Intelligent design and intuitive WMS simplify complex processes

viastore has implemented an efficient Warehouse Management System (WMS), with an automated warehousing and picking solution for German medical technology product manufacturer Bort.

After scrutinizing Bort’s material flow, viastore installed an intuitive system that manages the complex processes quickly and reliably – from goods receiving, through kitting to order picking and shipping.

Bort Medical is a success story. It all began back in 1981 when husband and wife, Rudi and Irmgard Bort, founded a trading company for medical products in Schorndorf (near Stuttgart). Initially employing three part-time workers in rented premises, the company founders soon decided to set up their own production in addition to selling products from third-party manufacturers.

Since then the company has grown continuously, earning itself a reputation for developing, and manufacturing high-quality medical products, in particular supports and braces.

At the company’s current headquarters in Weinstadt, not far from Schorndorf, the family-run company today employs around 90 people, including 25 field service staff. At two more locations in Germany, a further 200 employees manufacture about 90 percent of the 5,000 high-quality medical support and brace device items that Bort sells. Bort delivers its products to medical supply stores, specialist medical retailers, hospitals and pharmacies.

The maximum pick performance achieved to date is 18,000 items a day. From left: Purchasing and Logistics Manager Peter Röbbig (Bort), Managing Director Wolfgang Bort and Wolfgang König, Project Manager at viastore.

Medical products must be immediately available, so logistics has always played a crucial role at Bort. As many as 15 years ago, the company took the first step towards automating its intralogistics processes, replacing order picking right off the shelf by order slips.

But as the company continued to grow, this system soon reached its limits. “We do everything we can to supply our customers immediately and complete all the orders on the same day we receive them,” says Managing Director Wolfgang Bort. That was no longer possible with the old solution in such a confined space. He decided to build a new distribution, administration and development center with 25,000 square-meter (270,000 sq. ft.) floor space in the immediate neighborhood.

New System Enables Further Growth

A new facility offered the company the opportunity to plan a new, scalable automated intralogistics system from scratch. The objectives were clearly defined: The system should allow a doubling of throughput in the first expansion stage, and a tripling in the final stage.

Speed should go hand in hand with a high level of reliability and minimal error rates. Bort also attached great importance to good service from the system partner. Time and time again, the company had had trouble with the provider of the former solution. “Technical problems were solved only with difficulty. What’s more, long distances cost us much time and caused a considerable amount of trouble,” says Wolfgang Bort.

In his search for a suitable project partner, Peter Röbbig, Head of Purchasing and Logistics at Bort, quickly came across viastore. The staff of the intralogistics specialists impressed him with their industry experience and their expertise gained from working for a full-range supplier of intralogistics systems and intralogistics software - from consulting and system planning through to plant engineering and complete system support. “It was very important for us to get everything from a single source and to have one company to contact for all questions,” says Wolfgang Bort.

Clearly Structured Material Flow

viastore implemented a turnkey automated distribution center that consisted of a 10 meter (33 ft) high bulk storage area with approximately 12,000 rack container locations with double deep storage and two viaspeed mini-load automated storage & retrieval machines (AS/RS). A 6.4-meter (21 ft) order picking section with about 11,000 rack locations and four additional viaspeed AS/RS, as well as an extensive conveyor system comprised the complete system.

In the picking area, 1,442 pick channels with pick-by-light displays and ergonomic high-performance pick stations are available for order picking in eight zones. A high-speed conveyor loop ensures quick connections between warehouse, picking and packing areas.

For viastore Project Manager Wolfgang König, the challenge was to take a complex picking process and make it simple for Bort employees. “We had to simplify the high complexity of processes for the Bort employees so that they would be able to work intuitively at the various stations,” he says. After all, Bort’s range of products, including all the various sizes and designs, comprises some different 5,000 SKUs altogether. And these need to be delivered to customers as quickly as possible and in the correct combination.

viastore implemented a clear material flow structure at Bort and created an ergonomic system with easy-to-use software. Bort receives goods from various production sites in cartons of different sizes. Following quality inspection these are repacked into lidded black storage containers and transported to the bulk storage AS/RS area. This serves to store those goods that are not yet ready for sale - meaning goods that are not yet packaged into individual boxes with instructions for use and the correct label.

