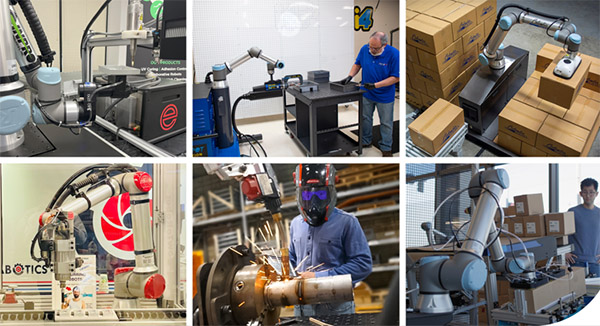

Universal Robots A/S claimed that not only are its collaborative robot arms the most widely used cobots in the manufacturing industry, but they have also become the platform of choice in the fast-growing OEM ecosystem. The company said this will be demonstrated at Automate 2023, where more than 60 UR cobots will be exhibited in over 30 booths.

In addition, Roberta Nelson Shea, global technical compliance officer at Universal Robots, will be recognized with the Engelberger Robotics Award, which the company called the “Nobel Prize of Robotics.”

Founded in 2005, Universal Robotics is a leading provider of collaborative robots for education and a wide range of industries. The Odense, Denmark-based company said it introduced the first commercially viable cobot in 2008.

Since then, it has developed a portfolio with a range of reaches and payloads and sold more than 50,000 cobots worldwide. Univeral Robots said it has also developed an ecosystem including a wide range of components, kits, and systems for numerous applications.

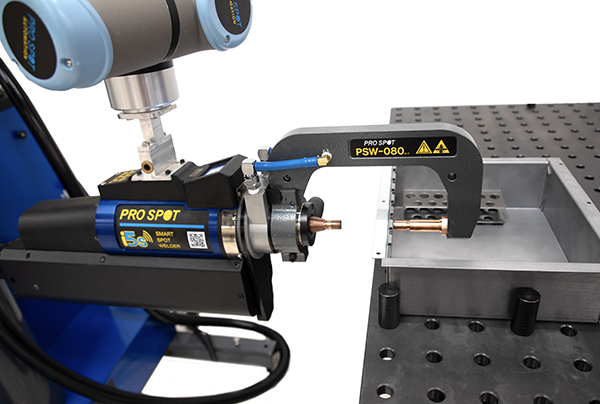

'First cobot spot welder' on display

At Booth 3623 at Automate, which will be in Detroit from May 22 to 25, Universal Robots plans to showcase the latest innovations, including what it said is the “world’s first cobot spot welder.” The system was designed and manufactured by Pro Spot International Inc.

While other welding technologies such as MIG welding have become popular choices for collaborative robots, spot welding has been prohibitive for cobots until now because of the weight of the weld gun and the complexity of the welds, noted Universal Robots. With the new i5s resistance spot welder, Pro Spot has developed a lightweight system that delivers two to three times more manufacturing capacity than manual spot welding, it said.

“We married our most sophisticated spot welder with Universal Robots’ safe, unrivaled technology,” says Ron Olsson, president and founder of Pro Spot. “The combined platform is a powerhouse of productivity and throughput greatly benefiting any manufacturer who joins sheet metal through spot welding.”

Another manual welding tool now incorporated in a cobot application is the new rotational positioner from THG Automation, addressing any welder who ever struggled to weld circular or odd-shaped parts.

“Welders use positioners manually all the time, and it was a natural progression for us to incorporate positioners into our collaborative welding system to allow the weldments to be presented to the robot at a more optimal orientation,” said Matt Hendey, CEO of THG Automation, who will be showing the positioner incorporated in his company’s Fronius Perfect Welding CMT system using a UR10e cobot.

Both welding partners—along with many other UR integrators, OEM partners, distributors, and customers—plan to incorporate the new UR20 cobot into their applications for added reach and payload capabilities. The award-winning UR20, with a 20 kg (44 lb.) payload and 1,750 mm (68.8 in.) reach starts shipping later this summer.

Universal Robots will show the UR20 at its booth in a machine tending application, loading and unloading heavy workpieces into a machine fixture.

New takes on palletizing, case packing

Manufacturers looking to verify whether a UR cobot palletizer will work for their applications can now receive a complete project analysis with performance and installation data delivered right in UR’s booth.

With MyRobot.cloud, Rocketfarm is launching the first digital twin designed for palletizing with UR cobots. Integrators can now quickly verify customer projects on site. The system will be demonstrated with partner Columbia/Okura’s miniPAL, a mobile palletizing solution powered by the UR10e cobot arm.

The flexible miniPAL, with a total workspace footprint of 11 x 13 in., can palletize at two pallet locations for optimized productivity. The latest design includes three area safety scanners that can detect human presence in the palletizing work envelope, said the companies.

This ensures safe, “collaborative mode” operation in the presence of workers while allowing the miniPAL to operate at maximum rates when people are not within the work zone, they said. A “big brother,” the miniPAL+ featuring a UR20 cobot, will be available for preorders in the booth.

Driven by a shared vision of helping manufacturers deploy cobots at scale, Rapid Robotics’ strategic partnership with Universal Robots has supported its expanded offerings to include vital end-of-line applications such as box-building, packing, and palletizing.

At the UR booth, Rapid will exhibit a case-packing operation using a UR5e that is integrated with its software stack. Attendees can see the pretrained cobot pick up multiple bottles at once and then pack them neatly into a case, an operation that Rapid has implemented for a major distributor of funeral home supplies.

Partners to show multi-tasking cobots

INPRO Technologies’ fully integrated gasketing station for instantaneous curing with plasma treating, liquid gasket dispensing, and UV light will deonstrate the ability of UR cobots to handle entire process cycles, said Universal Robots. The station will features a robot arm performing assembly/disassembly, material handling, and process-control tasks, all while serving as the main programmable logic controller (PLC).

RoboRoom from Reliabotics is a new UR-based 48 x 50 in. modular turnkey automation workcell. It is designed to automate applications such as surface deburring and finishing, assembly and testing, picking and placing, dispensing and bonding, and visual inspection.

At Automate, RoboRoom plans to show an inverted UR5e robot performing metal parts deburring using ATI tools and its own proprietary, recycled CO2 surface-cleaning technology.

The new Operator Interface from Robot27 allows operators to easily access and run pre-programmed functions without touching the UR teach pendant. Machine operators can execute these tasks with just a few clicks and with no possibility of altering any programming.

“Attendees visiting our Automate booth will quickly realize how our ecosystem continues to innovate on our platform,” stated Joe Campbell, senior manager of applications development at Universal Robots. “We’re constantly collaborating with partners on addressing new automation frontiers, with Automate being the perfect discovery pad for our rapidly expanding solution portfolio.”

Nelson Shea to receive Engelberger Award

Universal Robots noted that its expanding ecosystem is enabled by the open platform design originally developed by the company’s co-founder and then Chief Technology Officer Esben Østergaard. He received the Engelberger Robotics Award in 2018 for his pioneering role in the cobot industry.

Roberta Nelson Shea, Universal Robots' global technical compliance officer since 2016, will join Østergaard. For over 45 years, she has been one of the central figures in the development of industrial robot safety standards in North America and around the world.

As the convenor of the ISO committee, Nelson Shea led the introduction of ISO/TS 15066, which is the first document that defined standardized safety requirements within human-robot collaboration. At Automate 2023, she will receive the prestigious award for her work over the course of her career in global robotics safety.

Editor's note: For more about Automate 2023, visit Robotics 24/7's special coverage page.

Article topics

Email Sign Up