While they may not be as fast or precise as industrial automation, collaborative robot arms are becoming more capable. Universal Robots A/S today announced that it is adding a cobot with a 20-kg payload capacity to its product line. The company said that its first new robot in several years is an all-new design.

“This is not just a bigger version of our existing cobots; it’s the cobot redefined,” stated Kim Povlsen, president of Universal Robots. “The UR20 is the most innovative cobot we have produced and the latest evolution in 17 years of technical experience in the robotics industry.”

“Our expert engineers have completely re-engineered the arm while retaining the same intuitive user interface we have long been celebrated for,” he added. “The benefits of the UR20 are significant, from faster cycle times and the ability to handle heavier loads, to greater reach with a small footprint. We’ve also incorporated advanced software enhancements, giving users unprecedented motion-control capabilities.”

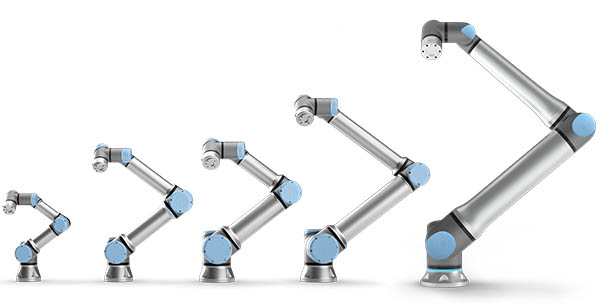

Universal Robots said it launched the world’s first commercially viable collaborative robot in 2008. The Odense, Denmark-based company has sold more than 50,000 cobots and reported 41% growth in 2021. Its portfolio now includes the UR3e, UR5e, UR10e, and UR16e robot arms with a range of reaches and payloads.

Each model is supported by a wide selection of end effectors, software, accessories, and application kits in the UR+ ecosystem. This allows the power- and force-limited robots to be used across a wide range of industries and means that they can be redeployed across diverse tasks, said Universal Robots. The Teradyne Inc. unit has built an ecosystem of more than 1,100 integrators, distributors, and independent partners.

UR20 provides more power in tight space

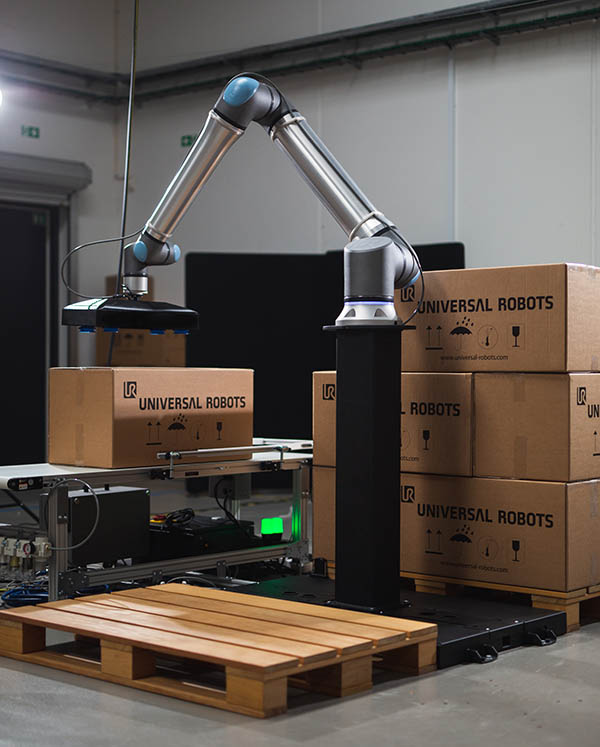

“The UR20 is designed to provide 30% more torque, 20 kg [44.1 lb.] payload, and with a 1,750 mm [68.9 in.] reach. It can handle applications such as standard European pallets of 120 by 80 cm [40 by 48 in.] and a height of up to 2 m [6.5 ft.],” said Anders Billesø Beck, vice president of strategy and innovation at Universal Robots. “We did this while keeping the footprint small and making the arm both slimmer and longer.”

The company developed the new product in response to customer requests, he told Robotics 24/7. While some cobot users have looked at using two arms, more were interested in increased reach and payload capacity, as well as in maximizing space usage for brownfield installations, Beck said. The UR20 weighs 64 kg (141.1 lb.).

In addition, the new robot arm includes motion-control algorithms and vibration suppression to ensure smooth movement between setpoints for its size, he noted. It works with UR's 3PE teach pendant, the existing PolyScope programming software, and a standard 110-220 VAC power outlet, said Beck.

With faster, smaller wrists and design for uptime, the UR20 is intended to be both safer and more flexible than its predecessors, he added.

“It has an all-new joint design for 65% faster cycle times and a 50% reduction in parts, and it is suitable for machine tending, materials handling, and welding in addition to palletizing,” Beck explained. “We also designed a wider tool flange for the corresponding end effectors.”

Universal Robots reaches for new applications

Povlsen noted that global labor and skills shortages, as well as an estimated 22 million jobs with automatable tasks present a “real opportunity” for cobots, with only 2% penetration of the potential market.

The UR20 will complement the existing e-Series cobots, and simulation tools are coming, according to Universal Robots. Potential users of the UR20 with UR+ certified URCaps applications include the automotive, food and beverage, and logistics industries, said Beck.

“Our commitment to every customer’s success is reflected in the effort we put into creating our products, and the development of the UR20 is a perfect example of this,” said Povlsen. “We are dedicated to quality engineering, stunning Nordic design, and an outstanding user experience, from software to endcaps.”

“The UR20 is just the beginning,” he said, suggesting that more models are coming. “We’re launching our next generation with this high-payload model first to market because it will make end-to-end automation a reality for our customers, allowing them to use cobot automation to cover new tasks.”

“The next step in redefining automation will be to bring the same innovative features to a new family of cobots,” Povlsen said. “So, watch this space—we can’t wait to show you what the future holds.”

Beck noted that Universal Robots is already working with partners on grippers to handle heavier loads and other products. “When the UR20 comes to market, they should already have accessories,” he said.

Universal Robots is demonstrating the UR20's palletizing capability with UR+ partner Robotiq at Automatica in Munich this week. The cobot will be available for preorder late in the fourth quarter of this year, and it will begin shipping in Q2 2023, said the company, which did not yet specify pricing.

About the Author

Follow Robotics 24/7 on Linkedin

Article topics

Email Sign Up