Editors’ Picks

Found in Robotics News & Content, with a score of 59.51

Fictiv has closed a $33 million Series C funding round to accelerate its transformation of contract manufacturing into a global digital ecosystem that enables fast, flexible hardware product development and production. Led by G2VP, with new investor Mitsui & Co. joining return partners Accel, Bill Gates, Intel Capital, Sinovation and Tandon Group, the round brings Fictiv’s total investment to $58 million. Fictiv will use the funds to accelerate its work to digitize and automate the manufacturing workflow. Core initiatives for the company include: investment in its cloud infrastructure and software tools to streamline workflow, expansion of its global manufacturing network…

Found in Robotics News & Content, with a score of 57.82

Fictiv has established a new collaboration that adds Jabil Inc. as a key part of its global manufacturing network to connect and streamline 3D print prototyping through to mass-scale production using an innovative digital thread. Designed to de-risk and streamline the supply chain through quality, speed, transparency and flexibility, the thread is built to ensure a supported customer experience from quote to completion, the companies report. “We know from years of manufacturing experience that the move from idea to volume consumption is hard – no matter how solid the products are. Our goal is to add speed and agility to…

Found in Robotics News & Content, with a score of 51.81

In July, on-demand manufacturing service provider Fictiv released its 2020 State of Manufacturing Report, revealing the extent of COVID 19's impact on the industry. According to Fictiv's data: eighty nine percent (89%) report a direct business impact because of COVID-19 including lower sales, increased costs of materials and production, and canceled or delayed product launches; only 17% gave top marks to their supply chain’s performance over the last year; a majority are revisiting their reliance on China and looking to the U.S. as the next key manufacturing center; nearly all (97%) said COVID-19 has created new opportunities, with 87% making…

Found in Robotics News & Content, with a score of 50.77

Fictiv has unveiled features that deliver visibility, traceability, speed and quality benefits for customers leveraging its Digital Manufacturing Ecosystem (DME) to order high-tolerance, custom mechanical parts for prototyping and production needs. In response to evolving customer work-from-home requirements as well as more compressed new product introduction timelines, Fictiv’s new radical transparency initiative helps introduce risk mitigation and cost-savings opportunities. The impact for enterprise companies trying to orchestrate production of hundreds of parts at once is enormous. “These new features on Fictiv’s platform are incredibly useful,” says Antonio Ruiz, supervisor, Strategic Sourcing at NASA’s Jet Propulsion Lab. “Having 24/7 visibility and…

Found in Robotics News & Content, with a score of 49.61

Manufacturing ecosystem Fictiv announced that hospitals and healthcare providers can begin ordering the protective face shields in batches of up to 10,000 per order at cost for shipment as fast as one day. The company is leveraging its global manufacturing network and a newly designed tool to produce millions of face shields available in the fight against COVID-19. Fictiv has invested in the upfront tooling costs to make the shields available as quickly and easily as possible to healthcare agencies, service providers, distributors and even non-healthcare OEMs that are pivoting to support the healthcare industry during this crisis. The pricing…

Found in Robotics News & Content, with a score of 49.16

Fictiv Inc. today announced that it has closed a $100 million Series E funding round. The San Francisco-based company said it will use the investment to accelerate product innovation and expand its focus on reducing supply chain risk by virtualizing complex manufacturing workflows. “We're grateful for this outstanding support from our investment partners,” said Dave Evans, CEO of Fictiv. “We plan to leverage this new capital to accelerate our investment in our customers’ top challenges, particularly time to market for new products and supply chain risk and geographic resilience, through increased collaboration across organizations with reliable, transparent sourcing workflows.” Fictiv…

Found in Robotics News & Content, with a score of 41.69

Fictiv released its fourth annual State of Hardware Report, highlighting the added burden of tariffs on an industry working to quickly and affordably bring products to market, according to Fictiv. The data-driven insights from this year’s survey found that companies across America, from large enterprises to small startups, have faced heavier supply chain and resource constraints when trying to get to market as a result of tension between the U.S. and its trade partners, Fictiv reports. To compensate, product development teams said they are leveraging multiple tariff engineering tactics to bypass manufacturing obstacles and create more agile supply chains. Findings…

