Editors’ Picks

Found in Robotics News & Content, with a score of 14.89

…include Aristotle University of Thessaloniki (Greece), the Danish Technological Institute, Fraunhofer IFF (Germany), University of York, (United Kingdom), University of Antwerp (Belgium), Norwegian University of Science and Technology (Norway), PAL Robotics (Spain), ISDI Accelerator (Spain), and Simula Research Lab (Norway). Industrial use case studies already underway RoboSAPIENS sait it will build on a current autonomic computing framework known as Monitor-Analyze-Plan-Execute-Knowledge (MAPE-K) to include adaptive controllers in robotic applications, and reconcile it with stringent safety requirements. Generation of the adapted controller settings will largely rely on deep learning and digital twin simulation techniques. Automated virtual and real tests will be deployed…

Found in Robotics News & Content, with a score of 41.43

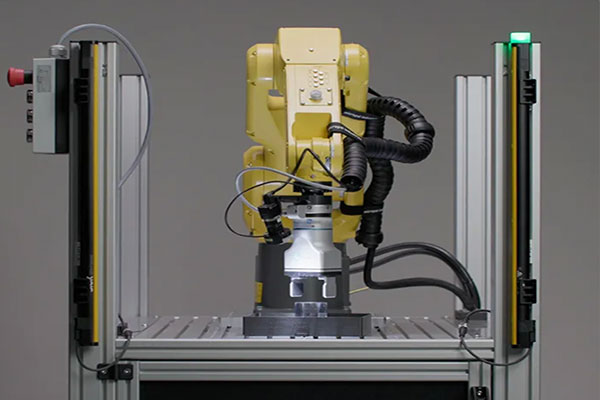

…provider Micropsi Industries recently announced a partnership with the Fraunhofer Institute for Factory Operation and Automation (IFF) to open a new use-case research laboratory in Magdeburg, Germany. Additionally, Micropsi will demonstrate applications of its AI-based MIRAI machine vision system, including reflective disc picking and hook hanging, at ATX West in Anaheim, CA February 6-9 at booth 4566. Micropsi said U.S. companies can work with a local team during and after the show to workshop use cases for the new lab. Robot arms to demonstrate MIRAI variance adaptation Micropsi said applications such as reflective disk picking and hook hanging are too…

Found in Robotics News & Content, with a score of 15.49

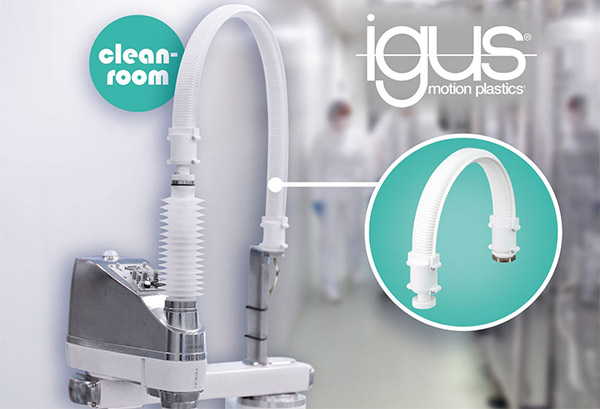

…to tribologically optimized high-performance plastic. Its ISO certification by Fraunhofer Institute experts confirms this. The Clean SCARA Cable Solution has ISO Class 2, meaning that it is so abrasion-resistant that a maximum of 100 particles up to a size of 0.1 microns can be found in one cubic meter of air during operation. For comparison, a sheet of paper is 80 microns thick, or 800 times as thick as a particle. Clean SCARA Cable Solution as an alternative to classic corrugated hoses With its new energy supply system, igus offers an alternative to classic corrugated hoses, which has two other…

Found in Robotics News & Content, with a score of 16.62

…because of tribologically optimized high-performance plastic, said igus. The Fraunhofer Institute has confirmed this characteristic for an ISO (International Organization for Standardization) certification for cleanrooms. The Clean SCARA Cable Solution has ISO Class 2, meaning that it is so abrasion-resistant that a maximum of 100 particles up to a size of 0.1 microns can be found in one cubic meter of air during operation. For comparison, a sheet of paper is 80 microns thick, or 800 times as thick as a particle. igus said its new power system is suitable for electronics cleanrooms. Source: igus igus presents Clean SCARA Cable…

Found in Robotics News & Content, with a score of 19.72

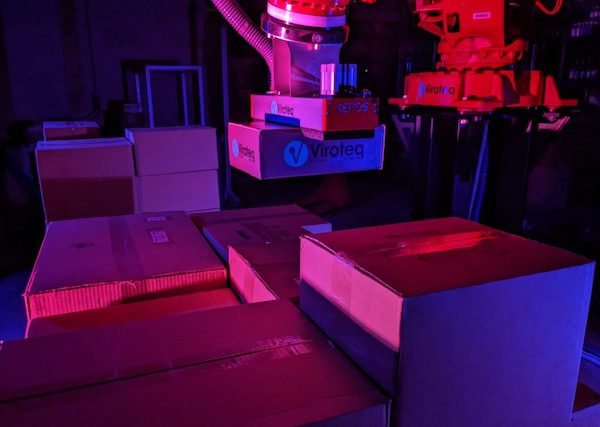

…Source: Viroteq Viroteq victorious at ICRA Vanderlande and the Fraunhofer Institute organized the virtual challenge to raise awareness of parcel-stacking and loading systems in sectors that struggle with labor shortages. Vanderlande provides logistics systems for the airport, parcel, and warehousing segments. Manual stacking and loading processes are physically strenuous, noted the companies. With the increase in parcel varieties and requirements for process flexibility, the industry is demanding automation, but the technical complexity is high, they said. Thirty-nine contestants from around the world participated in the virtual stacking challenge at ICRA 2023. Viroteq said it used the StackrBrain AI technology to…

