Editors’ Picks

Found in Robotics News & Content, with a score of 65.32

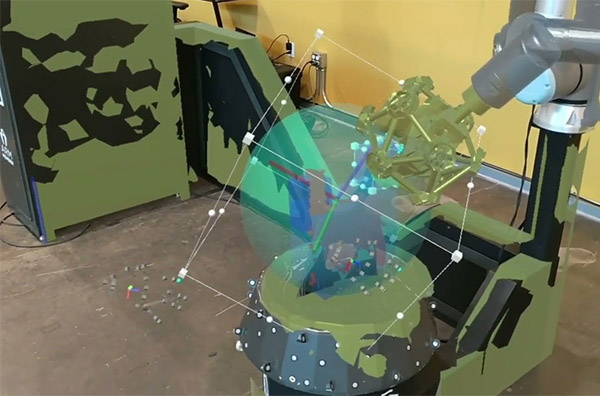

CapSen Robotics, a Pittsburgh-based company that produces 3D machine vision and motion planning software for robotic bin-picking applications, recently introduced the v2.0 release of its CapSen PiC software. The system features a new user interface (UI) and programmable AI designed to tackle challenging high-mix, low-volume bin-picking tasks. CapSen PiC 2.0 made its debut at Automate 2024 in Chicago in the Pittsburgh Robotics Network booth. Motion planning through 3D vision CapSen PiC v2.0 combines 3D vision, motion planning and control algorithms to provide robots the ability to locate, pick and manipulate objects from cluttered bins and shelves. The system accurately detects…

Found in Robotics News & Content, with a score of 60.65

CapSen Robotics today announced the official v1.0 release of its CapSen PiC system. The Pittsburgh-based company claimed that it can turn “any industrial robot arm into a robotic workcell designed to tackle today’s most challenging pick-and-place applications.” “Tasking a robot with making high-speed, accurate picks of parts presents several challenges, including the fact that parts can be randomly piled in containers, stacked on top of one another, or even entangled,” said Jared Glover, CEO of CapSen Robotics. “CapSen PiC takes aim at the most challenging bin-picking problems by combining 3D vision with advanced motion planning and control software to give…

Found in Robotics News & Content, with a score of 52.18

PITTSBURGH—For the past several months, CapSen Robotics has been gearing up for Automate, the Association for Advancing Automation's robotics trade show in Detroit. The Pittsburgh-based startup develops software for robot arms and has partnered with DENSO and Calvary Robotics to showcase its CapSen PiC System, which was designed to help customers program their robots to complete bin-picking tasks. “We do software for adding intelligence to robot arms,” Jared Glover, CapSen Robotics CEO and co-founder, told Robotics 24/7 during a recent visit to its headquarters. “We provide all the 3D vision software and the motion planning and control software to get…

Found in Robotics News & Content, with a score of 37.01

…Institute today announced that Dr. Jared Glover, CEO of CapSen Robotics, has been selected as the institute’s first fellow. As an ARM Institute Fellow, Glover will execute a technical project to address key challenges hindering the adoption of robotics in manufacturing. The new fellowship program supports the Artificial Intelligence in Metals and Manufacturing (AIM) Higher Consortium. That group is led by the Catalyst Connection and is intended to help small and midsize manufacturers that supply or are pursuing opportunities with the U.S. Department of Defense (DoD). First ARM Institute Fellow Glover is co-founder and CEO and of CapSen Robotics, which…

Found in Robotics News & Content, with a score of 20.57

…Robotics Venture Fair: AdSkate Aquatonomy Beyond Reach Labs BlastPoint CapSen Robotics CellX Technologies FlowCellutions Fluid Reality Humotech Journey Robotics Moss Robotics Rockfish Data Shelfmark Sitewiz TeraSpatial Thiopoly Velo AI X-Hab 3D Companies such as BlastPoint, Roadbotics and PredxBio (formerly SpintellX) have participated in previous versions and attracted investors to Pittsburgh’s rich startup ecosystem. “Pittsburgh’s rich history of innovation and its community of researchers and entrepreneurs create the ideal setting for the AI & Robotics Venture Fair,” said Dave Mawhinney, founding executive director of the Carnegie Mellon Swartz Center for Entrepreneurship. “This event introduces groundbreaking advancements but also reinforces our city’s…

