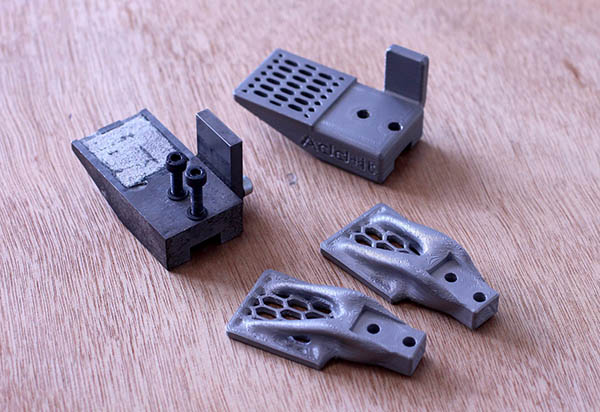

…help of Additive Italia SRL, Desktop Metal Inc., and nTopology Inc. Preziosa Francesco realized that CNC machines would require long lead times to create new grippers for its existing robotic cell and automated press bending machine. The company worked with design engineers from Additive Italia (Add-it) to move part production in-house, and it used nTopology's software for topology optimization. “A small part was reducing the value of the robot,” said Duann Scott, vice president of business development at nTopology. “By optimizing a small, inexpensive component, we helped unlock its full potential.” nTopology complements CAD “They came to us with the…

Found in Robotics News & Content, with a score of 20.09

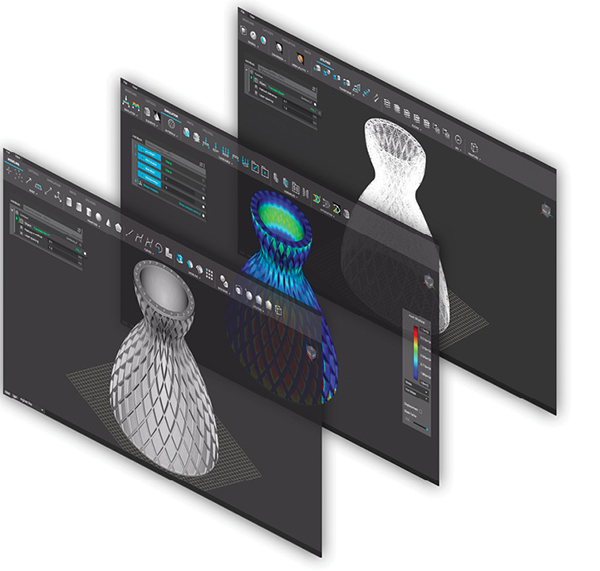

…for advanced manufacturing techniques, including 3D printing. The three-year-old nTopology just released nTop Platform, a computational-based offering that integrates CAD, simulation, and computer-aided manufacturing (CAM) capabilities to help engineering teams create complex and optimized geometries that are difficult or impossible to make with traditional offerings, according to Bradley Rothenberg, the company’s founder and CEO. “The shift to advanced manufacturing is the driver that’s allowing us to innovate new engineering processes,” Rothenberg says. “We can make parts with unprecedented complexity,” and allow for the design and material composition of a part to be handled in the same system and workflow, he…

Found in Robotics News & Content, with a score of 19.83

…OptiStruct,” Dias adds. Checkboxes vs. Templates Founded in 2015, nTopology is a relative newcomer to the design software sector. “Manufacturing constraints have been in our product from day one,” says Brad Rothenberg, cofounder and CEO. One of nTopology’s appeals is its software’s ability to generate complex lattice and membrane-like structures, a useful feature for lightweighting projects. “It was important for us to make sure these lattice structures are manufacturable,” says Rothenberg. At its debut, nTopology focused its attention on nTopology Element, a point-solution for generating lattice structures. As the company grew, it developed and released nTopology Platform, a digital design…

Found in Robotics News & Content, with a score of 16.67

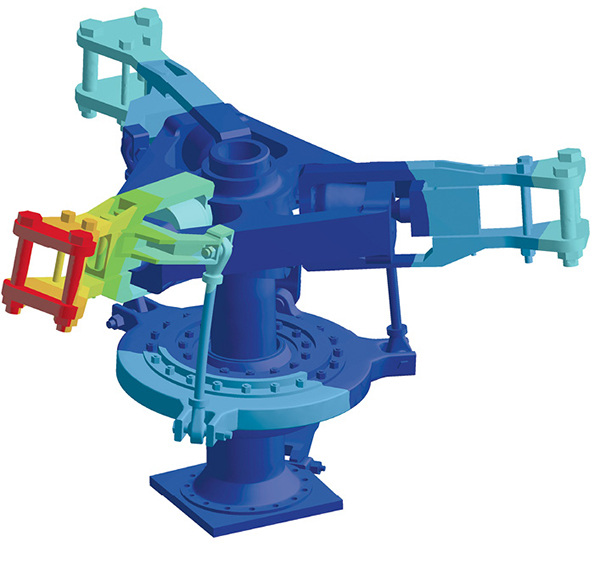

…unit cost. Using the nTop generative design platform from nTopology in concert with VELO3D’s Sapphire metal 3D printer, the design team was able to consolidate 61 parts into a single part, reducing the number of joints between parts, thus minimizing the number of seals and fasteners and extending service life as well as flaws that could degrade engine performance. Sierra Turbines could never have achieved this level of performance benefits using traditional design and manufacturing processes, contends Brad Rothenberg, nTopology’s CEO. “When you’re implementing advanced manufacturing, you don’t get value from taking a design meant for traditional manufacturing processes and…

Found in Robotics News & Content, with a score of 16.54

…platform: Authentise, Additive Flow, Ecochain, iPoint, Neural Concept and nTopology. The companies have joined forces over the past three months to co-develop a digital additive manufacturing workflow that translates customers’ needs into manufacturing solutions. Purpose of the Platform The purpose of this digital platform is to leverage application, material and processing knowledge to inform manufacturers about the performance, sustainability and economic viability of additive manufacturing for their specific applications. The companies have focused on a workflow that supports manufacturers in the screening, design and simulation steps prior to the actual printing of a part. In doing so, the I AM…

Found in Robotics News & Content, with a score of 7.01

…trend of adding topology optimization to CAD workflows. Frustum, nTopology and ParaMatters differ in the details of how they optimize design, but all three use GPUs and AI-based processes to solve hundreds or hundreds of thousands of design alternatives in what generally is a real-time process. “Frustum has no legacy [in CAD’s CPU-based history], so we get to think about how to fully utilize GPUs from the start,” says Jesse Blankenship, the founder and former CEO of Frustum, which was acquired in late 2018 by PTC. “Bringing AI and design optimization to designers makes it an interactive process, just like…