Found in Robotics News & Content, with a score of 30.23

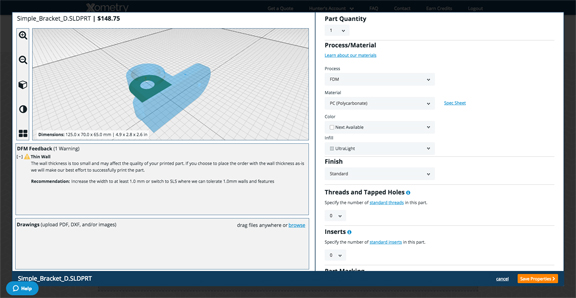

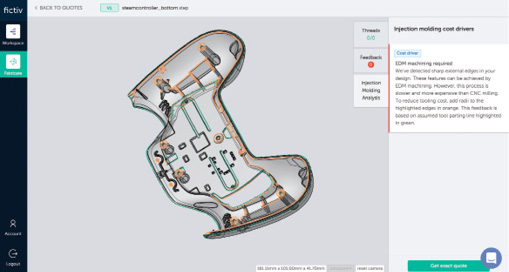

…through Xometry's platform moving forward,” explained Cronin. San Francisco-based Fictiv, also an on-demand manufacturing service provider, uses a similar online interface for file submission and quote request. The convenience of online file-based ordering has evidently attracted not just small firms but many major household names in consumer goods and manufacturing. Xometry has worked with “BMW and 44% of the Fortune 500 motor vehicles and parts companies,” according to its web site. Fictive's customer list includes NASA and Ford, among others. With both Xometry and Fictiv, the highly automated ordering system manages the file transmission, inspection, and job quote requests. But…

Found in Robotics News & Content, with a score of 27.06

From the outset, what Fictiv and Xometry appear to do is no more than matchmaking. It’s the principle pioneered by tech disruptors such as Airbnb, applied to manufacturing. Airbnb matches those seeking short-term living accommodations with those who happen to have extra space that can accommodate travelers. Thus, a whole new ecommerce infrastructure was born to satisfy the backpackers and budget-conscious travelers who previously didn’t have an option; and the homeowners who previously didn’t have a good way to offer their extra bedrooms and vacation homes for rental. Similarly, manufacturers with extra production capacity can join the Fictiv and Xometry…

Found in Robotics News & Content, with a score of 22.49

…must compete with younger but earlier players like Xometry, Fictiv and Protolabs. Some of these companies started out as portals catering to the inventors and hobbyists with low-volume orders that traditional manufacturers would rather ignore than fill. Others began by providing a single type of production. But many have outgrown their humble origins over time. Fictiv was founded in 2013, a mere 6 years ago, but last May, after securing U.S. $15 million in Series B funding, the company opened a China-based division and launched its Agile Manufacturing Solution (AMS), which expanded Fictiv’s product offering beyond prototyping into production volume…

Found in Robotics News & Content, with a score of 14.64

…used us before,” recalls Paulsen. Headquartered in San Francisco, Fictiv also relies on its network and automated quoting system to offer on-demand manufacturing service. “Businesses that could adapt fast and were digitally enabled could survive the disruptions and even thrive by supporting the need for test swabs and other rapid response solutions for the frontline fight against COVID,” says Dave Evans, co-founder and CEO of Fictiv. “It has been a chance for both 3D printing and digital manufacturing ecosystems to show why they are so important to the future of manufacturing and [the] supply chain.” Eventually the danger of the…

Found in Robotics News & Content, with a score of 7.23

…in what is clearly an outdated and unreliable model,” Fictiv’s Dave Evans writes in Forbes. “In a world where markets and supply chains are global, there must be a better way.” A Better Way By blending good inventory management strategies with the ability to move inventory quickly throughout the supply chain at a high velocity and lower cost, companies can ensure that the right products are in the right place and at the right time. Using a combination of hardware and software, companies can achieve this balance in any environment. The PINC AIR Aerial Inventory Robot™, for example, allows companies…