Last week, Velo3D Inc. announced the delivery of its first Sapphire XC metal 3D printer to an aerospace customer. The additive manufacturing system is designed for faster production and larger, mission-critical parts, according to Velo3D.

“I believe that the Sapphire XC will quickly become the gold standard in advanced metal additive manufacturing,” stated Benny Buller, founder and CEO of Velo3D. “Because our customer is already utilizing our end-to-end production solution, they can immediately and seamlessly move parts to Sapphire XC to achieve a phenomenal production rate increase.”

“We made a huge effort to ensure that Sapphire XC uses the exact same manufacturing process as Sapphire,” he added. “The ability to move production seamlessly between different products was considered impossible when we started Velo3D, but I am proud to declare that we have unlocked this ability for our customers and partners. It is a huge accomplishment—our biggest achievement of 2021.”

Since its invention almost 30 years ago, additive manufacturing (AM) has improved how high-value metal parts are built, but it has limited capabilities, said Velo3D. The Campbell, Calif.-based company said its system allows for more design freedom and enables customers in the aerospace, energy, and semiconductor industries to create parts that were previously impossible to manufacture.

Sapphire XC uses existing software

Velo3D delivered its first Sapphire system in 2018. The Sapphire XC, for “extra capacity,” is a scaled-up version of the Sapphire Printer. It uses the same Flow print-preparation software, the same Assure quality-control software, and the same Intelligent Fusion manufacturing process as its predecessor.

Flow analyzes part designs and prescribes a set of known recipes needed to manufacture the part, said the company. Customers can simply upload the CAD file for a part they would like to print, and the software’s integrated simulation engine creates a file that can be used across any device to build exactly the same part.

As parts are printed, Assure monitors the build and provides detailed reporting for full traceability, layer by layer. This gives customers confidence that the parts produced are identical across Sapphire printers, said Velo3D.

Velo3D works to reduce production costs

Sapphire XC is intended to enable a seamless transition of parts that were developed and qualified on Sapphire to the larger Sapphire XC, reducing the cost of production by up to 75%, the company claimed. It also cited the following features:

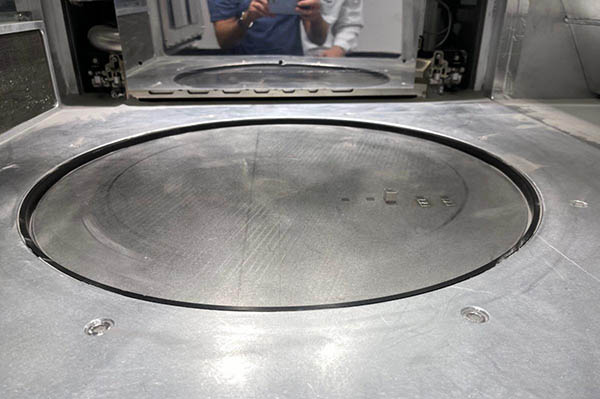

- Larger build volume: The Sapphire XC is one of the largest available laser powder bed fusion (LPBF) printers, with a build volume of 600 mm (23.6 in.) in diameter and 550 mm (21.6 in.) in height—400% larger volume than the original Sapphire system.

- Additional lasers: The Sapphire XC uses eight 1-kilowatt lasers to selectively weld powdered metal layer by layer. Velo3D’s Sapphire system uses two 1-kilowatt lasers.

- Faster non-contact recoater: Compared with the original Sapphire, Velo3D’s proprietary, protrusion-tolerant recoater is now twice as fast on Sapphire XC, significantly reducing non-productive overhead time.

The Sapphire XC is able to print using a wide variety of materials in the production of mission-critical parts in the aviation, aerospace, defense, oil and gas, and energy industries. The list of available metals includes Inconel 718 & 625, Hastelloy X, Hastelloy C22, Aluminum, Scalmalloy, and Titanium Ti-6Al-4V. Velo3D said it continually evaluates and qualifies new materials for use in its end-to-end solution.

Aerospace customer scales up AM

The aerospace company receiving the new Sapphire XC said it plans to scale up production of items already produced by its existing fleet of Sapphire metal 3d printers.

The ability to seamlessly transition from the Sapphire to the Sapphire XC is a key differentiator for the company, said Velo3D. This is made possible by its end-to-end solution that preserves design intent and delivers predictable, repeatable outcomes, it said.

Velo3D currently has a backlog of firm bookings for 17 additional Sapphire XC systems as well as 19 additional reservations. The new printer's ability to reduce production costs and create much larger parts is driving this demand, said the company.

Velo3D has been a strategic partner to innovators such as SpaceX, Honeywell, Honda, Chromalloy, and Lam Research. It was also named to Fast Company’s annual list of the World’s Most Innovative Companies for 2021. In March, Velo3D announced plans to merge with JAWS Spitfire Acquisition Corp. and be publicly traded.

Article topics

Email Sign Up