Editors’ Picks

Found in Robotics Companies & Businesses, with a score of 17.24

…software to help manufacturers take full advantage of the ease of use, cost-effectiveness, and safety of collaborative robot arms. They include electric, vacuum, and magnetic grippers; the award-winning Gecko gripping technology; and a “2.5D” vision system. OnRobot's product range also includes force/torque sensors, screwdriver and sanding kits, and tool changers. The Danish company said its end-of-arm tooling is supported by the free Learn OnRobot e-learning platform. It is designed to make it easy to deploy collaborative automation for tasks such as such as packaging, quality control, materials handling, machine tending, assembly, and surface finishing, regardless of skill level or previous…

Found in Robotics News & Content, with a score of 7.22

…find a home for them on their shop floors. “Ease of use is not just a ‘nice to have’ feature,” said Joe Campbell, senior manager of applications development and strategic marketing at collaborative robot leader Universal Robots. “It’s key to breaking down the traditional cost and complexity barriers to automation adoption.” Robot designs imitate consumer devices An examination of the ease-of-use features on the market today reveals that many mimic everyday consumer technology. Robotics companies are applying this approach to both hardware and software. To see how designers are using familiar technology to break down the barriers to robot adoption,…

Found in Robotics White Papers & Archives, with a score of 6.17

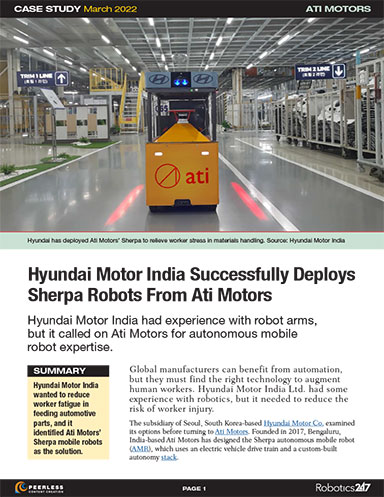

…number of options before choosing Ati Motors. Ati Motors' Sherpa autonomous mobile robots (AMRs) stood out because of their ease of use and the Bengaluru, India-based company's strong customer support through a robotics-as-a-service (RaaS) model. The AMRs have an electric drive train and a custom-built autonomy stack. Unlike automated guided vehicles (AGVs), Ati said its AMRs require less infrastructure and allow for more sophisticated fleet management. Not only did Hyundai Motor India's deployment of its first Sherpas reduce dependence on manual operations, but it also led the company to consider adding more robots for different manufacturing processes. Learn more in…

Found in Robotics White Papers & Archives, with a score of 6.10

“Stepper motors? Servo motors must have better performance.” This is a typical response when asked about stepper motors. Obviously, there is a major misconception about stepper motors. In fact, stepper motors have been used in various types of applications such as advanced equipment and accessible automated instruments. The reasons why stepper motors have been continuously chosen are explained in this article. Some readers may say that they have never seen a stepper motor before. Stepper motors have been used in many applications and industries as the motor solution for drive systems requiring high accuracy control, such as factory automation (FA),…

Found in Robotics White Papers & Archives, with a score of 4.93

For decades, only large manufacturers had the expertise, space, and budgets for automation, but new technologies and business models are making robotics more accessible to small and midsize enterprises. Labor shortages, the reshoring of production, competitive pressures, and government incentives are encouraging smaller businesses to evaluate and adopt robots. They are proving useful for tasks such as materials handling, piece picking, welding, and cleaning. Companies can now scale quickly, thanks to advancements in both hardware and software. And with robotics-as-a-service (RaaS) payment models, customers may not need to make major capital investments upfront. That’s not all. Robotics software is also…

Found in Robotics White Papers & Archives, with a score of 4.67

…cobots, but they share similarities in being designed for ease of use and scalability. Managers looking to build or expand robotics deployments must understand their own processes to determine which are best to automate versus keep manual. In this free download, see what robotics suppliers, software providers, and end users have to say about the technologies, business partnerships, and industry trends shaping collaborative mobile robots. Such systems offer advantages over fixed infrastructure including conveyors, but most facilities are still a long way from “lights-out.” Download this Special Focus Issue to learn more about the following: How mobile robots can mitigate…

Found in Robotics News & Content, with a score of 4.66

…latest capabilities and applications for cobots. We'll also discuss ease of use, assessing tasks and environments for efficiency and safety, and the ecosystem for support. Date: September 22, 2021 Time: 02:00 PM EDT/11:00 AM PDT Tune in to learn: The latest developments in cobots, mobile robots, end effectors, sensors, and the software to guide them What collaborative robotics users need to know for adoption and guaranteeing return on investment (ROI) Use-case examples of how cobots are improving productivity today Register now for this free webcast, and submit questions now or ask them during the live broadcast. Speakers: Lior Elazary, co-founder…

Found in Robotics White Papers & Archives, with a score of 4.59

…more flexible autonomy. We also look at software for ease of use and accelerating robotics adoption, as well as making AI more explainable and accountable. In addition, we examine the ever-evolving software stack for robots and autonomous vehicles and how they connect to manufacturing, warehouse, and enterprise management systems. Here are some topics covered in this free download: Fleet management offerings for mobile robots AI and machine learning for picking systems Improvements in robotic perception and dexterity Efforts around interoperability among robots from multiple vendors Concerns about AI regulations and the robotics industry New tools for developers and end users

Found in Robotics News & Content, with a score of 4.01

…transmit, proccess, and analyze machine data. N-220 designed for ease of use, maintenance The first of a new generation of six-axis articulated robots, the N-220-2.7 or N-220 addresses the market need for cost-effective and easy-to-integrate robots that deliver high-speed industrial performance, said Comau. The robot arm has a 220 kg (485 lb.) payload capacity and features a progressive modular setup, reduced components, and advanced motors, said the company. The holistic design is intended to make the robot easier to install, use, and maintain, Comau said. The N-220 has a wide working area and Performance Level D cartesian safety features, the…

Found in Robotics News & Content, with a score of 3.89

…following considerations for mobile robots: The role of open-source software in developing and using mobile robots How to improve ease of use for workers on the factory or warehouse floor The types of data that managers need for efficiency and throughput The need to coordinate processes, robots, and people Robotics as a service (RaaS) and mobile robot fleets The need for interoperability among systems from multiple vendors and current standards efforts Listen in today!

Found in Robotics News & Content, with a score of 3.89

…following considerations for mobile robots: The role of open-source software in developing and using mobile robots How to improve ease of use for workers on the factory or warehouse floor The types of data that managers need for efficiency and throughput The need to coordinate processes, robots, and people Robotics as a service (RaaS) and mobile robot fleets The need for interoperability among systems from multiple vendors and current standards efforts Listen in today!

Found in Robotics News & Content, with a score of 3.77

…robots met and exceeded those expectations. Proof of the ease of use of our solutions, the pilot robot was operational the very afternoon following its delivery to the site,” said Pascal Rialland, CEO of BALYO, in a statement. “The deployment of a fleet of 10 robots within this site is planned over H2 2023,” he said. “This new deployment is an example of the many advances made by BALYO in recent years, both in terms of performance and ease of use of our robots.” “The robotization of logistics flows remains at the heart of the challenges facing manufacturers and BALYO…