The Toyota Research Institute yesterday announced the latest results of its collaborative research program with U.S. academic institutions. This initiative has funded $100 million of research and generated more than 1,250 paper submissions since its inception in 2016, making it one of the world's largest collaborative research programs by an automotive company, said Toyota.

“We are deeply satisfied with the results of our partnerships with this outstanding group of institutions and researchers,” stated Eric Krotkov, who leads the university research program at the Toyota Research Institute (TRI). “We believe that collaboration is the key to tackling society's biggest challenges and are confident that this program will continue to achieve new breakthroughs.”

Led by Dr. Gill Pratt, TRI said its reseachers are focused on developing technologies to amplify human ability, make people's lives safer, and improve sustainability. Established in 2015, the institute has offices in Los Altos, Calif., and Cambridge, Mass.

TRI university research program grew in 2022

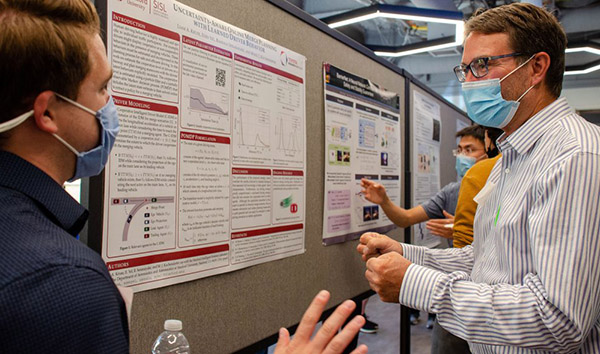

Toyota Research Intitute said its program expanded last year to include 21 university partners and 61 projects focused on robotics, machine learning, energy and materials, human-centered artificial intelligence, and human-interactive driving.

Each project consists of a TRI researcher working with a university team in a close collaboration bridging academia and industry.

“TRI's collaborations with universities bring a wealth of knowledge and new ideas to our research efforts,” said Brian Storey, senior director of energy and materials at TRI. “This program both helps us create innovative technologies and fosters the next generation of innovative leaders.”

Three papers won awards at last year's Robotics: Science and Systems Conference (RSS). Some project highlights from the program include:

Advanced robotic capabilities

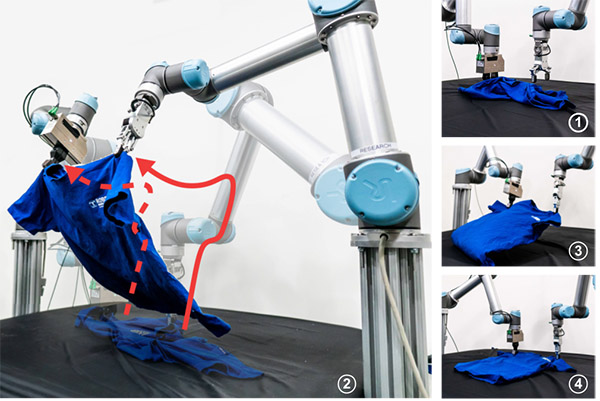

The Columbia Artificial Intelligence and Robotics (CAIR) Lab led by Shuran Song, an assistant professor of computer science, partnered with TRI to develop robotic capabilities that can handle deformable, non-rigid objects that can fold, bend, and change shape. These advancements were successfully tested by having robots fold laundry and manipulate flexible bags.

Shuran's team won a Best Paper Award at RSS 2022 for developing an algorithm called the Iterative Residual Policy (IRP), a general learning framework for repeatable tasks with complex dynamics.

“Working with TRI has been an incredible experience,” she said. “The partnership has allowed us to leverage industry-level resources, which have been critical in driving our research forward. I am honored to have the opportunity to work with such a great team, and I am excited to see what we can accomplish together in the future.”

Fuel cell catalyst durability

Both hydrogen fuel cell vehicles and hydrogen electrolyzers require catalyst materials that utilize expensive and rare elements such as platinum and iridium. A long-standing challenge is to find replacement materials that use more abundant elements.

However, all proposed alternatives don't last long in an operating environment before they dissolve, noted the researchers.

The laboratories led by Prof. Thomas Jaramillo at Stanford University and Associate Scientist Michaela Burke Stevens at the Stanford Linear Accelerator Center (SLAC) are working with TRI researchers to create data-driven theories of catalyst durability. They said they are using a novel experimental technique that enables real-time measurement of even the smallest amounts of dissolving materials.

Computational governor

Prof. Ilya Kolmanovsky's research team at the University of Michigan developed a governor architecture that could be used to speed up the execution time of a model predictive control (MPC) system. TRI said its researchers collaborated on and took inspiration from this project to create a solution for Toyota Motor Corp. that solves a vehicle controller problem where sudden changes to setpoints would cause unresponsiveness.

“I believe our project is an exemplar of how TRI combines industry and academic knowledge, expertise, and capabilities to develop solutions that ultimately lead to real-world impact,” said Kolmanovsky. “This is, without any doubt, one of the best research collaborations that I have ever had.”

Toyota Research Institute said it plans to continue the program into 2024 “with new additional high-risk, high-reward projects to accelerate the development of key technologies for Toyota.”

Article topics

Email Sign Up