Editors’ Picks

Found in Robotics News & Content, with a score of 1.29

…over a potential competitor.” Employees at Aircraft Tooling Inc. (ATI), a Dallas-based repair center for the aviation industry also attending the event, said they were surprised to find that a collaborative robot could withstand a harsh environment while performing plasma spray processes. The system has freed them from that task. While the the cobot eventually “won their hearts,” employees were initially uncertain as to whether the robot would operate reliably in the spray booth’s extremely hot and dusty environment, said Juan Puente, thermal spray supervisor at ATI. “We were very surprised,” he said. “I thought the robot wouldn’t stand it.”…

Found in Robotics News & Content, with a score of 12.47

ATI Industrial Automation Inc. today announced the MC-50 Manual Tool Changer, which it claimed “provides unmatched performance, reliability, and quality for the manual exchange of robotic tooling.” The patent-pending MC-50 has an intuitive design and ergonomic lever operation to enable fast changes of robotic end-of-arm tooling (EOAT) by hand, said the company. It also includes a safety latch button on the lever to provide secondary locking for increased safety and prevention of involuntary uncoupling, ATI noted. MC-50 designed for compatibility, endurance The MC-50 is designed for safe, diverse use cases. Source: ATI Industrial Automation The compact Tool Changer is intended…

Found in Robotics News & Content, with a score of 12.10

ATI Industrial Automation today announced that its Multi-Axis Force/Torque Sensors are compatible with FANUC's robots and Force Control Software. “This collaboration opens up new possibilities for advanced automation and precision control in robotic applications,” said the Apex, N.C.-based company. “This collaboration brings together two industry-leading solutions, enabling our customers to achieve new levels of dexterity, efficiency, and reliability in their robotic applications,” said Robert Little, president and general manager of ATI Industrial Automation, in a release. ATI Industrial Automation claimed that it is “the world’s leading engineering-based developer of robotic accessories and robot arm tooling including multi-axis force/torque (F/T) sensing…

Found in Robotics News & Content, with a score of 8.40

Ati Motors today announced that its Series A funding round has closed at $10.85 million (U.S.). The Bengaluru, India-based company said the investment will further accelerate the development and deployment of its robots for warehouses and industrial environments. “The autonomous robots space is brimming with immense opportunities, and we’re at the forefront of this revolution as we transform industrial operations,” said Saurabh Chandra, CEO of Ati Motors. “This funding will fuel our expansion into new markets and industries. With the support of our investors who share our vision, we’re well-positioned to continue pushing the boundaries of robotics technology and meet…

Found in Robotics News & Content, with a score of 3.83

ATI Industrial Automation yesterday announced the availability of its CGV-900, a compliant angle grinder. The robotic end-of-arm tool is designed to be used for grinding and finishing processes and eliminate the need for humans to do those tasks manually. An end-of-arm tool is installed onto a robot arm to extend its capabilities. In a video demonstration, the company highlighted the CGV-900 while it was installed on a FANUC CRX collaborative robot. The company noted it is going after the metal fabrication, automotive, and aerospace industries with the new tool. Apex, N.C.-based ATI highlighted that the device can be used to…

Found in Robotics News & Content, with a score of 1.53

…Robotics to exhibit with partners Application partners Applied Automation, ATI industrial Automation, and FerRobotics sought out Kane Robotics to exhibit GRIT cobots in each of their booths at Automate 2023 because GRIT operationalizes their products and services in realistic scenarios, said the company. In the Applied Automation booth, Kane will showcase its GRIT XL, a system designed for polishing large objects such as aerospace parts. This is the first time Kane has exhibited with Applied Automation, but Applied’s six distributors offer the Universal Robots robot arm that is used in Kane’s GRIT solution in 41 of the 50 states. “Customers…

Found in Robotics News & Content, with a score of 0.31

…an inverted UR5e robot performing metal parts deburring using ATI tools and its own proprietary, recycled CO2 surface-cleaning technology. The new Operator Interface from Robot27 allows operators to easily access and run pre-programmed functions without touching the UR teach pendant. Machine operators can execute these tasks with just a few clicks and with no possibility of altering any programming. “Attendees visiting our Automate booth will quickly realize how our ecosystem continues to innovate on our platform,” stated Joe Campbell, senior manager of applications development at Universal Robots. “We’re constantly collaborating with partners on addressing new automation frontiers, with Automate being…

