So you want to 3D print in metal? One way is through a standard commercial service bureau, which gives you access to big industrial AM machines. Depending on your application, another approach is to purchase metal-infused filament from The Virtual Foundry to use on your own fused filament fabrication (FFF)-type printer. And a third option is to buy one of the up-and-coming office-level metal systems, such as the Markforged Metal X or one of the systems underway from Orlas, Desktop Metal and Freemelt.

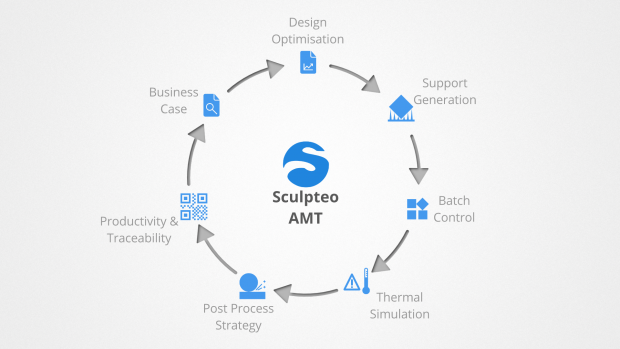

Sculpteo has launched the first of six interactive tools in its Agile Metal Technology suite for 3D printing with metals. The first is the AMT Business Case that helps users choose material, price and critical parameters. (Image courtesy Sculpteo)

Sculpteo has launched the first of six interactive tools in its Agile Metal Technology suite for 3D printing with metals. The first is the AMT Business Case that helps users choose material, price and critical parameters. (Image courtesy Sculpteo)But still another option is to work through Sculpteo, the online service bureau that has access to industrial AM equipment across the country and offers many material possibilities. The particular bonus? Sculpteo has recently started offering a new design-guidance software suite called Agile Metal Technology (AMT). This value-added package might be just what you need to get started in the metal AM world.

Sculpteo says it is developing AMT to help designers, mechanical engineers and manufacturers “get their metal AM projects on track,” tackling what it sees as the major roadblocks in this field. The suite comprises six online tools on track for roll-out over the next few months, of which AMT Business Case is the first.

AMT Business Case – 3D-Printing Guidance

Sculpteo says AMT Business Case is a self-learning, AI-based decision tree that steps users through up to 35 questions about the proposed part: its application, the critical parameters (including tolerance, price-range, surface roughness and desired delivery date), and how much force (if any) will be applied to it. It then generates a list of possible materials for production, the range of prices across that list and a proposed delivery date. Sample question from Sculpteo’s interactive online tool, AMT Business Case. Your answers to more than 30 questions help the AI-guided software suggest optimum printing decisions. (Image courtesy Sculpteo)

Sample question from Sculpteo’s interactive online tool, AMT Business Case. Your answers to more than 30 questions help the AI-guided software suggest optimum printing decisions. (Image courtesy Sculpteo)All of this is possible just by the user uploading a 3D CAD file in one of 40 file types, with STL still the most common. I did my own trial run for a small keychain medallion with raised lettering, and received quite a thorough evaluation—a list of “good news” and “issues to review.”

Among the good: it confirmed that my design had a sufficient polygon count for manufacturing, the dimension constraints were acceptable, and my allowable lead time was realistic.

However, for my choice of aluminum (AlSi10Mg), the calculated budget was 2.8x my requested price (OK, I was hoping for a $20 item, but this really wasn’t realistic). I also had not specified a desired tensile value, so the tool simply cautioned its strength analysis might not be complete (not a concern for me). Lastly, the Business Case summary noted that I had 15 thin points, which might make the item fragile.

I had a few questions about AMT’s operations and my test case. Clement Moreau, Sculpteo’s CEO, kindly clarified them for me:

- In order to be useful for newbies as well as experienced users, the tool starts out at a top level by confirming whether you want metal, polymer or other material.

- If you create an account and log in, your 3D model shows up as a rotating image, with any noted thin point highlighted either singly or all at once. This feature alone makes the tool valuable, as it provides guidance for you to edit the design in just the important spots, and try again.

- I found by experimenting that as you go through the Business Case steps, you can go back to change answers and try a different choice; however, you can’t save your work partway through, to return later. Moreau says this may be a future option.

Beyond the Business Case Tool

Sculpteo’s AMT suite will soon include the following:- Smart Design Optimizer, providing a deeper analysis of the design’s compatibility for metal AM. It will assess the best way to handle thermal problems and will suggest the best build orientation.

- Automatic Lattice Generator, which will evaluate the expected forces, suggest structural changes, and produce internal lattice structures to reduce weight and cost.

- Support Generator, an interactive tool that will guide the user in creating any necessary support structures. Experts will be able to add restrictions and other inputs.

- Post-Processor, an intriguing tool that addresses what many new users fail to consider: the need for various post-processing steps. It calculates a timeline and additional budget for adding in such requirements as drilling, threading, grinding and polishing.

- Batch Control for Metal extends Sculpteo’s existing Batch Control for Polymers tool. Users gain virtual machine control, allowing them to set up production batches that fit their schedule and use their own previously optimized printing parameters.

Sample titanium part produced through the Sculpteo online service on a direct metal laser sintering system. (Image courtesy Sculpteo)

Sample titanium part produced through the Sculpteo online service on a direct metal laser sintering system. (Image courtesy Sculpteo)Bonus: Scroll down to the bottom of the Sculpteo homepage to access the company’s selection of interactive tools and tutorials. The design guidelines alone for various materials (e.g., glass-filled nylon) are so down-to-earth and helpful it’s worth reading/viewing all of them. There are even tutorials on preparing your 3D CAD model for printing specifically using Inventor, CATIA, SOLIDWORKS, Blender, Sketch-up, Meshmixer and more.

Stay tuned as Sculpteo rolls out the rest of its AMT capabilities.

About the Author

Follow Robotics 24/7 on Linkedin

Article topics

Email Sign Up