WMS Also Manages The Kitting Process

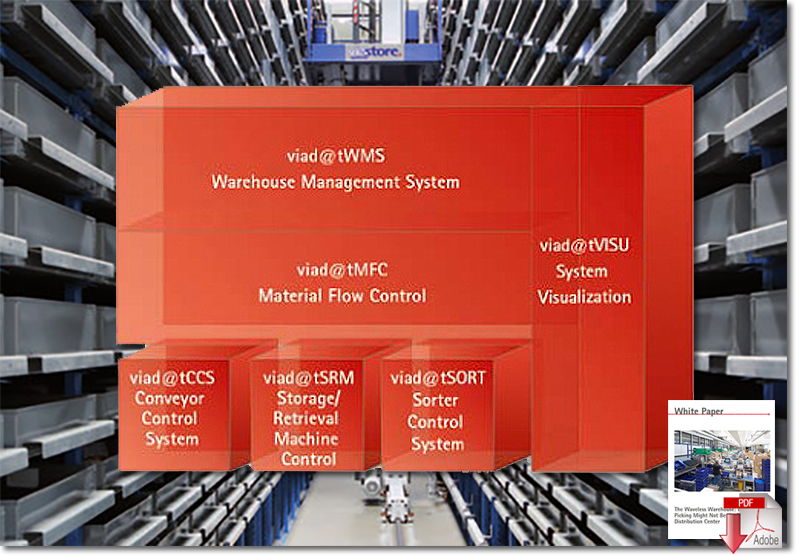

Connected to Bort’s ERP Navision, the viad@t warehouse management system (WMS) monitors and controls the inventories in the order picking section depending on demand. If stock drops below a certain level for a specific product, the WMS triggers a kitting process: Products, instructions and boxes are retrieved from the bulk storage area and delivered to one of ten pack stations where employees put together the items ready for shipping. The items are placed into blue containers which distinguishes them from goods not yet ready.

Order picking is performed according to two principles: The pick channels are automatically supplied by the viastore AS/RS. The pick operation – in this case A-parts – is self-explanatory for the employees: the WMS calculates the order volume and automatically determines what size container for the operator to place the goods into. Upon entering the picking areas, the containers are scanned automatically, which triggers the order picking. Lights on the pick channels clearly indicate which channel and what quantity to pick from. When picking is completed, the container is simply pushed away. It is then transported to the next picking area or to the packaging and shipping station.

Ergonomic Order Picking Increases the Quality of Delivery

In front of the order picking section there is a pick station where Bort employees pick the slower moving B and C parts. The containers for these goods are retrieved automatically and depart again after retrieval without the employee having to initiate this process. A WMS dialog on the screen clearly shows the order pickers how many items they should pick from each container segment as the containers are divided into several compartments for smaller products.

The WMS also shows what target container the items should be placed into via light indicators. In the pick container a “spot” appears in the right place, and the number of items is illuminated above the target container. If an employee is about to put items into the wrong target container by mistake, this will trigger a visual and audible alarm. Additionally, the weight is controlled directly at the target locations. If this differs from the target weight, a message appears.

Bort CEO Wolfgang Bort attaches the highest value to delivery quality: “Customer complaints are toxic for our business, so the pick process is designed to minimize the chance of errors.” In addition, viastore installed high-precision scales with tolerances of +/-5 grams at further relevant positions in the conveyor system. If the actual weight of a container deviates significantly from the target value, the container is sent to QA for investigation. “This gives us additional security. We place great emphasis on ensuring that the orders are correct when shipped,” Logistics Manager Peter Röbbig points out.

Professional Collaboration

The viastore solution is the foundation for further growth at Bort. “Picking should be much faster and more reliable from now on,” added Wolfgang Bort, who will cut the error rate down to the one in a thousand range with his new intralogistics solution. “Our goal is to bring this rate down to such a degree that our final inspection is no longer needed.”

Bort describes collaboration with the viastore staff as “highly professional”. And as Peter Röbbig says: “We were familiar with the system after only a relatively brief training period.”

Even during the initial phase, the warehouse staff processed between 1,600 and 1,700 orders per day with the new system. So far, the recordpicking performance was 18,000 items in one day. Furthermore, the viastore system is running at 70 percent capacity and so the next extension stage is already planned.

Related: AS/RS the ‘Backbone’ of an Automated Material Handling Logistics Solution

Article topics

Email Sign Up