Editors’ Picks

Found in Robotics News & Content, with a score of 0.92

…equip students with the foundational, real-world skills needed as manufacturing continues to evolve. Named after the popular open-source Arduino platform and development partner ASTOR, Astorino leverages Kawasaki Robotics’ technology expertise, including hardware, firmware, control system, application software and training. The platform also supplies STL files so students can rapidly print 3D replacement parts for 99% of the robot. Affordable platform enables low student-to-equipment ratio At the core of Astorino is a 1kg payload, 6-axis robot with a structure and programming environment nearly identical to that of a Kawasaki industrial robot. Weighing only 12 kg and powered by a 110V outlet,…

Found in Robotics Companies & Businesses, with a score of 14.22

…and general industries. Driven by decades of experience in manufacturing, the company focused on creating industry-leading robots that they would want to use in their own factories. Now, Kawasaki Robotics is known for producing high-quality industrial robots that stand the test of time as manufacturing evolves. Kawasaki Robotics produced the first commercial industrial robot in Japan in 1969. Since then, the company hasn’t stopped developing state-of-the-art technology while diversifying its product line, drawing from years of automation experience and deep roots in manufacturing. In addition, the innovative engineering and customer-focused service teams continue to raise the bar, resulting in a…

Found in Robotics News & Content, with a score of 3.24

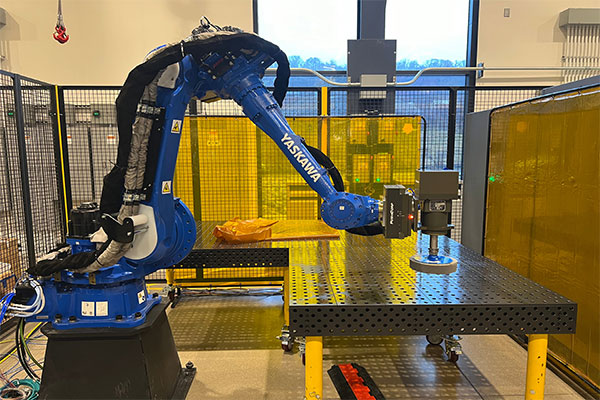

…FANUC America, recently introduced Alchemist 1, an all-in-one additive manufacturing robotic workcell. The cell is made in the USA and was engineered for easy integration and rapid deployment. Large scale, dense metal parts Powered by Meltio’s Wire-Laser Metal Deposition (W-LMD) technology, Alchemist 1 delivers cost-effective production of large, fully dense metal parts, catering to the needs of automotive, aerospace, mining, oil and gas, and various other sectors. Some key features of the Alchemist 1 include: A deposition rate of up to 1 kg an hour A build volume of 3.2’ x 6.5’ x 3.2’ And compatibility with inexpensive welding wire…

Found in Robotics News & Content, with a score of 0.97

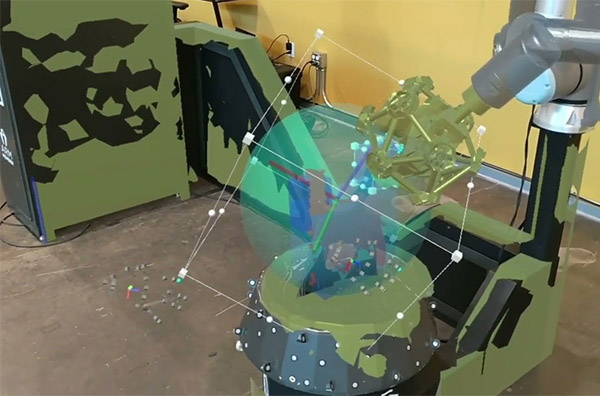

…the capabilities of AutoStore robotic cube storage systems for manufacturing customers. FulfillX can optimize picking and packing, while also streamlining putaway and other inventory processes. It provides a real-time overview of a whole operation in a simple window. Enhancements can be deployed by Kardex’s dedicated AutoStore support team, and digital twins enhance planning and commissioning. As well as promoting FulfillX, Kardex’s booth also used digital tools and augmented reality simulations to bring to life its range of smart intralogistics solutions including Intuitive Picking Assistant. Kardex said its Intuitive Picking Assistant is suitable for a wide range of industrial manufacturing applications,…

Found in Robotics News & Content, with a score of 2.92

The Advanced Robotics for Manufacturing (ARM) Institute recently announced that three consortium member projects were selected from over 100 proposals submitted to the Office of the Secretary of Defense (OSD) Manufacturing Technology (ManTech) Organic Industrial Base (OIB) Modernization Challenge held earlier in 2024. The ARM Institute is a DoD Manufacturing Innovation Institute and a member of the Manufacturing USA Network. Providing resources for U.S. manufacturers that utilize advanced robotics and AI, the Institute connects more than 400 member organizations across industry, government and academia. OIB process took over a year before selection The OSD ManTech Program hosted representatives from five…

