Last month, the Yara Birkeland completed its maiden voyage to Oslo and then sailed on to Posgrunn, the southern Norwegian production site of Yara International, a fertilizer manufacturer and owner of the vessel. The company claimed that it is the first fully electric and autonomous container ship.

“Yara is constantly seeking opportunities to reduce its climate footprint and fulfil its main vision to responsibly feed the world,” stated Jon Sletten, project owner, Yara Birkeland. “Embarking on a technically challenging project as Yara Birkeland together with our technology partner Kongsberg Maritime is ... a small endeavour in the large challenge we, as one out of many industrial players, are embarking on.”

“A zero-emission vessel to bring our product from production and out to the markets shows that it is possible to make a positive contribution to the required change in the release of climate gases,” he added. “Battery technology from Leclanché provides us with a battery-driven vessel charged with electricity from the green hydroelectric power. This is a willful step in a green direction and an encouragement for others to also invest in future technologies.”

Leclanché provides batteries for Yara Birkeland

The Yara Birkeland will soon commence commercial operations while beginning a two-year test period, prior to entering fully autonomous operation on a route off the coast of Norway.

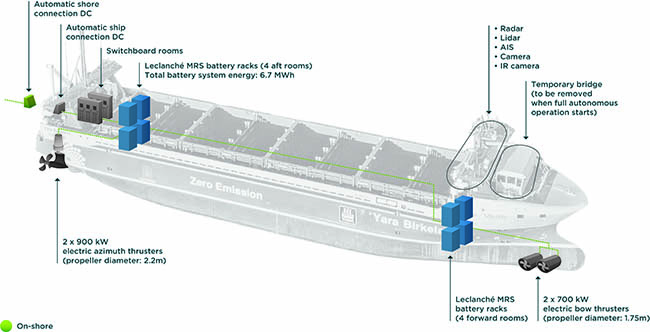

The container ship is about 80 m (262.4 ft.) long and 15 m (49.2 ft.) wide, with a deadweight of 3,120 tonnes (6.8 million lb.) or 120 standard containers (TEU). This electrically powered “green vessel” will operate at a service speed of approximately 6 knots, with a maximum speed of 13 knots. It is fully powered by a high-energy lithium-ion battery system from Leclanché SA in Yverdon-les-Bains, Switzerland.

Leclanché said its technology is based on more than 100 years of battery and energy storage innovation. The company claimed that its culture of German engineering with Swiss precision and quality make it a trusted partner for companies and governments interested in the disruption of the energy distribution network and next-generation transportation.

In addition, Leclanché said it is one of the few European battery suppliers that has its own cell production facilities and the complete know-how to produce high-quality lithium-ion cells—from electrochemistry to battery management software and an array of battery systems. The company has business units organized around stationary storage systems, specialty batteries, and electrified transports.

It noted that its e-Marine business segment is its fastest-growing one. Leclanché has completed projects such as Ellen, a passenger and vehicle ferry that has been operating in the Danish Baltic Sea since 2019 and that it said is the longest-range, all-electric ferry in daily operation.

Leclanché supplied the Yara Birkeland with a 6.7 MWh battery system, which represents the same energy as 130 Tesla Model 3 batteries. It includes integrated liquid cooling to ensure optimum operating temperature, said the company. The company added that its Marine Rack System (MRS) guarantees reliable operation over a service life of at least 10 years.

“Leclanché's Marine Rack System provides 30% higher energy density and up to a 230% greater life cycle than competitive systems – in addition to its reputation for having the safest battery system design,” said Guillaume Clement, vice president of e-Marine at Leclanché. “Thanks to Yara, the maritime industry has entered a new era where sustainable shipping is demonstrated as a viable solution for a very large range of ships and businesses.”

Reliability and safety features

The Yara Birkeland's battery system includes lithium-ion cells produced at Leclanché's automated production facility in Willstätt, Germany, and battery modules made in Switzerland. The high-energy density cells have a long life cycle of 8,000 at 80% depth of discharge (DoD), with operating temperature ranges from -20 to +55°C (-4 to +131°F), said Leclanché.

The MRS consists of 20 strings with 51 modules of 32 cells each, for a total of 32,640 cells. The battery system has built-in redundancy, with eight separate battery rooms. If multiple strings are emptied or stop working, the vessel can continue its operations.

In addition, the MRS offers protection against overheating and an integrated fire-protection system specifically designed and certified for maritime requirements.

To prevent a fire on the open sea, Leclanché developed the modular DNV-certified MRS. Each battery string contains gas and smoke detectors, redundant thermal monitoring and a cooling system to prevent overheating and thermal incidents.

Should a thermal incident occur despite all of the precautions, the Fifi4Marine fire-extinguishing system would kick in, said Leclanché. It is based on environmentally friendly foam and is intended to cool and extinguish quickly and effectively.

Setting sail for sustainability

Once the test period is completed, the Yara Birkeland will navigate on a completely autonomous basis, transporting containers products from Yara International's production plant in Herøya to the port of Brevik.

Yara International said it is pursuing a zero-emission sustainability strategy with the all-electric drive. It will also reduce noise and air pollution while in port.

“We are very proud to be able to contribute to the success of this unique project,” said Anil Srivastava, CEO of Leclanché. “With our battery system for the Yara Birkeland, Leclanche contributes to lower greenhouse gas emissions equivalent to 40,000 [diesel] container truck road journeys per year, not to mention road safety improvements, noise pollution reduction, and increased logistics efficiencies.”

“The annual operating cost savings in both fuel and crew, estimated at up to 90%, makes autonomous and battery-powered ships viable in international trade,” he said. “Combined with new emerging technologies and the integration of alternative green fuels, including clean hydrogen, we will continue opening new possibilities for our customers, the industry and the planet.”

Article topics

Email Sign Up