Found in Robotics News & Content, with a score of 17.20

…expand with this investment.” Meyer, who worked at the Fraunhofer Institute for Production Engineering and Automation at the time, founded Commonplace Robotics in 2011. The Bissendorf, Germany-based company said it works to make the integration and operation of robots so cost-effective and easy that they can be used anywhere. Its first products with a control system and proprietary power electronics were robots for teaching. Commonplace Robotics cooperates for affordable robots The two companies said they have been cooperating intensively since 2016. Commonplace Robotics and igus have jointly developed products including an actuator, the ReBeL low-cost collaborative robot, and the igus…

Found in Robotics News & Content, with a score of 77.54

…robots in a variety of environments. Researchers at the Fraunhofer Institute for Material Flow and Logistics, or Fraunhofer IML, are using NVIDIA Omniverse for applied research in logistics for fulfillment and manufacturing. They are also using NVIDIA Isaac Sim for simulation in robot design. Fraunhofer IML's goal is to ease the transition from automated guided vehicles (AGVs) to faster-moving autonomous mobile robots (AMRs). This advancement in automation promises to significantly accelerate logistics, said the Dortmund, Germany-based institute. “We’re heading the research aspects for AMRs, and we’re looking at how we can go as fast and as safely as possible in…

Found in Robotics News & Content, with a score of 21.20

…A1, GO1, and ANYmal quadrupeds, as well as the Fraunhofer Institute's O3dyn (formerly “Obelix”) indoor/outdoor pallet-moving system. “Fraunhofer's AMR [autonomous mobile robot] is omnidirectional, can move fast, and can pick up heavy loads,” said Andrews. “It has plans to open-source the platform.” “Our panel on digital twins at Automate last week was well-received,” he recalled. “The panelists from companies like Kroger and our newly announced partnership with READY Robotics demonstrate that the technology is becoming really important to diverse users.” “Our discussions with them and people at our booth showed that it's not just the technology providers—end users are starting…

Found in Robotics News & Content, with a score of 32.71

…reasons why organizations are seeking automated solutions,” Mühlens said. Fraunhofer Institute designs dual-arm cucumber harvester Harvesting cucumbers is a physically demanding task. Some companies have workers lie prone on a support surface behind a vehicle, picking the vegetables off the vines by hand. In more rudimentary businesses, workers walk down rows carrying a harvesting bucket, bending down to look for the ripe cucumbers. Carrying boxes that weigh up to 12.2 kg (27 lb.), the workers must walk, bend, stoop, and reach. Finding workers to perform these tasks has become increasingly difficult. In response to this challenge, the Fraunhofer Institute for…

Found in Robotics News & Content, with a score of 14.94

…AG, a global systems integrator, as well as the Institute for Materials and Logistics to design and build the 600,000+ sq. ft. distribution center in Espelkamp, Germany. The facility, which went live in September 2019, is a showcase for warehouse and distribution center automation. It features technologies including the following: Automatic guided vehicles (AGVs) for non-value-added travel Automatic depalletizing, palletizing, and shrink-wrapping Pallet- and carton-handling, crane-based automated storage and retrieval systems (ASRS) Vertical lift modules (VLM) for small parts storage A shuttle system for buffer storage of order totes Pallet conveyor with transfer cars RFID for pallet tracking and quality…

Found in Robotics News & Content, with a score of 50.88

…Industries news, the company launched a new partnership with Fraunhofer Project Center at the University of Twente and the Fraunhofer Institute for Production Technology IPT in Aachen, Germany. Ampower, an additive manufacturing consultancy, concluded in their independent benchmark study “Productivity Evaluation for Metal Additive Manufacturing Systems” that Additive Industries’ MetalFAB1 systems combine the lowest system investment with the lowest total cost per part and highest annual capacity. They tested four typical parts from various industries like medical hip implants, impellors from oil and gas industries, and parts from the automotive and aerospace industry. In all cases the MetalFAB1 won over…

Found in Robotics News & Content, with a score of 40.96

…positive interim result of the Bionic Aircraft project: The Fraunhofer Institute for Additive Production Technologies IAPT, has developed optimized support structures. Support structures provide the needed support to additive manufactured components at certain areas, for example at overhangs, and must be removed after the 3D print. “Thanks to an optimized geometry, the new support structures do not need as much powder. We were inspired by nature, which is known for its material efficiency. The hierarchically branched structures with gradients that were created as a result reduce powder consumption by 70 to 90 percent as compared to conventional support structures. This…