Found in Robotics News & Content, with a score of 10.74

…selections. In May, it named Dr. Jared Glover from CapSen Robotics as its first fellow. Applications are due at 5:00 EST on Dec. 3, 2021. All information must be submitted via the email to the [email protected]. The ARM Institute will fund multiple fellows throughout the course of the AIM Higher Consortium agreement, which ends in September of 2023. The institute has identified the following criteria and guidelines for submission: Winning fellows will be expected to propose full-time projects for periods of up to 1 year. ARM will award up to $60,000 per fellow. Funds cannot be used to purchase equipment.…

Found in Robotics News & Content, with a score of 10.56

…In 2021, the institute selected Dr. Jared Glover from CapSen Robotics as its first fellow. The ARM Institute recently announced a call for projects to advance AI and robotics for manufacturing. The AIM Higher Consortium is led by the Catalyst Connection and is funded by the U.S. Department of Defense through the Office of Local Defense Community Cooperation (OLDCC)’s Defense Manufacturing Community Support Program. The consortium seeks to strengthen the defense supply chain in the Greater Pittsburgh region of Southwest Pennsylvania and West Virginia. AIM Higher exists to support small and midsize manufacturers that currently support or are actively pursuing…

Found in Robotics News & Content, with a score of 9.21

…finishing of castings through parting line grinding Principal investigator: CapSen Robotics Project Team: The Ohio State University, Southwest Research Institute, and Yaskawa Motoman Description: Metal casting offers considerable flexibility in a component’s size, shape, and material and often operates in the low volume, high mix manufacturing regime. Castings often have highly variable features/defects that need to be removed or post-processed. Finishing processes today are typically completed manually due to variability. These manual processes can lead to errors, higher costs, and slower speeds. This project team will develop a robotic finishing cell that autonomously finishes castings. The system will image the…

Found in Robotics News & Content, with a score of 8.98

…Metal Forming Lead: The Ohio State University Partners: Yaskawa, CapSen Robotics Description: The project team will address the challenge of low-volume, high-mix production of complex metallic components. Metallic components are commonplace in the commercial automotive sector; high-end auto sports; heavy-duty factory machinery; power plants; and in air, land, and sea-based military equipment. When replacement components are needed, particularly for aging systems, quality, cost, and lead-time are often unable to be balanced for an acceptable solution. The team will design and deploy an AI robotic system capable of flexibly producing a myriad of component geometries in a timely and cost-effective manner.…

Found in Robotics News & Content, with a score of 7.22

…Phase 2 Project team: Ohio State University (principal investigator), CapSen Robotics, Yaskawa, and Warner Robbins Air Force Base Topic areas addressed: AI in robotics for manufacturing Description: This project builds on the outputs from the previously funded ARM Institute Autonomous Robotic Metal Forming project. There is a growing need for small-volume, high-mix manufacturing, such as in cases of manufacturing replacement components for aging systems or personalized medical implants. However, there is a limited supply chain for one-off components, and complex components require expensive machining and/or tooling and dies. This project seeks to drastically accelerate the productivity of the robotic system…

Found in Robotics News & Content, with a score of 7.09

…getting faster and more accurate, with less AI overhead. CapSen Robotics, Mujin, and Soft Robotics provided some examples. Most of the collaborative robot suppliers showed welding cells, with Universal Robots leading the way with its first cobot TIG welding and spot welding applications with partners THG Automation and Pro Spot, respectively (see video below). Kane Robotics and FerRobotics used a UR cobot to demonstrate grinding and surface finishing (see photo, top right). Affordability and ease of use were important, as igus demonstrated with its low-cost automation line at Automate. The motion plastics supplier openly listed the prices for all its…

Found in Robotics News & Content, with a score of 6.68

…Team: University of Southern California, Carnegie Mellon University, and CapSen Robotics Project Description: This project seeks to build a configurable robotic system for fixtureless and dynamic high mix/low volume (HMLV) manufacturing that identifies/inspects assembly parts, autonomously plans motion and tasks, and optimizes human collaboration with the robotic manufacturing cell. By eliminating fixturing, this project enables rapid cell repurposing and reduces production costs. To reinforce cell agility and throughput, task planners will take in high-level assembly instructions and decompose tasks between humans and robots based on operation complexity. Hierarchical Robot Learning Framework Based on Reinforcement Learning for Decision Making and Control…