Found in Robotics News & Content, with a score of 0.46

…GRIT ST-X system for sanding, grinding, and finishing, using ATI’s UR+ certified Compliant Reciprocating Tool. Universal Robots to show off UR20 at FABTECH For the first time at a fabrication show in North America, attendees will be able to see the UR20 cobot, which has 20 kg (44 lb.) payload. Universal Robots said it can reach further into machines, tend several machines in the same cycle, and handle 25% heavier parts than other UR cobot models. Despite being the company’s most powerful robot arm, the UR20 is the lightest cobot in its class, weighing only 64 kg (141.1 lb.). “We…

Found in Robotics White Papers & Archives, with a score of 15.43

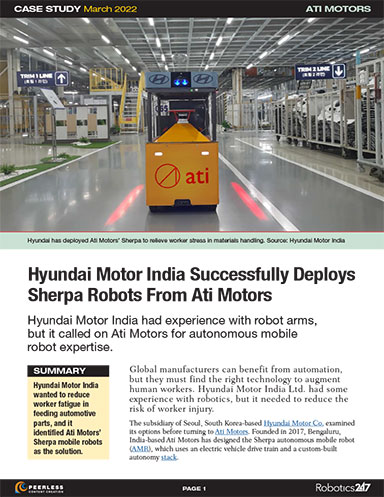

…Motor Co. evaluated a number of options before choosing Ati Motors. Ati Motors' Sherpa autonomous mobile robots (AMRs) stood out because of their ease of use and the Bengaluru, India-based company's strong customer support through a robotics-as-a-service (RaaS) model. The AMRs have an electric drive train and a custom-built autonomy stack. Unlike automated guided vehicles (AGVs), Ati said its AMRs require less infrastructure and allow for more sophisticated fleet management. Not only did Hyundai Motor India's deployment of its first Sherpas reduce dependence on manual operations, but it also led the company to consider adding more robots for different manufacturing…

Found in Robotics Companies & Businesses, with a score of 27.27

Founded in 2017, Ati Motors has an interdisciplinary team of about 30 engineers across machine learning and AI, power electronics, control systems, mechanical engineering, system software, and electronic hardware. The company has developed the Sherpa family of autonomous mobile robots, including Sherpa Tug, which has a payload of up to 1 ton, and Sherpa Light, which is designed for bin movement in electronics assembly plants or e-commerce order fulfillment. Ati Motors has built its technologies—including the electric drive train, vehicle, and autonomy stack—in house. The company added that its systems are industrial Internet of Things (IIoT) and Industry 4.0-ready.

Found in Robotics News & Content, with a score of 3.56

…of robotics startups. Novanta business units Celera Motion and ATI Industrial Automation will collaborate with MassRobotics to advance innovations in medical robotics and improve robot productivity. “As a Boston-based company with technology development and manufacturing in Massachusetts, Novanta is uniquely positioned to be a leader in developing robotics talent for the region,” said Brian Young, chief human resources officer at Novanta. Novanta is a technology partner to manufacturers of medical and advanced industrial systems. The Bedford, Mass.-based company said it has proprietary expertise in photonics, vision, and precision motion technologies. Novanta part of Massachusetts ecosystem MassRobotics is an independent, nonprofit…

Found in Robotics News & Content, with a score of 0.34

…Inspections Lead: Siemens Partners: GelSight Inc., Carnegie Mellon University, ATI Specialty Alloys and Components, Boeing Description: This project will develop a robotic vision and visual tactile inspection system that automates high-resolution surface defect inspections of spacecraft components and commercial airplane fuselages. These technological improvements could improve the quality of aerospace inspections as well as replace manual operations, said the ARM Institute. The inspection system could also improve the reliability, maintainability, and readiness of aviation assets and ultimately to reduce the lifecycle costs of the fleet. AI and robotics would allow the system to standardize and learn inspection processes for many…