Found in Robotics News & Content, with a score of 4.73

The Advanced Robotics for Manufacturing (ARM) Institute recently announced a continuation of its public-private cooperative agreement with the Department of Defense (DoD) Manufacturing Technology Program. The $35.4 million agreement will continue ARM Institute’s funding as a national Manufacturing Innovation Institute for through 2028, with an option to renew the contract again for another five years. If the DoD accepts the further renewal offer, ARM Institute's total possible primary investment increases to $70.4M over 10 years. The Institute’s original agreement with the DoD provided funding through January 2023. Following a successful review by the DoD Joint Defense Manufacturing Council (JDMC) in…

Found in Robotics News & Content, with a score of 3.55

The Advanced Robotics for Manufacturing, or ARM, Institute last week said that it has evaluated and selected seven more training programs to endorse. The ARM Endorsement Program is a thorough evaluation process intended to identify the organizations that most effectively prepare students for careers in manufacturing working with robots. “Millions of manufacturing jobs may go unfilled in the coming years if we do not work to correct the manufacturing workforce gap,” said Lisa Masciantonio, chief workforce officer at the ARM Institute, in a release. “Effective training programs are critical to course-correcting, engaging the next generation of manufacturers, and helping to…

Found in Robotics News & Content, with a score of 1.78

…International Inc. today announced a strategic partnership with Intellistore USA, an intralogistics and automation provider. Intellistore will join ResGreen’s distribution network, selling, integrating, and installing its storage systems with ResGreen’s software and mobile robots. Intellistore plans to integrate its automated storage and retrieval systems (ASRS) with ResGreen’s open-architecture BotWay software, automated guided vehicles (AGVs), and autonomous mobile robots (AMRs). “We are excited to add Intellistore to our expanding list of distributors,” said Parsh Patel, CEO of ResGreen, in a release. “The company’s employees are dedicated to introducing our leading-edge, AI-based solutions to its extensive customer base.” “The partnership showcases our…

Found in Robotics News & Content, with a score of 4.58

ASTM International this week said that the Advanced Manufacturing Robotics, or ARM, Institute has awarded it funding to develop a roadmap for guidance and adoption of advanced robotics technologies. In partnership with the institute, ASTM also plans to host its 4th Specialty Workshop on Discovery & Market Analysis for Robotics in Manufacturing of Space and Hypersonic Components. The workshop will be on Oct. 4 and 5, 2023, at ASTM headquarters in West Conshohocken, Pa. Interested parties are required to register their interest in attendance. The main goals of the workshop, which the ARM Institute funded in a recent project call,…

Found in Robotics News & Content, with a score of 3.37

The Advanced Robotics for Manufacturing, or ARM Institute today announced that it will award a total of $3.26 million across eight new projects that identify challenges facing U.S. manufacturers and propose technology solutions. The institute said it has funded and managed more than 150 robotics, artificial intelligence, and workforce development projects to date. “Our selections in this latest project call address diverse areas of need in manufacturing – from identifying and road-mapping needed robotics developments to directly creating solutions for the problems that manufacturers are facing today,” stated Dr. Chuck Brandt, chief technology officer of the ARM Institute. “These projects…

Found in Robotics News & Content, with a score of 1.18

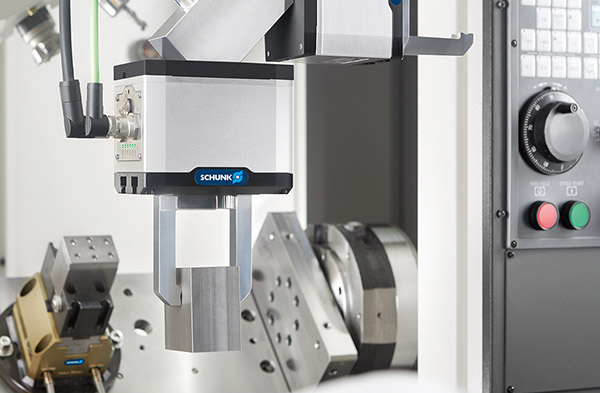

…its full potential,” stated Milton Guerry, president of SCHUNK USA, on LinkedIn. “Whether investigating automation possibilities for the first time, or re-deploying automation equipment for a new task, Automation Explorer brings major opportunity for understanding automation process potential while also digitalizing and simplifying deployment tasks.” SCHUNK, whose U.S. offices are in Morrisville, N.C., is a leader in tooling, gripping, and automation technologies. The family-owned company said it has about 3,500 employees in eight plants and 34 directly owned subsidiaries and distribution partners in more than 50 countries. Automation Explorer to provide realistic experience “Automation Explorer will take the term 'digital…

Found in Robotics News & Content, with a score of 0.19

…each month and record-high turnover numbers. More than 100,000 manufacturing jobs were unfilled for U.S. consumer packaged goods (CPG) companies as of July 2022, according to a recent Consumer Brands Association (CBA) analysis of U.S. Bureau of Labor Statistics data. The result of these job vacancies is slowed production and stagnant growth. It also means employee retention is key. Robotics and automation are not only helping to fill the labor gap, but they also help make traditionally undesirable jobs easier and safer. “We’re never trying to displace anyone in a facility, as much as empower a company to repurpose staff…