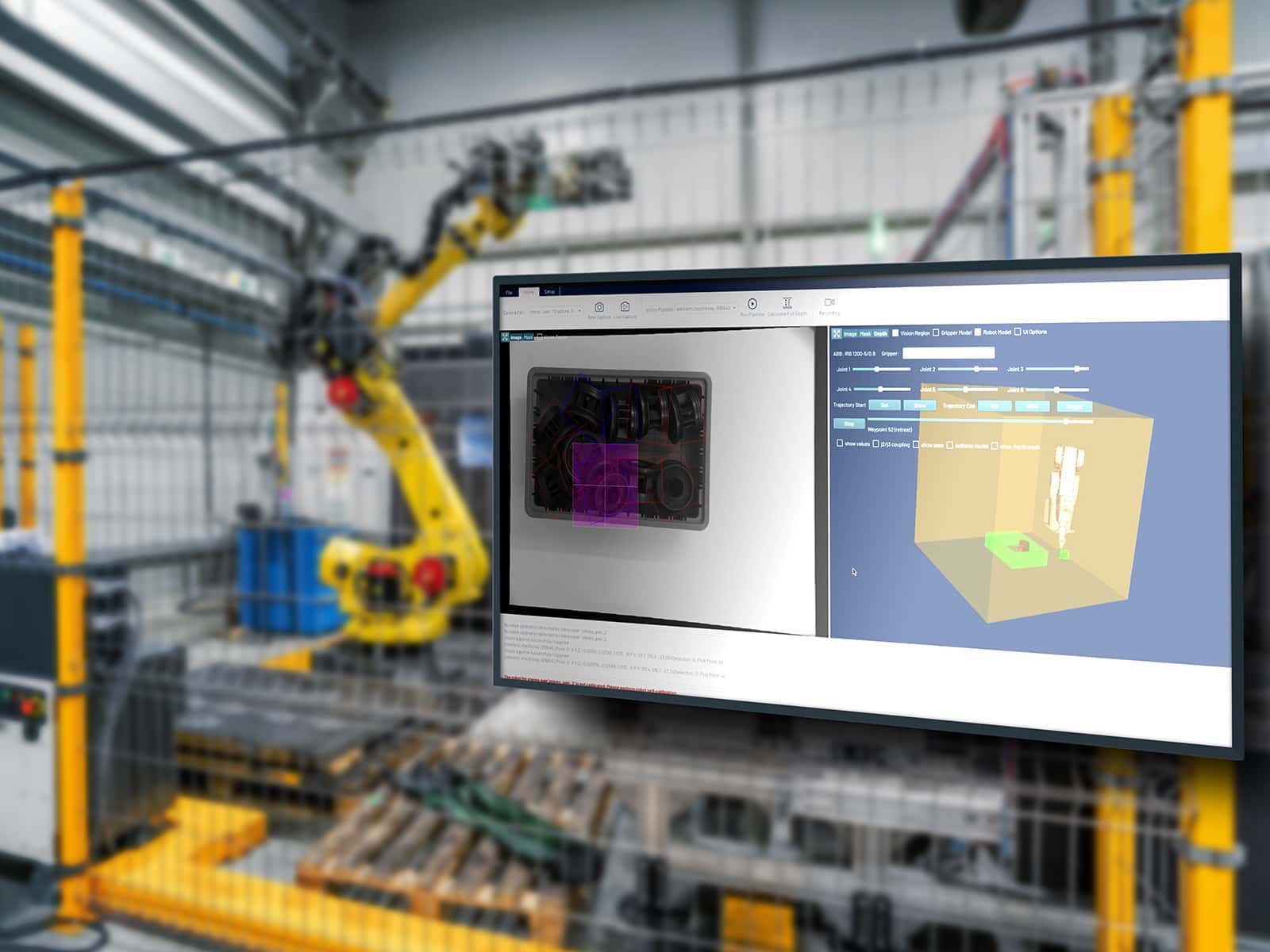

The latest release of the Vue, 4D vision software for robotic automation, features a host of new capabilities that allow for more granular control and optimization to further its ability to identify objects and ensure cell success.

While Vue has always exceled at vision programming tasks, the latest release now adds more control over the implementation of vision. Vue builds in more control over choosing pick points, approach angles in and out of robot moves, and avoiding interference with adjacent objects in Dexterity, Apera’s two-finger gripping intelligence.

Using these innovations, engineering teams can implement or improve vision-guided robotics more easily and without specific vision expertise. Engineers working in Vue can improve the productivity and reliability of the robots in a cell using built-in software tools.

Autopilot is Apera Vue software’s feature that enables safe paths in and out of moves. Autopilot identifies the object, guides the robot’s movement, and helps it avoid singularities or collisions. Before an engineer tells the robot to move, Autopilot can now simulate the automation within the real, fully-built cell. Ahead of an automation investment, this means knowing the robot, gripper, and cell design will perform the way expected. Once installed, it provides extra assurance that the task can be performed quickly and reliably, even when new tasks enter the picture.

Other features allows Vue users to upload a CAD model of custom grippers or end of arm tools and achieve superior gripper to part orientation. Customers report that custom end-of-arm tooling (EOAT) can be a challenge to the performance of a vision-guided cell. In Vue, you can upload a CAD model of the EOAT and achieve excellent EOAT to object orientation. That matters a lot in assembly or material handling applications where a part must be precisely placed for the next step of manufacturing.

Apera’s Tier 1 automotive customers report significant advantages with this feature, including the ability to pair robots together more reliably, which helps lower the risk of custom EOATs.

Watch this video to learn more about how AI-powered vision is changing robotic guidance and inspection.

Article topics

Email Sign Up