Additive manufacturing (AM) offers a number of advantages over existing manufacturing methods, including flexibility and material savings. Companies that have taken the time to fully integrate AM have found additional ways to ensure ROI, including 3D printing manufacturing tools.

In theory, the workshops of the future won’t need dedicated tool rooms that cover every possible need. Rather, they will maintain a digital tool room that allows them to print a needed tool upon demand. Stratasys is helping make that future idea a current reality with the launch of its Manufacturing Aids Package for the Fortus 900mc.

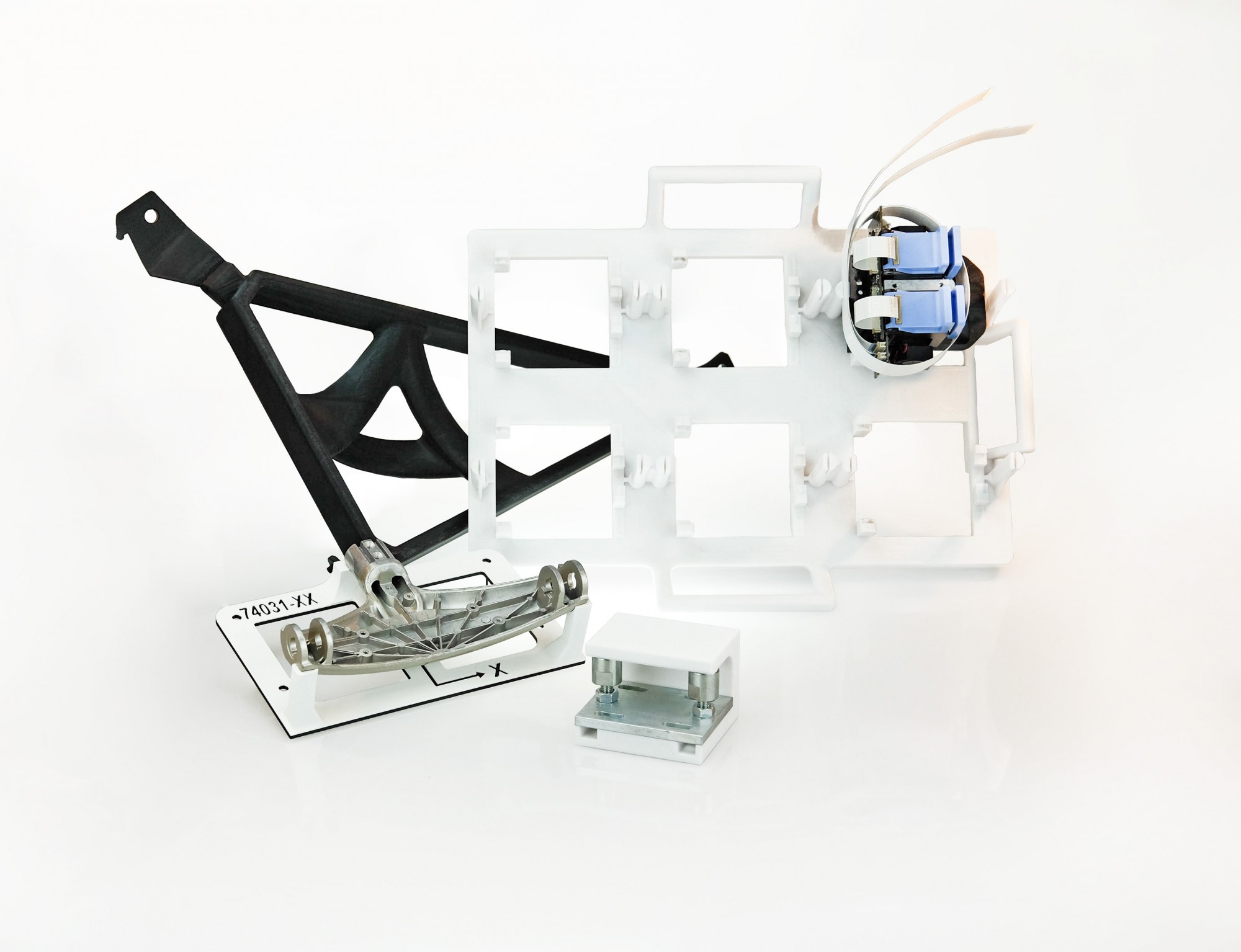

Custom manufacturing tools produced from ASA, PC and new Nylon 6 thermoplastic material. All three materials are part of the Manufacturing Aids Package for the Fortus 900mc Production 3D printer. Courtesy of Stratasys.

Custom manufacturing tools produced from ASA, PC and new Nylon 6 thermoplastic material. All three materials are part of the Manufacturing Aids Package for the Fortus 900mc Production 3D printer. Courtesy of Stratasys.“3D printing jigs and fixtures enables manufacturers to improve these tools’ usability and ensure their availability,” says Stratasys’ Sanja Wallace. “The ability to design a manufacturing aid specifically for a given task and produce it on demand is a huge benefit. And producing these tools from lightweight thermoplastics instead of metal makes them much easier to use and more cost-effective to produce.”

In this particular case, Stratasys is highlighting the potential to print lightweight tools, such as custom jigs and fixtures. The package includes 40 hours of design work from Stratasys, along with six canisters of thermoplastic build material and three canisters of support material. Materials include Nylon 6, PC, and ASA plastic. Along with build materials, Stratasys has also packed its new SR-35 soluble support material.

As a final bit of encouragement to find new ways to leverage the Fortus 900mc, the package also includes the option to extend the factory warranty by two years.

Along with the flexibility of printing tools on demand, once the life of a tool has ended, it can often be recycled or even “retooled” by printing new iterations. A company that chooses to use 3D printed tools can also save on the time required to build a tool off-site, even given the relatively slow print times involved with some builds.

Below you’ll find a video about the Fortus 900mc.

Source: Stratasys

About the Author

Follow Robotics 24/7 on Linkedin

Article topics

Email Sign Up