Renewable energy technology manufacturer Sumitomo SHI FW is working with Gecko Robotics to help it with inspections and other service tasks.

Since July, the Espoo, Finland-based company has been using Gecko’s wall-climbing robots to service and maintain boilers in Austria, Bulgaria, Germany, Poland, Romania, Brazil, and the Czech Republic. It has now extended the partnership and will use Gecko’s robots worldwide.

Reptilan robots reduce safety risks, offer more data

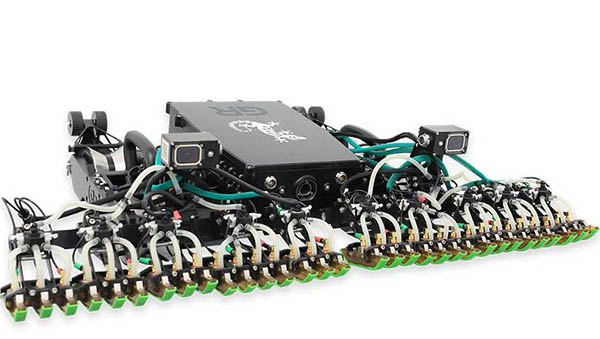

Based out of Pittsburgh, Gecko Robotics said its robots are designed for “non-destructive inspections” and can climb tanks, boilers, pipes, and more, according to the company’s website.

Gecko’s team will inspect circulating fluidized bed (CFB) boilers and bubbling fluidized bed (BFB) boilers using what it calls Rapid Ultrasonic Gridding, which pinpoints corrosion and wall loss. Using this integrity data, Sumitomo SHI FW can help asset owners adjust operations and offer maintenance and service recommendations.

“Together, we are bringing the best of both worlds to CFB boiler operators across the globe - unparalleled boiler operations and maintenance expertise from SFW and ability to capture boiler condition in the finest detail with GR robots,” said Ivan Pistsov, head of international partnerships at Gecko Robotics.

Gecko Robotics was founded in 2013. It said its robots help minimize work-related injuries and offer much more comprehensive data than traditional systems.

“The data allows the owner to better diagnose equipment damage and predict future life. This results in better-targeted maintenance, lower costs, higher up time, and, most importantly, fewer deaths and injuries,” according to a statement from the company.

lkka Koskinen, director of service agreements and digital services at Sumitomo SHI FW, said she is excited to expand the company's partnership with Gecko on a global scale. It will help the company offer more services.

“Accurate inspection data also supports our Digital Services and enables us to enrich advanced analytics to boost boilers’ performance without added risk,” Koshskinen said.

Sumitomo said it offers best in class energy and environmental technologies.

“Our solutions expand from our world leading circulating fluidized bed (CFB) technology, to long duration energy storage solutions (Liquified Air Energy Storage, CryoBattery), flue gas cleaning, gasification, waste heat boilers and a full spectrum of services for the global power and industrial markets,” reads an excerpt from the company's LinkedIn page.

It is part of Sumitomo Heavy Industries Ltd.

CFB/BFB boilers cut greenhouse gases

Old, obsolete boilers can also be converted to CFB/BFB boilers, thus enabling power plant operators to reduce CO2 emissions. In addition to environmental sustainability, maintaining high reliability is critically important for asset owners. To do this, they need to be well equipped to inspect and maintain their infrastructure, according to Sumitomo SHI FW.

Article topics

Email Sign Up